Method for extracting electrolytic zinc from oxide material containing less than 20% of zinc by using waste acid in titanium white plant

A technology of material and zinc content, applied in the direction of improving process efficiency, can solve the problem of inability to produce electrolytic zinc with industrial-grade sulfuric acid, and achieve the effect of effective development and utilization and reduction of production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

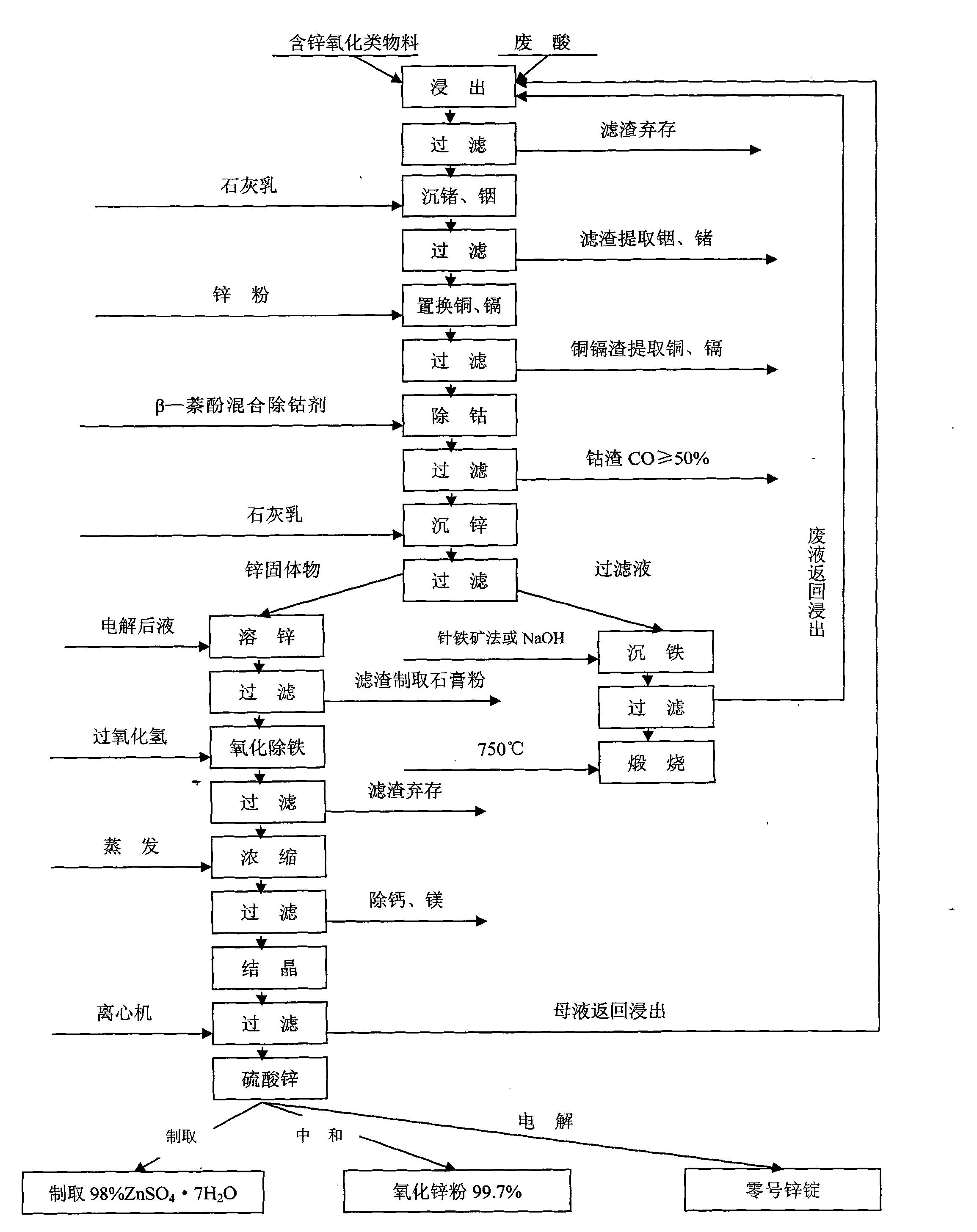

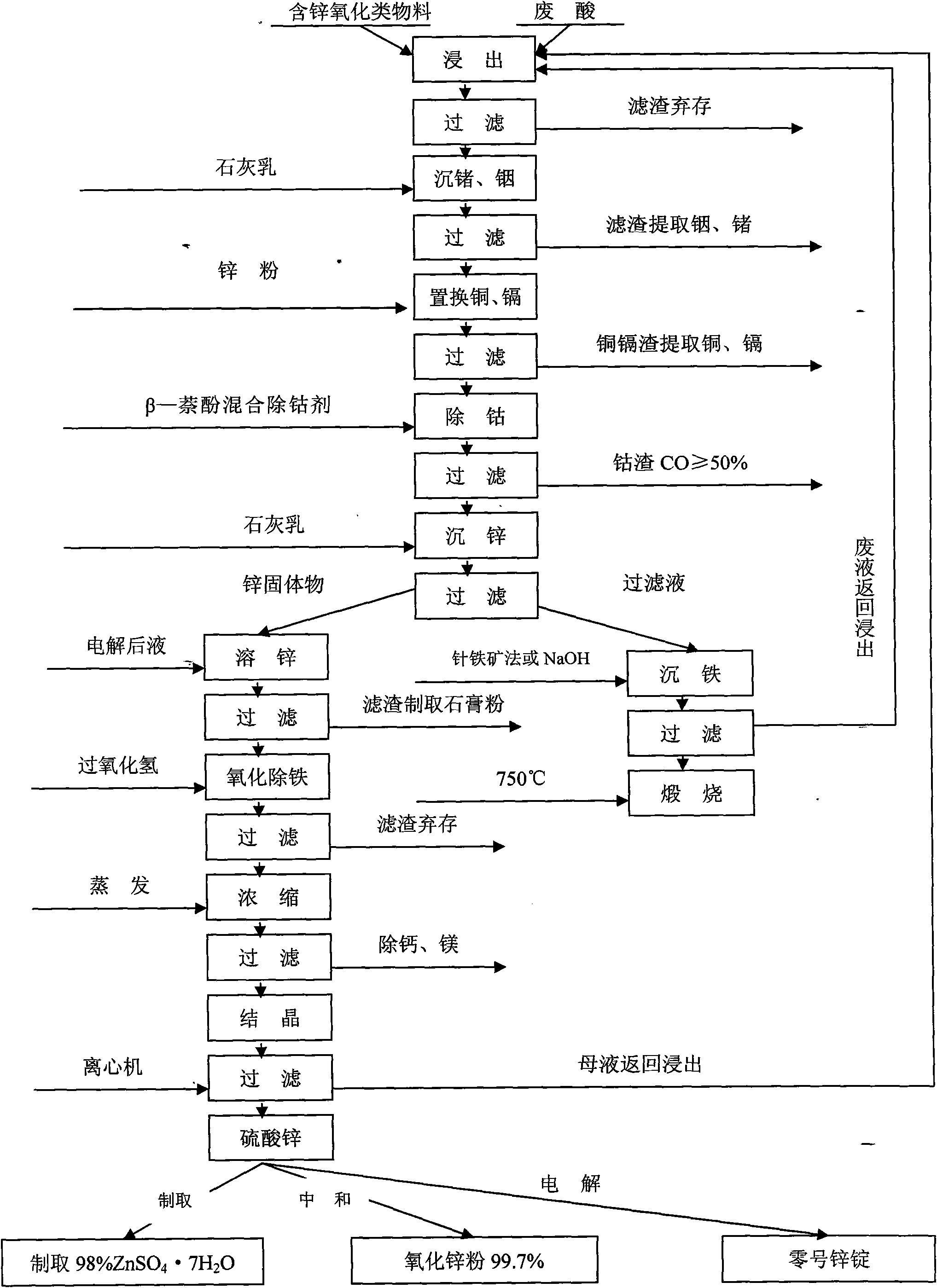

Image

Examples

Embodiment Construction

[0032] Use waste acid from sulfuric acid titanium dioxide factory (content of sulfuric acid is 18-22%) as leaching agent to leach zinc oxide, indium, germanium, copper, cadmium, iron, etc. in oxidized materials with zinc content below 20% metal substance.

[0033] At room temperature, stirring and leaching are carried out at a speed of 60-80 revolutions per minute. The stirring time is 2 to 3 hours, and the amount of waste acid used is 1:4. That is, 1 part of zinc-containing oxidized material, 4 parts of waste acid, and a solid-to-liquid ratio of 1:6, until the pH value of the leaching solution is stabilized below 1.0, and after an extension of 1 hour, the stirring can be stopped. The chemical reaction formula is:

[0034] ZnO+H 2 SO 4 →ZnSO 4 +H 2 o

[0035] In 2 o 3 +3H 2 SO 4 →In 2 (SO 4 ) 3 +3H 2 o

[0036] GeO+H 2 SO 4 →GeSO 4 +H 2 o

[0037] CdO+H 2 SO 4 →CdSO 4 +H 2 o

[0038] CuO+H 2 SO 4 →CuSO 4 +H 2 o

[0039]Iron mainly comes from wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com