Casein active single peptide as well as preparation method and application thereof

A casein and bioactive peptide technology, applied in the field of bioactive single peptides that can promote yogurt fermentation and inhibit post-acidification of yogurt, can solve the problems of heavy sour taste, shortened shelf life, and affecting the quality of yogurt, so as to shorten the fermentation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Utilizing casein hydrolyzate to produce a biologically active single peptide that significantly promotes yogurt fermentation and inhibits post-acidification of yogurt

[0027] 1. Controllable enzymolysis: Add papain to enzymolyze casein under the conditions of 50°C and pH 6.0 to obtain an enzymolysis solution.

[0028] 2. Enzyme inactivation with enzymatic hydrolysis solution: heat at 90°C for 15 minutes to inactivate the enzyme and terminate the enzymatic hydrolysis reaction.

[0029] 3. Centrifuge the enzyme-inactivated hydrolyzate (6000 x g, 4°C) for 20 minutes, and ultrafilter the supernatant (take the

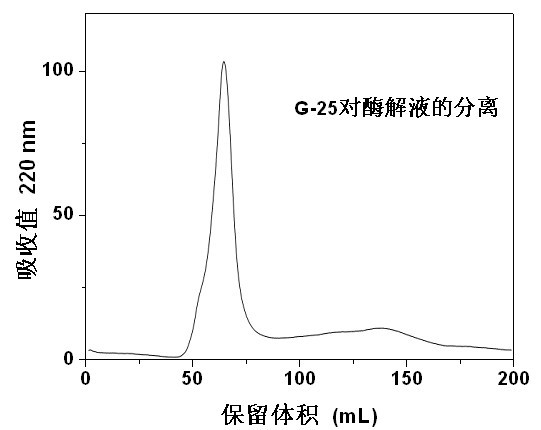

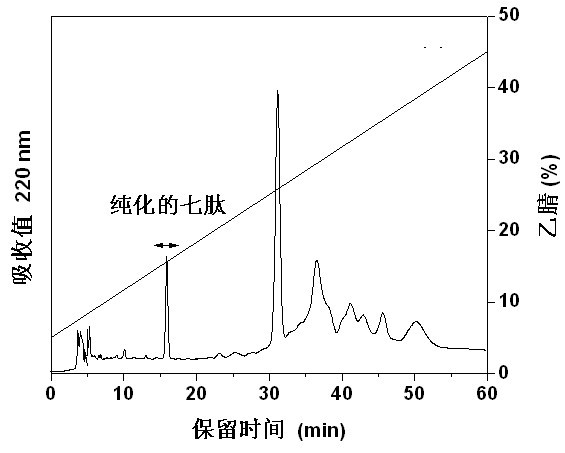

[0030] After 3000 Dalton components), the macroporous resin NKA-II was used to collect the 10% (w / w) ethanol eluate, followed by Sephadex G-25, the mobile phase was deionized water, and the detection wavelength was 220nm. Collected in order of absorption peaks, such as figure 1 shown. The components with strong activity separated by Sephadex G-25 were...

Embodiment 2

[0032] Example 2: Utilizing casein hydrolyzate to produce biologically active single peptides that can significantly promote yogurt fermentation and inhibit post-acidification of yogurt

[0033] 1. Controllable enzymatic hydrolysis: Add papain to enzymolyze casein under the conditions of 55°C and pH 7.5 to obtain an enzymatic hydrolysis solution.

[0034] 2. Enzyme hydrolysis solution inactivation: heat at 95°C for 20 minutes to inactivate the enzyme and terminate the enzymatic hydrolysis reaction.

[0035] 3. Centrifuge the enzyme-inactivated hydrolyzate (6000 x g, 4°C) for 20 minutes, and ultrafilter the supernatant (take the

[0036] After 3000 Dalton components), the macroporous resin NKA-II was used to collect 20% (w / w) ethanol eluate, followed by Sephadex G-25, the mobile phase was deionized water, and the detection wavelength was 220nm. Collected in order of absorption peaks, such as figure 1 shown. The components with strong activity separated by Sephadex G-25 were...

Embodiment 3

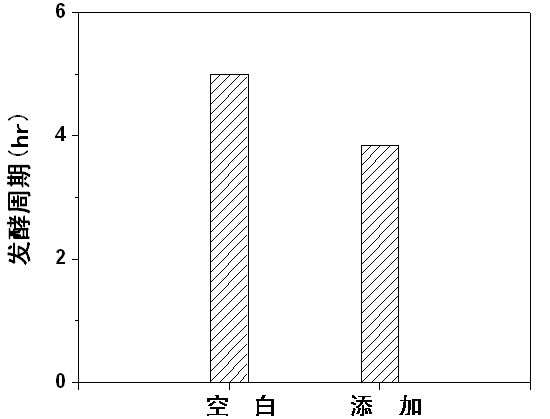

[0038] Example 3: Effects of bioactive peptides on the fermentation cycle of yoghurt

[0039] Before yogurt fermentation, add 50ppm (w / w) of the bioactive peptide HAQQKE obtained in Example 1 to replace milk powder with equal protein, and measure the yogurt fermentation cycle, namely T pH4.5 , the time required for yogurt to ferment to pH4.5, in hours. Such as image 3 As shown, the yoghurt fermentation period was shortened by 23.00% after adding NPSKENL.

[0040] Example 3: Effects of Bioactive Peptides on Changes in Acidity of Yogurt During Storage Period

[0041] Measure according to the titration acidity of the fermented yoghurt of embodiment 2 during 28 days of storage, i.e. the degree of cleanliness T 0 Variety.

[0042] Test method: Use a 5ml straw to take 5ml of fermented milk that has been stirred evenly, add it to a conical flask containing 25ml of distilled water, add 3 to 4 drops of 1% phenolphthalein indicator, and titrate with 0.1NNaOH to light red, and kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com