Method and device for pulse aperture injection batch preparation of even particles

A uniform and particle technology, applied in the industrial production field of high melting point particle preparation, can solve the problems of no obvious progress in the preparation of high melting point microparticles, unsuitable for industrial production, low production efficiency, etc., and achieves uniform size, consistent organization and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Batch preparation of uniform solidified particles of copper:

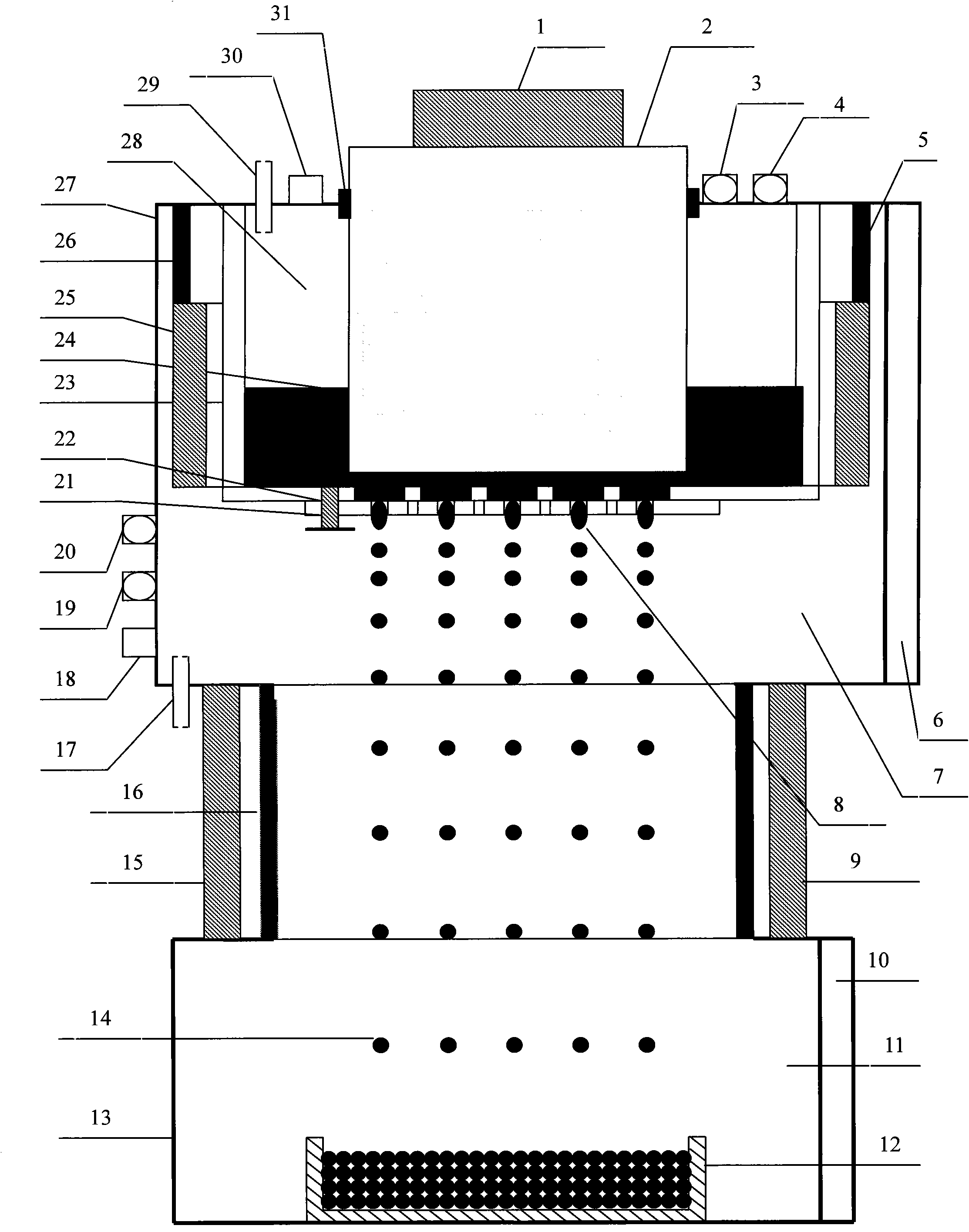

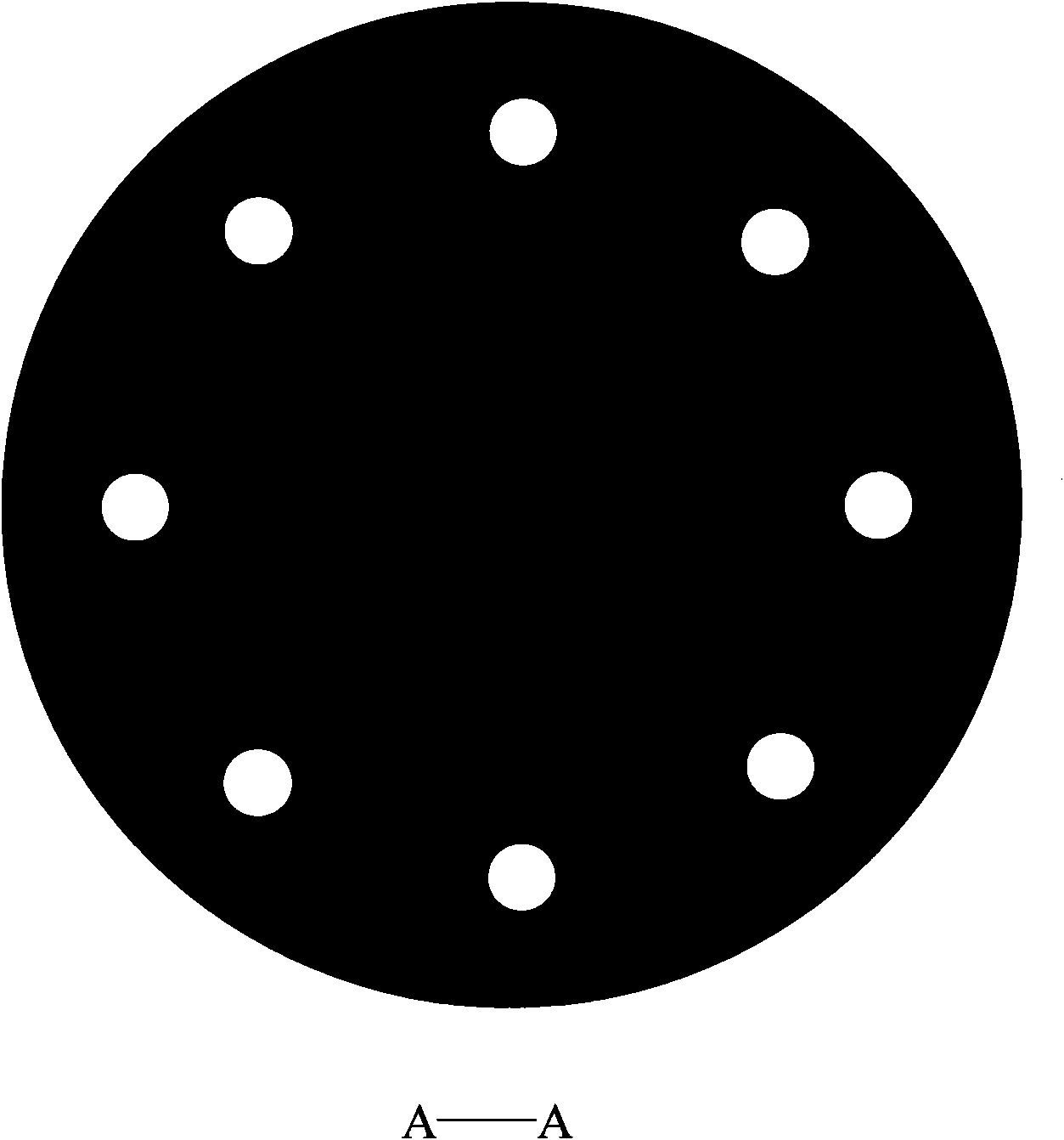

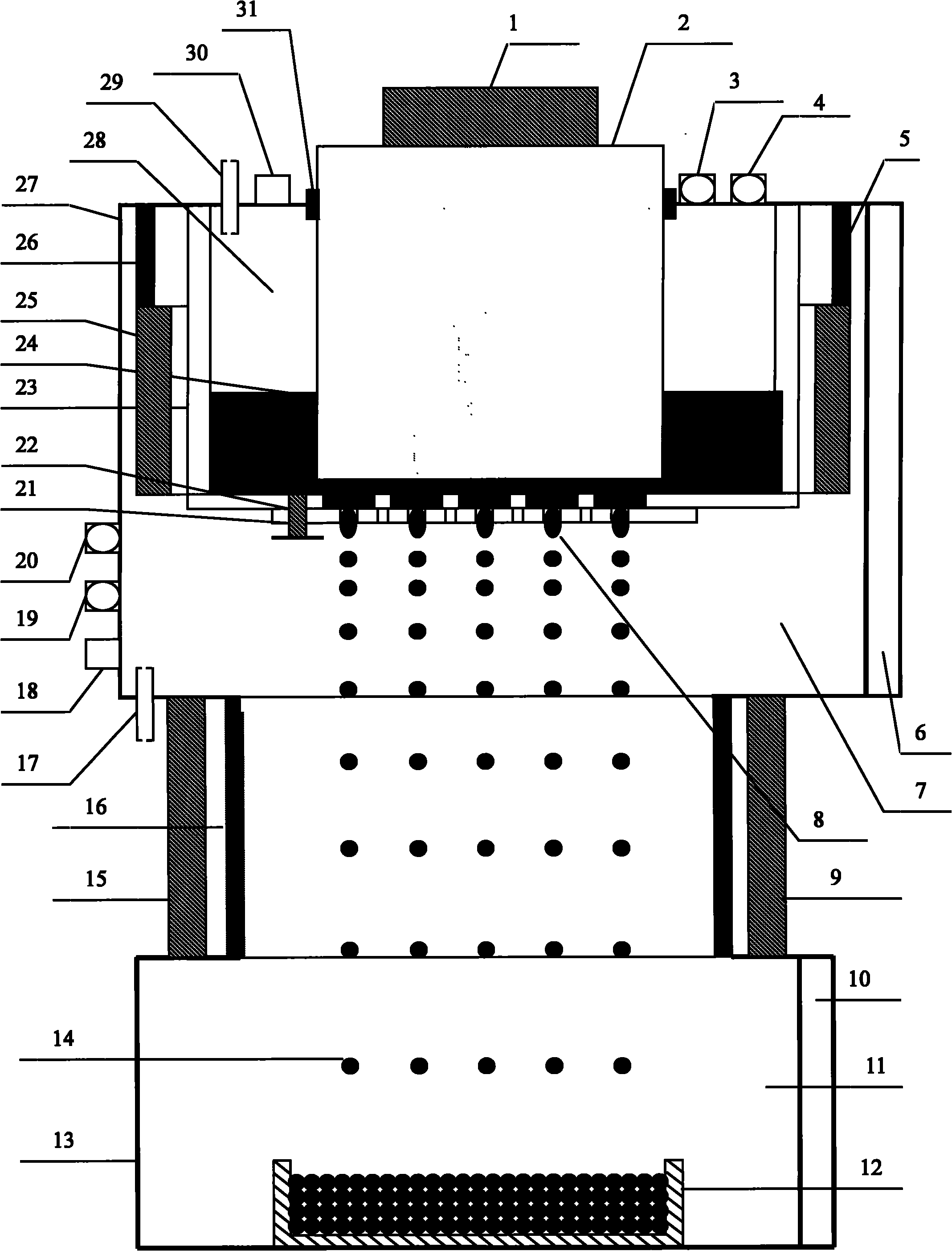

[0028] Devices used such as figure 1 shown. First, the copper block is broken into massive particles with a particle size or an equivalent particle size of 2 cm, and packed into a crucible 23 with holes in