Baffling tank type supercritical water treatment reactor with sacrificial lining

A supercritical water and reactor technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of catalyst loading, replacement difficulty, reduction of reactor service life, ammonia nitrogen oxidation, etc. Difficulties and other problems, to achieve the effect of simple installation and replacement, reducing production costs, and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

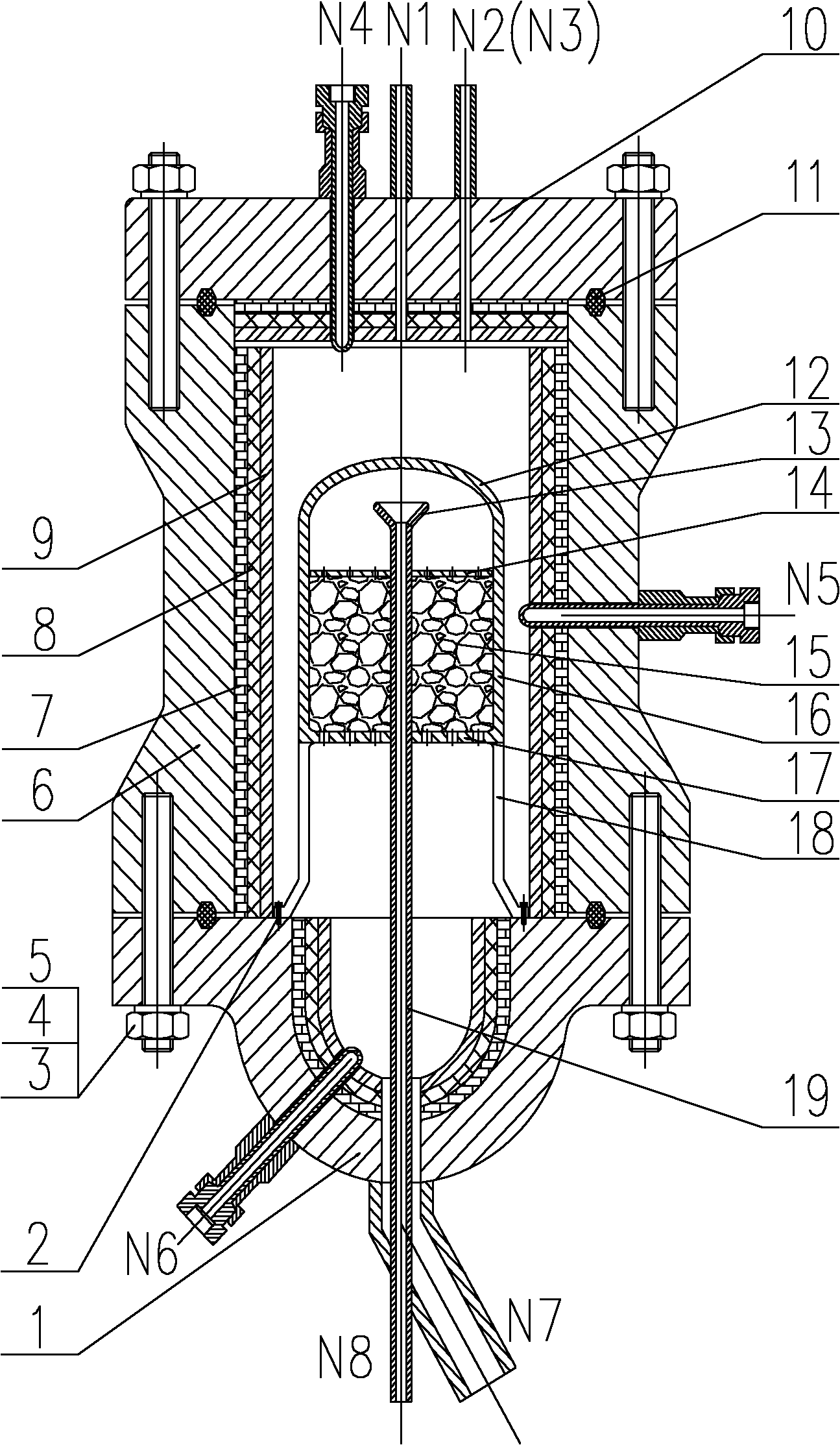

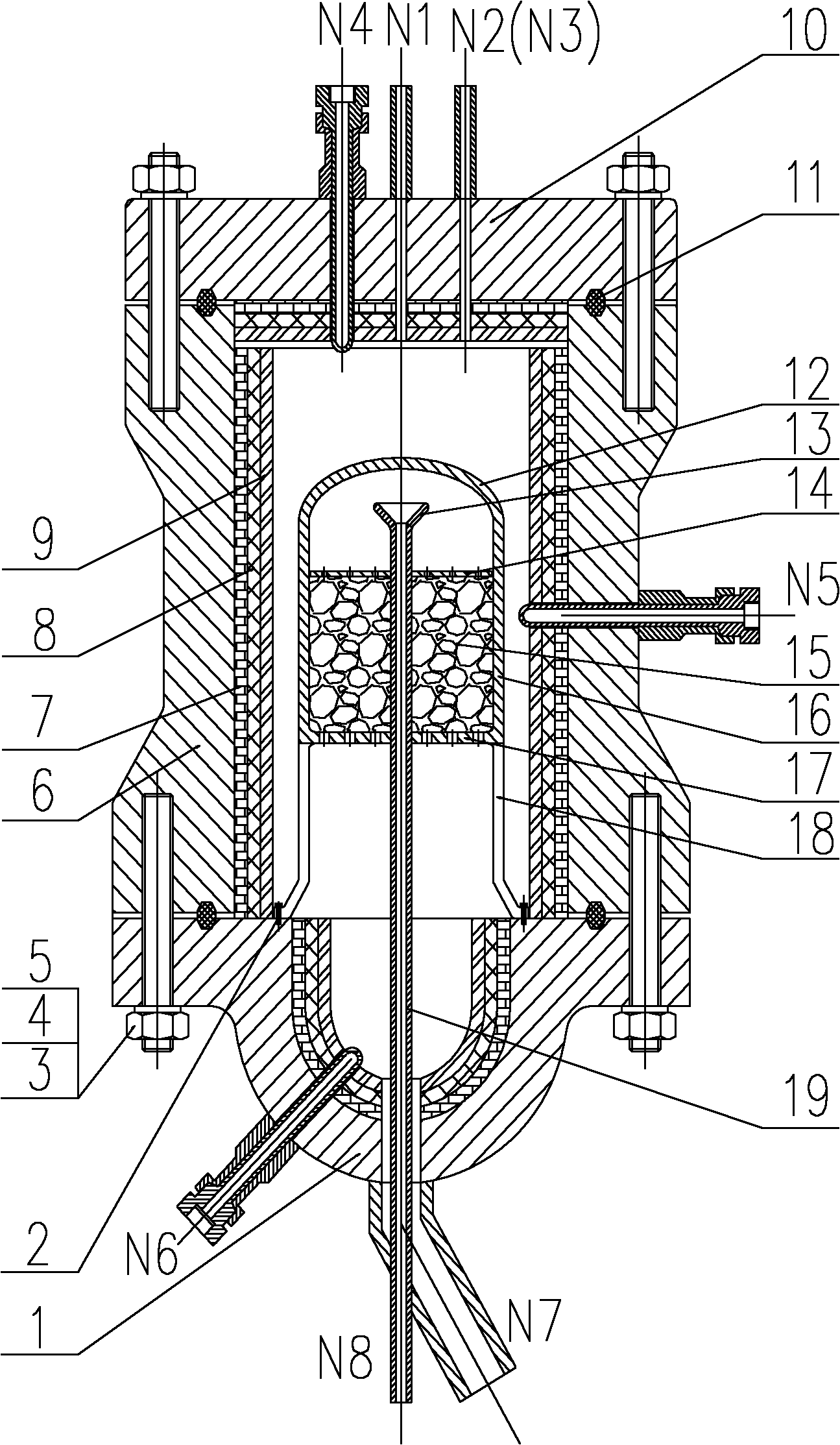

[0022] Such as figure 1 As shown, a baffle tank type supercritical water treatment reactor with a sacrificial lining includes a cylinder 6 and a catalyst box arranged therein, the top of the cylinder 6 is connected with a top cover 10, and the bottom of the cylinder is connected with There is a spherical head 1, the inside of the cylinder, the inside of the spherical head and the inside of the top cover constitute the inner wall of the reactor, and a high temperature resistant heat insulation coating layer 7 is provided, and a sealing coating layer 8 is provided on the inner wall of the high temperature resistant heat insulation coating layer to seal The inner wall of the paint layer is provided with a sacrificial lining 9 .

[0023] One of the characteristics of this reactor is that it can prevent the corrosion of the reactor wall, as follows:

[0024] 1) The inner wall of the reactor (including the top cover 10, the cylinder body 6 and the spherical head 1) is painted with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com