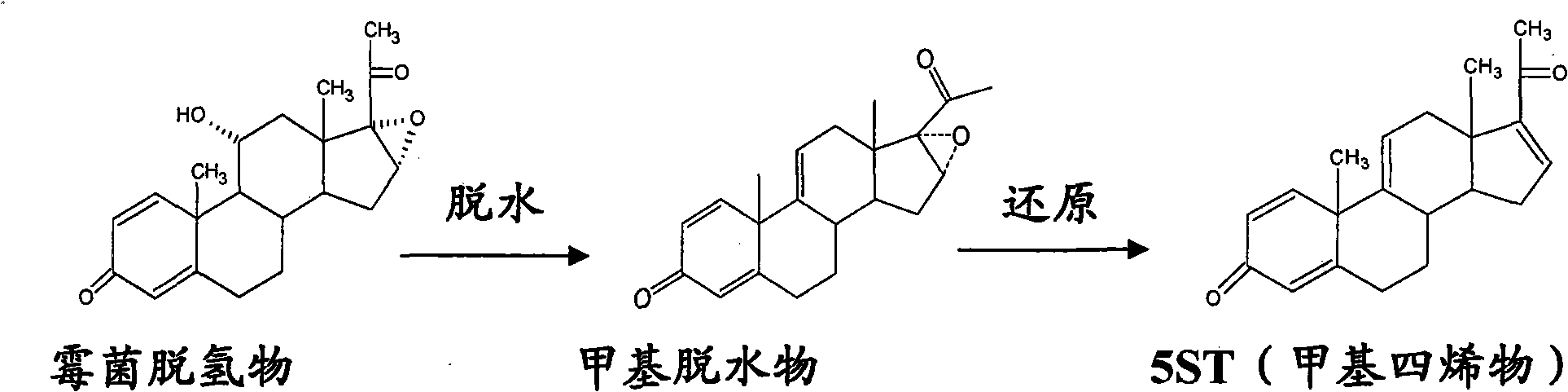

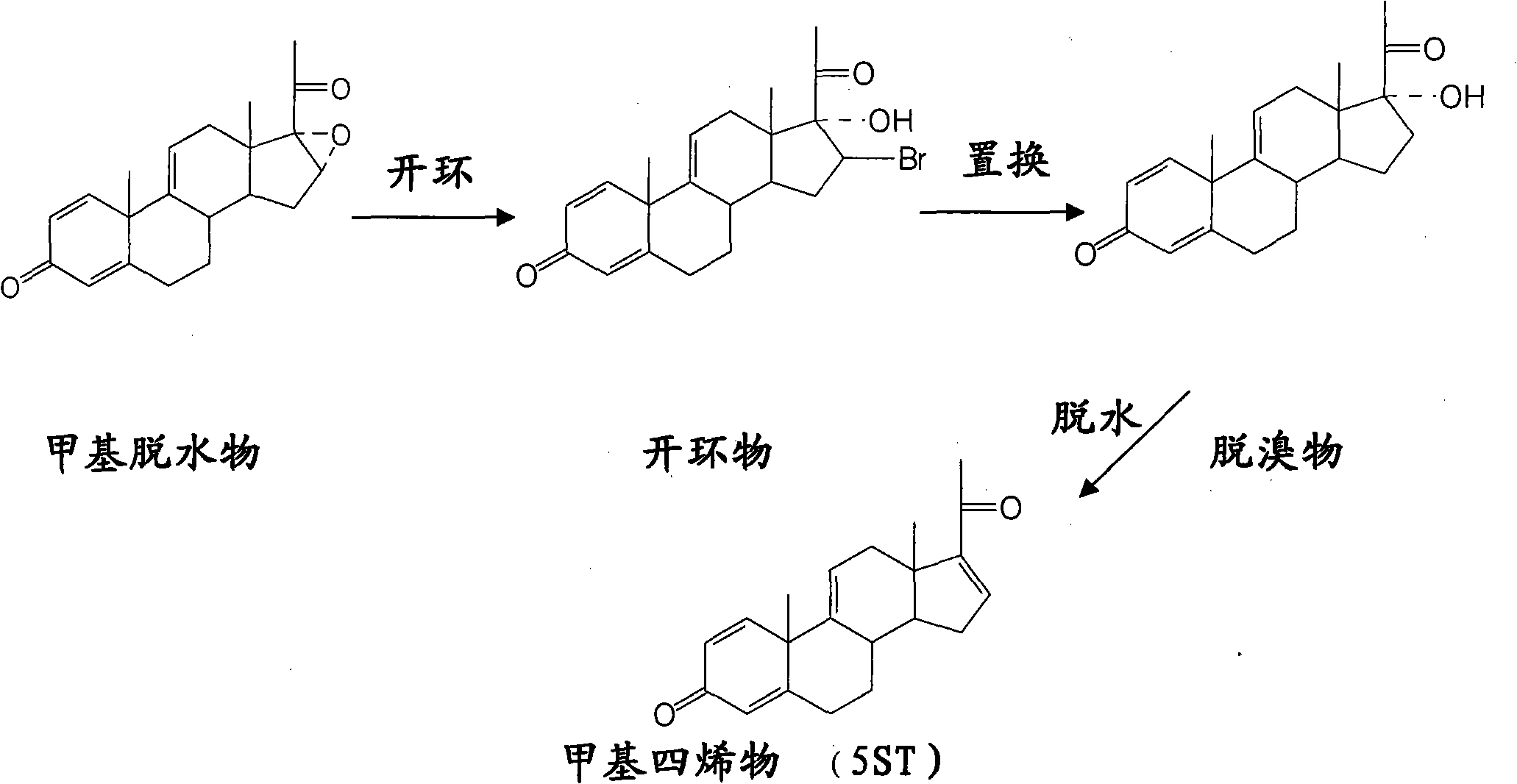

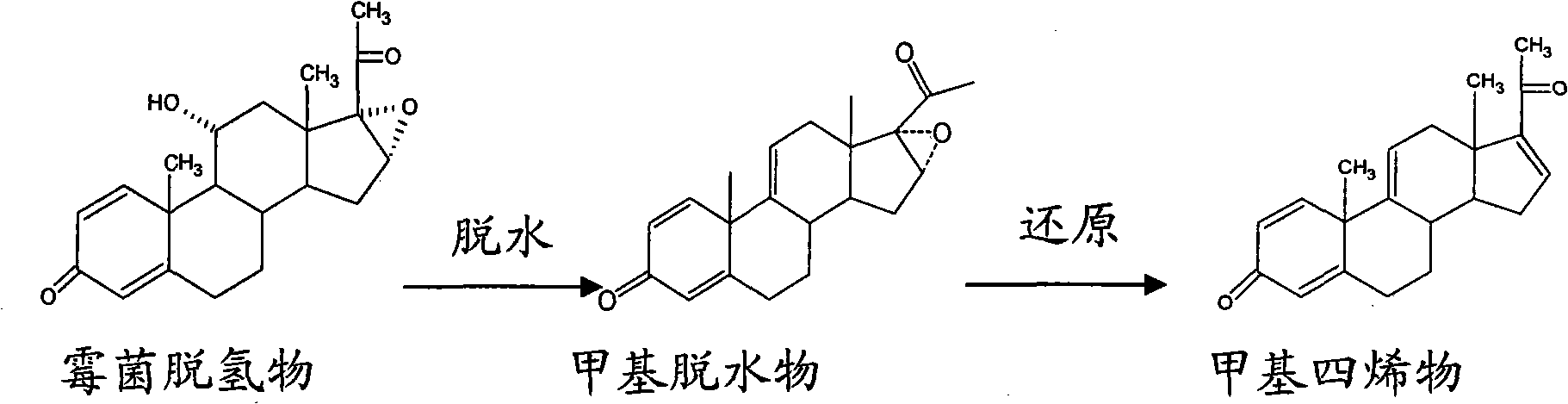

Method for producing important steroid hormone dexamethasone methyl tetraenes intermediate

A technology of isomethyltetraene and dexamethasone is applied in the production field of important intermediate methyltetraene, which can solve the problems of severe conditions, flammable and explosive materials, poor product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 30g of mold dehydrogenation product and 280ml of solvent tetrahydrofuran into the reactor, lower the temperature to -50°C, keep this temperature, add 30g of new dehydrating agent phosphorus pentachloride, and keep it warm for 3.5 hours until it is identified by thin layer chromatography (TLC). If there is no raw material point, the reaction liquid is dispersed in 50 times of ice water, neutralized with alkali to pH ≈ 7, left standing, filtered, and dried to obtain the dehydrated product. Dissolve the methyl dehydrate in ethanol, use 2 times of chromium trichloride and 0.4 times of zinc powder as the reducing agent, add the reducing agent at a low temperature of -5°C, keep the temperature, react for 1 hour, then concentrate, recover the ethanol, stand still, Shake the material and dry to obtain a crude methyl tetraene product with a dehydration yield of 85.2%, and then refine it to obtain a 5ST fine product with a maximum purity of 0.75%.

Embodiment 2

[0023] Add 30g of mold dehydrogenation product and 180ml of solvent tetrahydrofuran into the reactor, lower the temperature to -50°C, keep this temperature, add 30g of new dehydrating agent phosphorus pentachloride, and keep it warm for 3.5 hours until it is identified