Acrylate rubber turbine ascending pipe and preparation method thereof

A turbocharging and acrylic technology, applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of high hose costs, achieve the effects of convenient operation, simplified production process, and excellent pulse performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

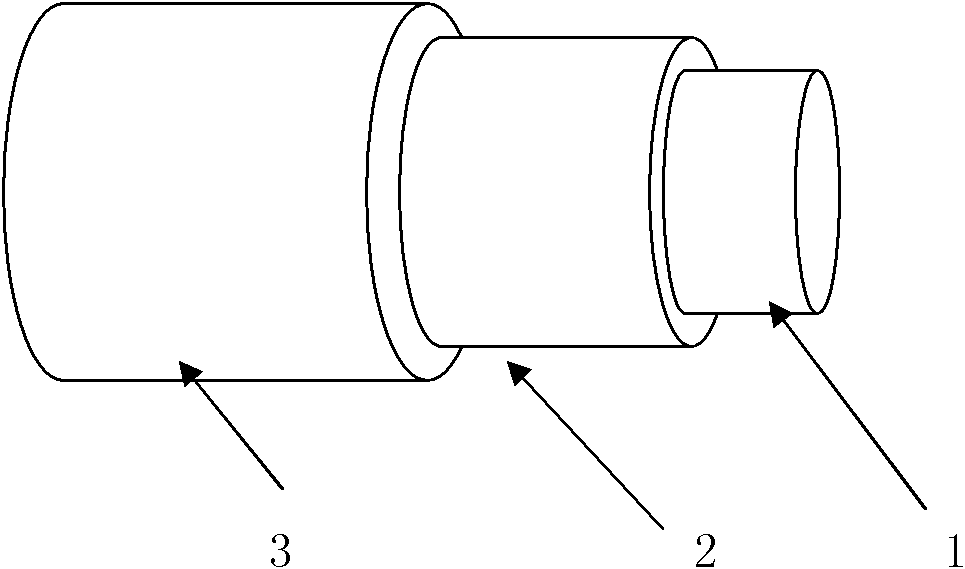

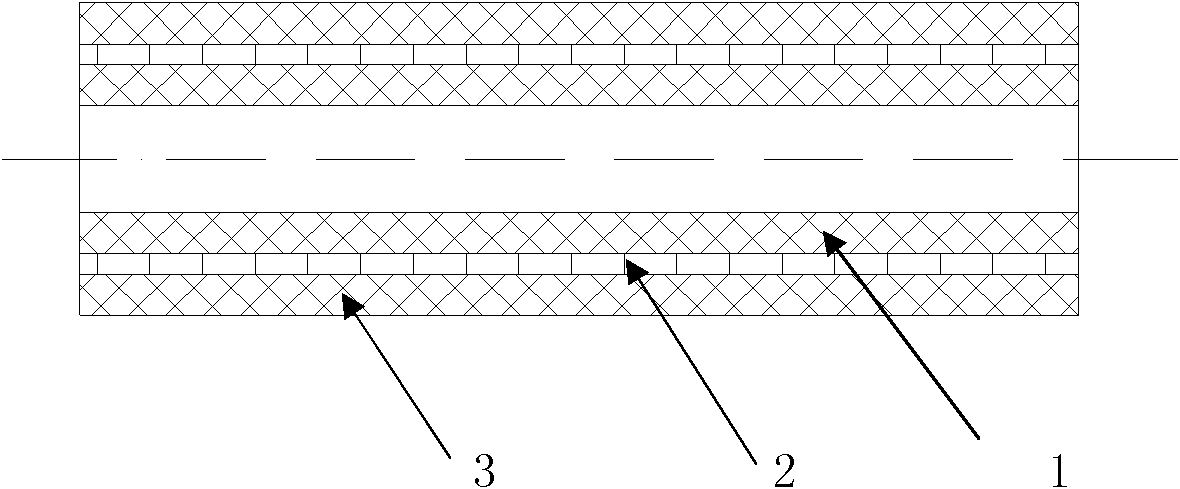

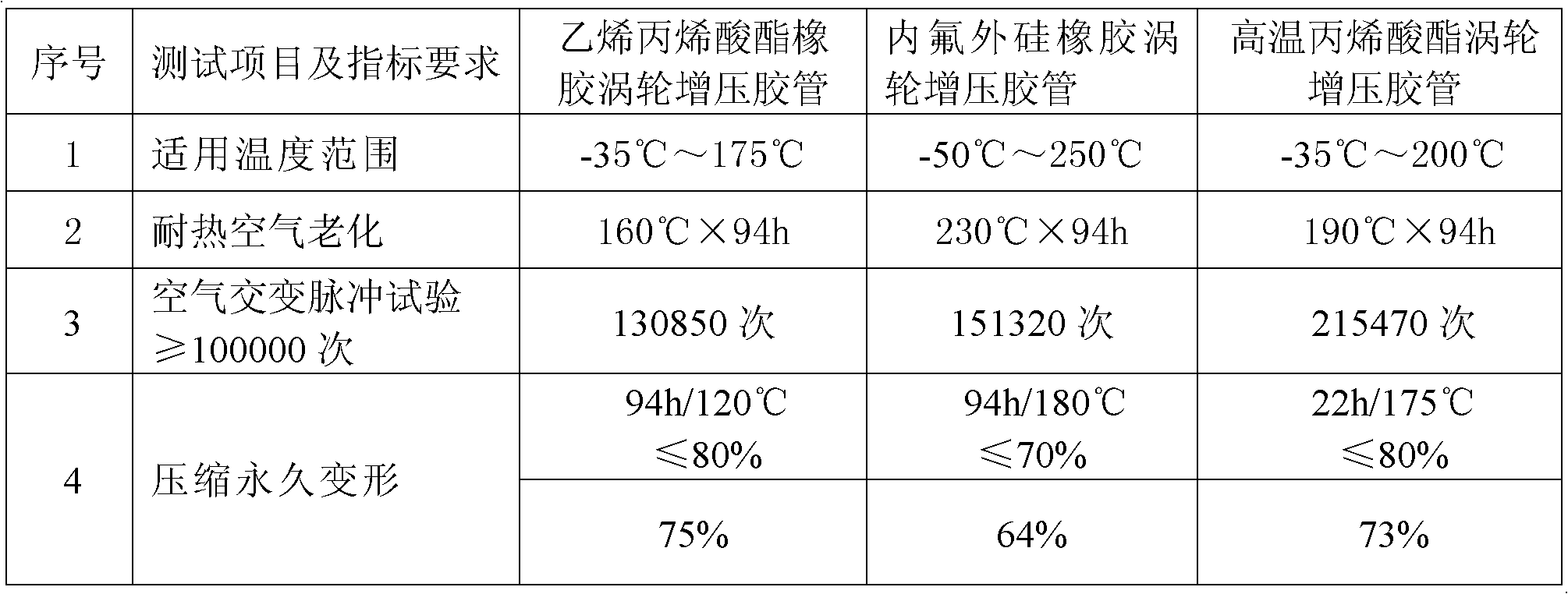

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] Statistics based on the mass fraction of each component:

[0021] components

Example 1

Example 2

Example 3

100

100

100

1

1.5

2

Quick Extrusion Carbon Black N550

50

60

70

Plasticizer TP759

5

10

15

Internal Mold Release Agent Vanfre VAM

0.5

0.8

1

Antiaging agent Naugard 445

1

1.5

2

Vulcanizing agent Diak 1# (1)

0.5

1

2

Accelerator DPG

0.5

2

3

[0022] Note: (1) Hexamethylenediamine formate, produced by DuPont

[0023] ① Prepare the mixed rubber according to the above examples 1, 2, and 3, and use the two-stage rubber refining process of the internal mixer to produce it to ensure that the rubber mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com