Salt-restraining special fertilizer for seashore solonchak rapes and production process thereof

A special fertilizer and rapeseed technology, which is applied in the field of special salt-suppressing rapeseed fertilizer and its production technology in coastal saline soil, can solve the problems of high cost, seasonal salt return, eutrophication of surrounding water body, soil salt accumulation, etc., and achieve reduction of control times and Dosage of chemicals, growth promotion and regulation, effect of promoting flower bud differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

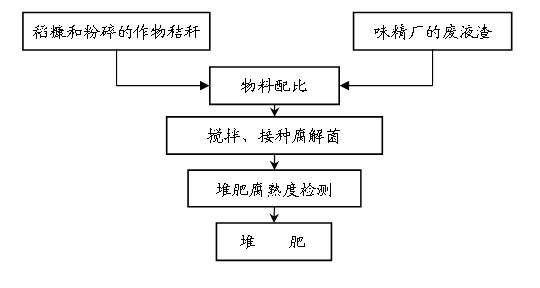

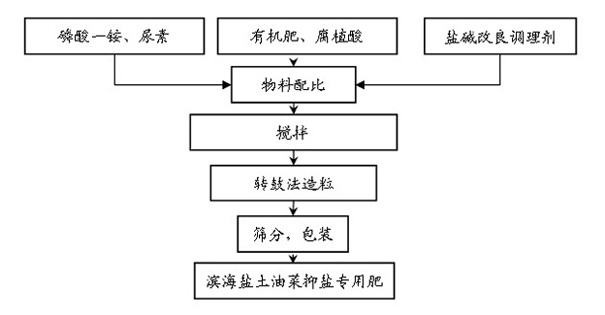

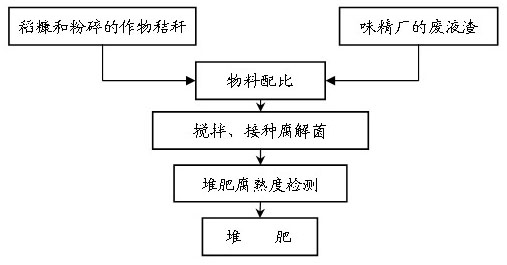

[0031] The preparation steps are as follows: mix the crushed crop straw, rice bran and the waste liquid slag of the monosodium glutamate factory according to the weight ratio of 1:1:2 and pile them up; (provided by Nanjing Agricultural University, the main components are cellulolytic bacteria, bacillus, yeast and mold), stir and mix evenly; when the temperature of the pile rises to 55~65℃, turn the pile, after 14~17 days, The heap body reaches a decomposed state, at this time, the water content is 26-35%, and the organic fertilizer is obtained; according to the proportion of parts by weight, 160 kg of monoammonium phosphate, 200 kg of urea, 150 kg of humic acid, 300 kg of organic fertilizer, and saline-alkali improvement Add 190 kg of conditioner to the mixer in order to stir, and after mixing, feed the material to the drum granulator for granulation; the granulated fertilizer is sieved and packaged to obtain the finished salt-inhibiting fertilizer for rape in coastal sa...

Embodiment 2

[0035] After the raw materials are prepared in proportion, they are granulated by drum method. During the granulation process, the granulation effect is adjusted by water to make it meet the national organic and inorganic compound fertilizer standards. The amount of the above two formulas can produce 1000 kg of finished special fertilizer, the nutrients are 12-8-0, and the contents of organic matter and amino acid are respectively above 20% and 1%, the content of gypsum is above 10%, and it contains 2 kg of borax. On the coastal saline soil with moderate salinization, applying 50 kg of salt-inhibiting special fertilizer per mu in the form of base fertilizer, and other cultivation and management measures can enhance the saline-alkali resistance of rapeseed, and increase the yield by an average of 10% compared with traditional fertilization. At the same time, it can significantly reduce Na in the surface soil during the growth period of rape + and Cl - content, with an ...

Embodiment 3

[0039] The preparation steps are as follows: mix the crushed crop straw, rice bran and the waste liquid slag of the monosodium glutamate factory according to the weight ratio of 1:1:2 and pile them up; (provided by Nanjing Agricultural University, the main components are cellulolytic bacteria, bacillus, yeast and mold), stir and mix evenly; when the temperature of the pile rises to 55~65℃, turn the pile, after 14~17 days, The heap body reaches a decomposed state, at this time, the water content is 26~35%, and the organic fertilizer is obtained; according to the ratio of parts by weight, 170 kg of monoammonium phosphate, 220 kg of urea, 200 kg of humic acid, 300 kg of organic fertilizer, and saline-alkali improvement Add 200 kg of conditioner to the mixer and stir in turn. After mixing, feed the material to the drum granulator for granulation; the granulated fertilizer is sieved and packaged to obtain the finished salt-inhibiting fertilizer for rape in coastal saline soil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com