by thin layer chromatography (TLC). If there is no raw material point, the reaction liquid is dispersed in 50 times of ice water, neutralized with alkali to pH ≈ 7, left standing, filtered, and dried to obtain the dehydrated product. Dissolve the methyl dehydrate in ethanol, use 5 times of chromium trichloride and 0.4 zinc powder as the reducing agent, add the reducing agent at a low temperature of -15°C, keep the temperature, react for 8 hours, then concentrate, recover the ethanol, let stand, shake Material, drying, the crude methyl tetraene was obtained, the dehydration yield was 85.8%, and then refined to obtain the 5ST fine product, the maximum purity was 0.82%.

Embodiment 3

[0025] Add 30g of mold dehydrogenation product and 220ml of solvent tetrahydrofuran into the reactor, lower the temperature to -60°C, keep this temperature, add 42g of new dehydrating agent phosphorus pentachloride, and keep it warm for 3.5 hours until it is identified by thin layer chromatography (TLC). If there is no raw material point, the reaction liquid is dispersed in 50 times of ice water, neutralized with alkali to pH ≈ 7, left standing, filtered, and dried to obtain the dehydrated product. Dissolve the methyl dehydrate in ethanol, use 9 times of chromium trichloride and 4 times of zinc powder as the reducing agent, add the reducing agent at a low temperature ~ 20°C, keep the temperature, react for 5 hours, then concentrate, recover the ethanol, at 20 Stand still in double diluted water, shake the material, and dry to obtain a crude methyl tetraene product with a dehydration yield of 86.3%, and then refine it to obtain a 5ST fine product with a maximum purity of 0.76%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com