Watermelon ketone synthesizing process

A synthetic process, the technology of watermelon ketone, applied in the field of synthetic watermelon ketone, to achieve the effect of reducing production cost, low boiling point, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

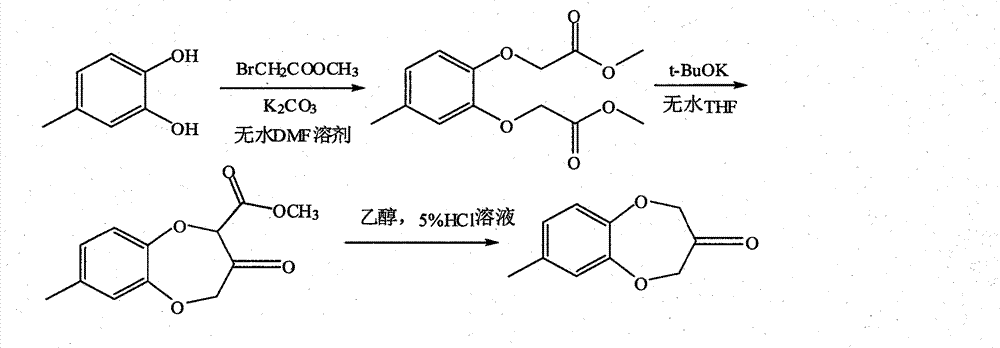

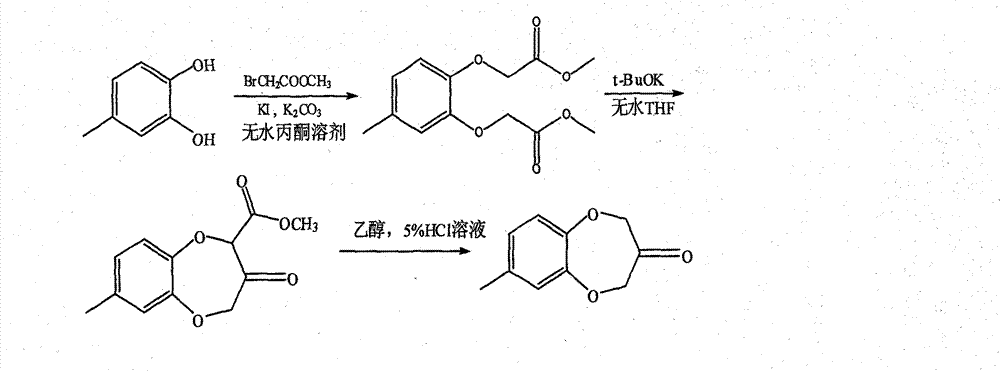

Method used

Image

Examples

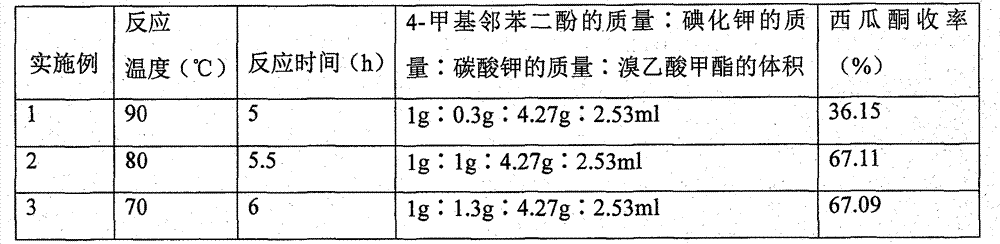

Embodiment 1

[0033] The concrete steps of a kind of synthesis technique of watermelon ketone are as follows:

[0034] (1) Williamson condensation reaction

[0035] Potassium iodide is used as a catalyst, and potassium iodide is first dissolved in anhydrous acetone solvent to prepare a potassium iodide catalyst solution. The potassium iodide catalyst solution was then placed in the dried reflux reaction vessel, heated to 90° C., and then methyl bromoacetate was added dropwise. After the dropwise addition, potassium carbonate and 4-methyl catechol were added in turn, and After completion, the Williamson condensation reaction was carried out by stirring and refluxing at a constant temperature of 90° C. for 5 h, and the Williamson condensation reaction suspension was prepared. Wherein: the quality of potassium iodide: the volume ratio of anhydrous acetone solvent is 1g: 20ml; the quality of 4-methylcatechol: the quality of potassium iodide: the quality of potassium carbonate: the volume ratio...

Embodiment 2

[0050] A kind of concrete steps of the synthesis technique of watermelon ketone, with embodiment 1, wherein:

[0051]In the (1) step, the heating temperature in the reflux reactor is 80°C, and the Williamson condensation reaction is carried out under stirring and refluxing at a constant temperature of 80°C for 5.5h, wherein: the mass of potassium iodide: the volume ratio of anhydrous acetone solvent is 1g: 25ml ; The mass of 4-methylcatechol: the mass of potassium iodide: the mass of potassium carbonate: the volume ratio of methyl bromoacetate is 1g: 1g: 4.27g: 2.53ml.

[0052] In step (2), rotary evaporation is performed at 45° C. to remove the anhydrous acetone solvent, and the collected evaporation residue is washed with a 5% sodium hydroxide solution until the pH value is 8.5. The washed mixture was extracted with 15 times the volume of dichloromethane. The collected lower dichloromethane solution was back-extracted with 15 times the volume of water. Anhydrous sodium sul...

Embodiment 3

[0054] A kind of concrete steps of the synthesis technique of watermelon ketone, with embodiment 1, wherein:

[0055] In the (1) step, the heating temperature in the reflux reactor is 70 ℃, and stirring and refluxing at 70 ℃ constant temperature carries out Williamson condensation reaction 6h, wherein: the quality of potassium iodide: the volume ratio of anhydrous acetone solvent is 1g: 30ml; The volume ratio of the mass of 4-methylcatechol: the mass of potassium iodide: the mass of potassium carbonate: methyl bromoacetate is 1 g: 1.3 g: 4.27 g: 2.53 ml.

[0056] In step (2), rotary evaporation is performed at 50° C. to remove the anhydrous acetone solvent, and the collected evaporation residue is washed with a 5% sodium hydroxide solution until the pH value is 9. The washed mixture was extracted with 20 times the volume of dichloromethane. The collected lower dichloromethane solution was back-extracted with 20 times the volume of water. Anhydrous sodium sulfate was added to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com