Method for synthesizing o-nitroacetophenone compound

A technology for nitroacetophenone and compound, applied in the field of organic compound synthesis, can solve problems such as psychological pressure, inconvenience in operation, toxicity of raw materials, etc., and achieve the effects of good substrate adaptability, simple reaction steps and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

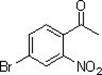

[0037] (1) Using acetophenone as raw material

[0038]

[0039] (2) Add 0.600 g (5.0 mmol) of acetophenone, 0.414 g (6.0 mmol) of hydroxylamine hydrochloride, 0.492 g (6.0 mmol) of anhydrous sodium acetate and 3 ml of methanol into a 25 ml flask. After the mixture was heated to reflux for 2 hours, TLC detected that the reaction was complete. After adding 15 ml of ethyl acetate for dilution, the solids in the mixed solution were dissolved with 2 N sodium hydroxide solution. The resulting mixed solution was extracted with ethyl acetate, dried and removed under reduced pressure. solvent to obtain 0.641 g (95% yield) of light yellow solid acetophenone oxime.

[0040] (3) The volume ratio of the obtained light yellow solid acetophenone oxime to DMSO:H 2 O = 1:1 solution was dissolved, 2.5 g potassium hydroxide (0.5 g × 5) and 0.852 g (6.0 mmol) methyl iodide were added, and stirred at room temperature for 3 hours. After the reaction was detected by TLC, the reaction solution w...

Embodiment 2

[0045] (1) Using 4-fluoroacetophenone as raw material

[0046]

[0047] (2) Add 0.690 g (5.0 mmol) of 4-fluoroacetophenone, 0.414 g (6.0 mmol) of hydroxylamine hydrochloride, 0.492 g (6.0 mmol) of anhydrous sodium acetate and 3 ml of methanol into a 25 ml flask. After the mixture was heated to reflux for 2 hours, TLC detected that the reaction was complete. After adding 15 ml of ethyl acetate for dilution, the solids in the mixed solution were dissolved with 2 N sodium hydroxide solution. The resulting mixed solution was extracted with ethyl acetate, dried and removed under reduced pressure. solvent to obtain 0.734 g (96% yield) of 4-fluoroacetophenone oxime as a pale yellow solid.

[0048] (3) The obtained light yellow solid 4-fluoroacetophenone oxime was mixed with the volume ratio DMSO:H 2 O = 1:1 solution was dissolved, 2.5 g potassium hydroxide (0.5 g × 5) and 0.852 g (6.0 mmol) methyl iodide were added, and stirred at room temperature for 3 hours. After the reaction...

Embodiment 3

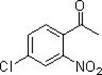

[0053] (1) Using 4-chloroacetophenone as raw material

[0054]

[0055] (2) Add 0.770 g (5.0 mmol) of 4-chloroacetophenone, 0.414 g (6.0 mmol) of hydroxylamine hydrochloride, 0.492 g (6.0 mmol) of anhydrous sodium acetate and 3 ml of methanol into a 25 ml flask. After the mixture was heated to reflux for 2 hours, TLC detected that the reaction was complete. After adding 15 ml of ethyl acetate for dilution, the solids in the mixed solution were dissolved with 2 N sodium hydroxide solution. The resulting mixed solution was extracted with ethyl acetate, dried and removed under reduced pressure. solvent to obtain 0.811 g (96% yield) of 4-chloroacetophenone oxime as a pale yellow solid.

[0056] (3) The obtained light yellow solid 4-chloroacetophenone oxime was mixed with DMSO:H 2 O = 1:1 solution was dissolved, 2.5 g potassium hydroxide (0.5 g × 5) and 0.852 g (6.0 mmol) methyl iodide were added, and stirred at room temperature for 3 hours. After the reaction was detected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com