the bottom, and the holes are evenly distributed on the same circumference of the bottom of the crucible, such as figure 2 Shown; The charging amount of copper particle reaches 1 / 4 of described crucible 23 capacity, as figure 1 shown; then, the disc 21 made of graphite is installed on the bottom of the crucible 23 with holes through four uniformly distributed screws 22, and the diameter of the disc 21 is larger than the circle formed by the multiple holes on the bottom of the crucible. The diameter of the disc is provided with evenly distributed injection holes; the wetting angle of copper and graphite is 160°; manually adjust the position of the piston rod 2 until the distance between the pis...

Embodiment 2

[0029] Example 2 Batch preparation of uniform solidified particles of silicon:

[0030] Devices used such as figure 1 shown. First, the silicon block is broken into block particles with a particle size or an equivalent particle size of 1 cm, and the broken pieces are packed into a crucible 23 with holes in the bottom, and the holes are evenly distributed on the same circumference of the bottom of the crucible, such as figure 2 Shown; The charging amount of silicon particle reaches 3 / 4 of described crucible 23 capacity, as figure 1shown; then, the disc 21 made of graphite is installed on the bottom of the crucible 23 with holes through four uniformly distributed screws 22, and the diameter of the disc 21 is larger than the circle formed by the multiple holes on the bottom of the crucible. The diameter of the disc is provided with evenly distributed spray holes; the wetting angle between silicon and quartz is 95°; manually adjust the position of the piston rod 2 until the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com