High-voltage pulse electric field sterilizing treatment chamber for monitoring strength and temperature of electric fields on line

A technology of high-voltage pulsed electric field and electric field strength, applied in thermometers, thermometers with electrical/magnetic components directly sensitive to heat, electromagnetic field characteristics, etc., can solve temperature rise, measurement flow characteristics, reliability and accuracy doubts, etc problem, to avoid the problem of error compensation, strong anti-interference ability, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

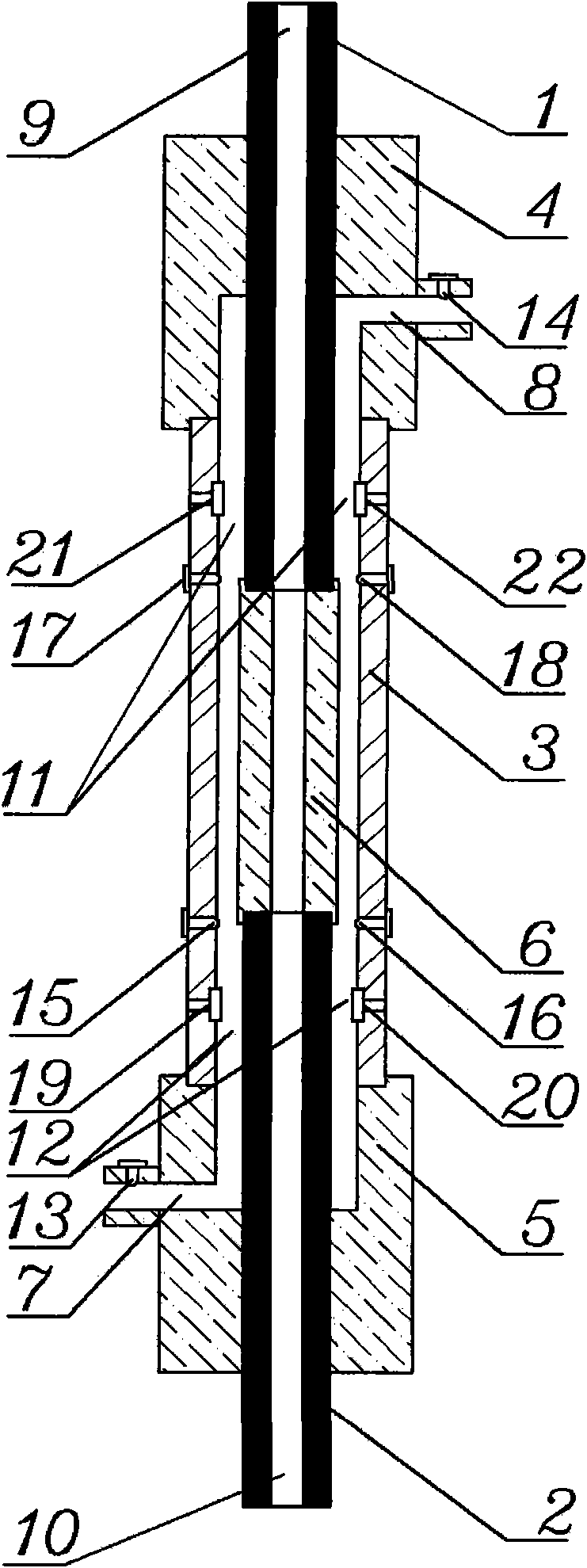

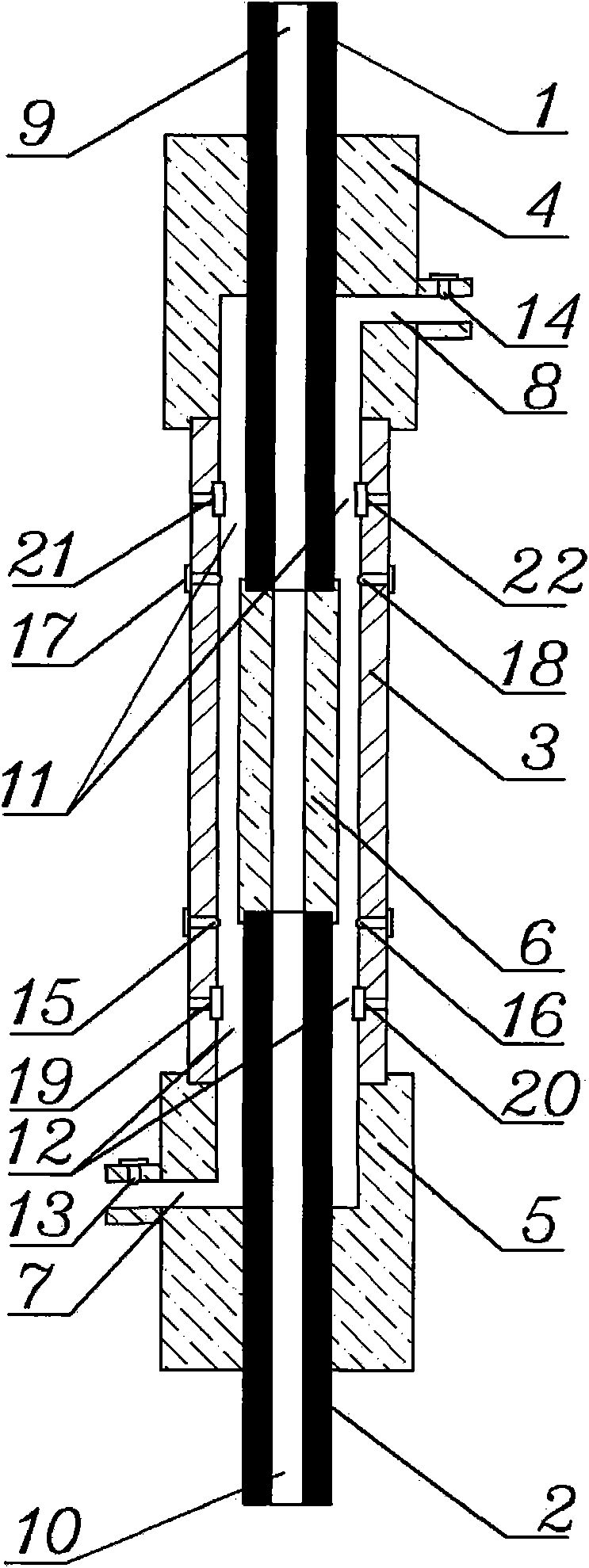

[0021] In the coaxial continuous high-voltage pulsed electric field sterilization treatment chamber involved in the present invention, one end of the tubular grounding electrode 3 with an inner diameter of 26 mm and an outer diameter of 36 mm is installed on one end of the first insulating protective sheath 4, and the other end of the tubular grounding electrode 3 is One end is installed on one end of the second insulating protective cover 5, the first insulating protective cover 4 has a material outlet 8 in the radial direction, and the second insulating protective cover 5 has a material inlet 7 in the radial direction; coaxially installed in the tubular grounding electrode 3 One end of an insulating tube 6 with an inner diameter of 6 mm and an outer diameter of 18 mm is connected to one end of a first tubular high-voltage electrode 1 with an inner diameter of 6 mm and an outer diameter of 16 mm, and the other end of the first tubular high-voltage electrode 1 extends out of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com