Catalyst for preparing styrene by dehydrogenizing ethylbenzene and preparation method thereof

A technology for ethylbenzene dehydrogenation and ethylbenzene dehydrogenation, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of insufficient mechanical strength and stability of catalysts To avoid problems such as decreased performance, achieve high activity and selectivity, high mechanical strength, and improve the effect of alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

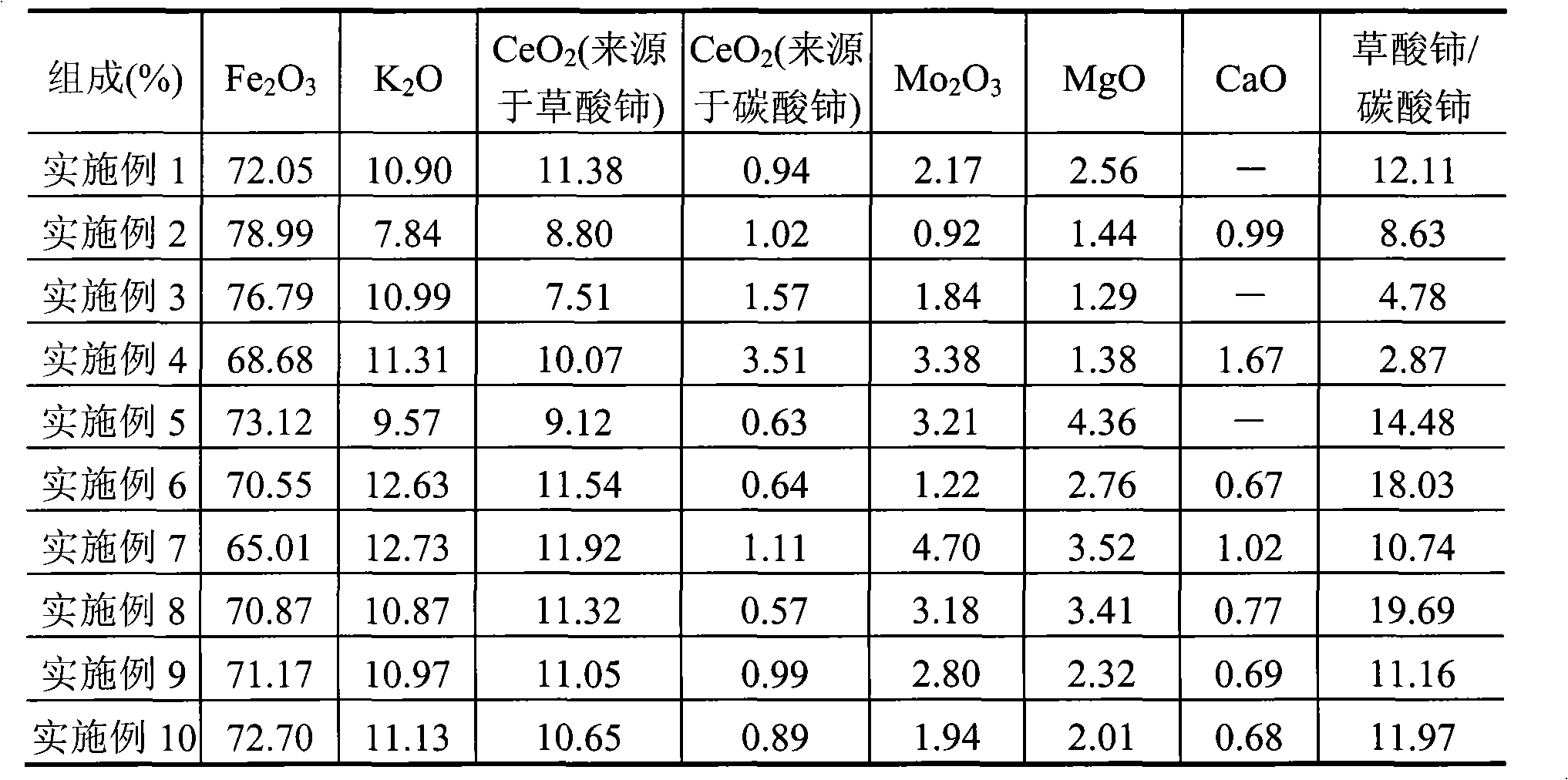

[0024] Put 212.0 grams of iron oxide red, 80.0 grams of iron oxide yellow, 60.0 grams of potassium carbonate, 88.0 grams of cerium oxalate, 7.2 grams of cerium carbonate, 10.0 grams of ammonium molybdate, 9.6 grams of magnesium oxide and 20.5 grams of carboxymethyl cellulose in a kneader Stir for 1 hour, add deionized water, stir for another half an hour, take out the extruded strips, extrude them into particles with a diameter of 3 mm and a length of 5 to 10 mm, put them in an oven, bake at 80°C for 2 hours, and at 120°C for 2 hours, then place In a muffle furnace, calcined at 850°C for 4 hours to obtain the finished catalyst.

[0025] The mechanical strength of the catalyst was measured, and the test results are listed in Table 1.

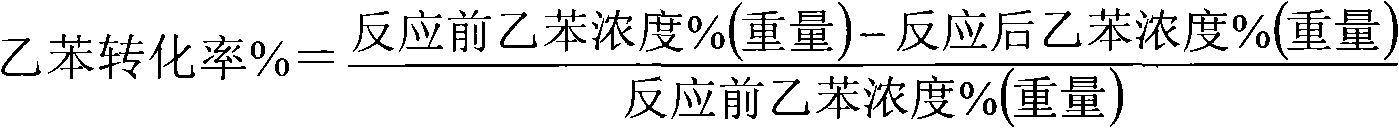

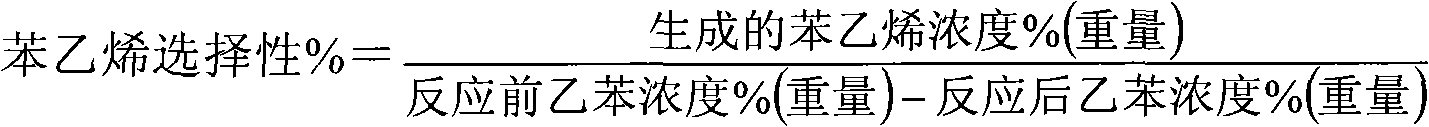

[0026] 100 milliliters of catalysts are loaded into the reactor, at normal pressure, liquid space velocity 1.0 hours -1 , 620°C, water vapor / ethylbenzene (weight ratio) 2.0 conditions for activity evaluation, the test results are listed in Table...

Embodiment 2

