Wet-preparation process for mancozeb water dispersible granules

A mancozeb, preparation process technology, applied in the directions of biocides, fungicides, biocides, etc., can solve the problem that the wet suspension agent is not easy to store and transport, the cylindrical solid dispersant has poor water dispersibility, and the wet powder has strong pollution, etc. problems, to achieve high development prospects and value, good social and economic benefits, and the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A wet preparation process of mancozeb water-dispersible granules, the above process steps include dehydrating the wet material of mancozeb, and the above process steps also include:

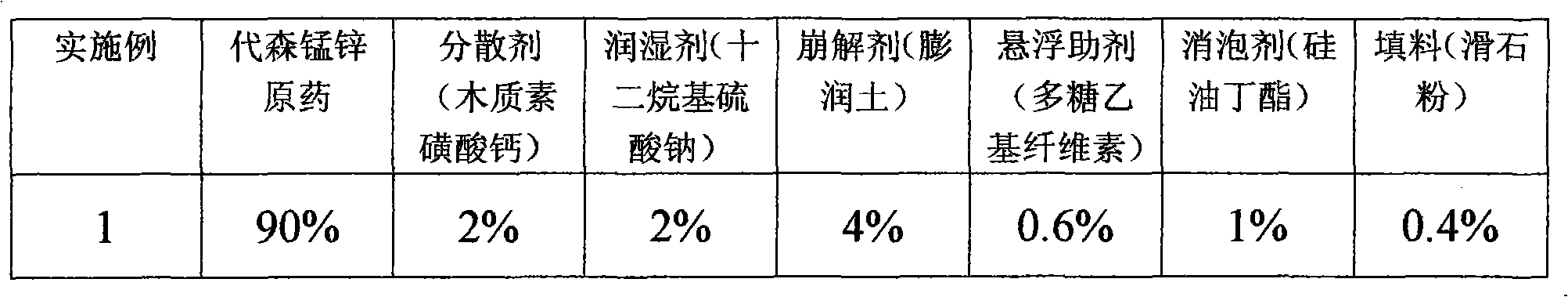

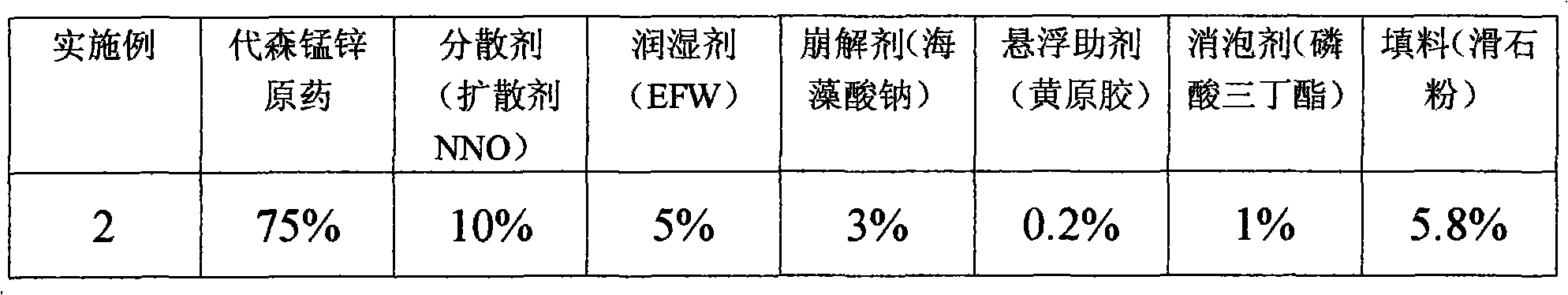

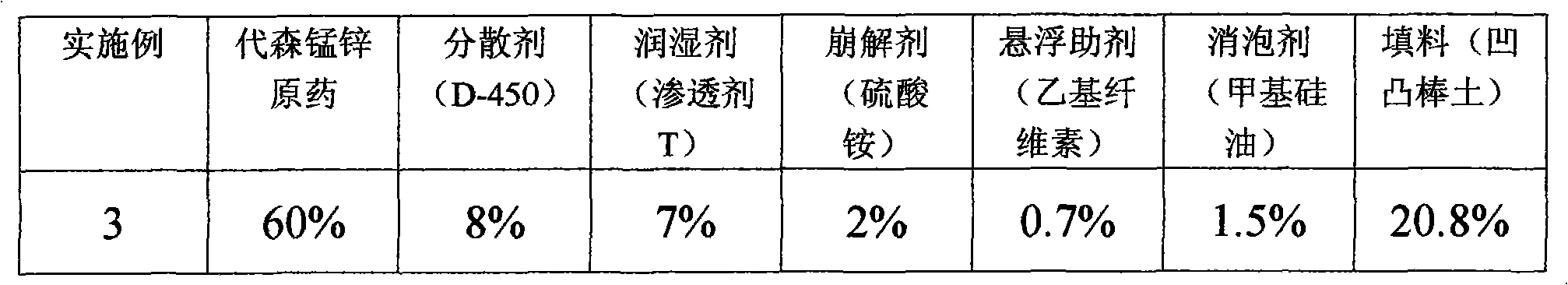

[0021] A. Ingredients: After converting the dehydrated mancozeb wet material into the effective content, the formula is as follows:

[0022] Mancozeb 40~90%

[0023] Dispersant 1~20%

[0024] Wetting agent 1~20%

[0025] Disintegrant 1~20%

[0026] Suspending aid 0.01~10%

[0027] Defoamer 0.01~10%

[0028] The rest is filler

[0029] B. Add water to the ingredients and make a slurry;

[0030] C. Grinding: transport the slurry to a sand mill for grinding;

[0031] D. Transport the sand-milled slurry to the spray granulation tower for spray granulation to form mancozeb granules;

[0032] E. Sieve according to the fineness of the particles and pack them into products.

[0033] In the above step C, the particle size of mancozeb should be less than 5 μm.

[0034] In the above step A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com