[0028] 210.0 grams of iron oxide red, 183.0 grams of iron oxide yellow, 52.0 grams of potassium carbonate, 82.0 grams of cerium oxalate, 9.5 grams of cerium carbonate, 5.1 grams of ammonium molybdate, 6.5 grams of magnesium oxide, 8.0 grams of calcium carbonate and 2.0 grams of polystyrene Balls, 16.5 grams of carboxymethyl cellulose were stirred in a kneader for 1 hour, added deionized water, and stirred for another half an hour, took out the extruded strips, extruded into granules with a diameter of 3 mm and a length of 5 to 10 mm, and put them into an oven at 120 ℃ for 2 hours, then placed in a muffle furnace, and calcined at 650 ℃ for 14 hours to obtain the finished catalyst.

[0029] Activity evaluation and mechanical strength determination were carried out according to the evaluation conditions of Example 1, and the test results are listed in Table 1.

Embodiment 3

[0031] 282.0 grams of iron oxide red, 103.5 grams of iron oxide yellow, 75.0 grams of potassium carbonate, 72.0 grams of cerium oxalate, 15.0 grams of cerium carbonate, 10.5 grams of ammonium molybdate, 6.0 grams of magnesium oxide, 7.0 grams of hydroxyethyl cellulose, 20.3 grams of carboxymethyl The base cellulose was stirred in a kneader for 1 hour, added deionized water, and stirred for another half an hour, took out the extruded strands, extruded into granules with a diameter of 3 mm and a length of 5 to 10 mm, put them in an oven, and baked them at 50 ° C for 12 hours, then Put it in a muffle furnace and bake it at 1000°C for 0.5 hour to obtain the finished catalyst.

[0032] Activity evaluation and mechanical strength determination were carried out according to the evaluation conditions of Example 1, and the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com