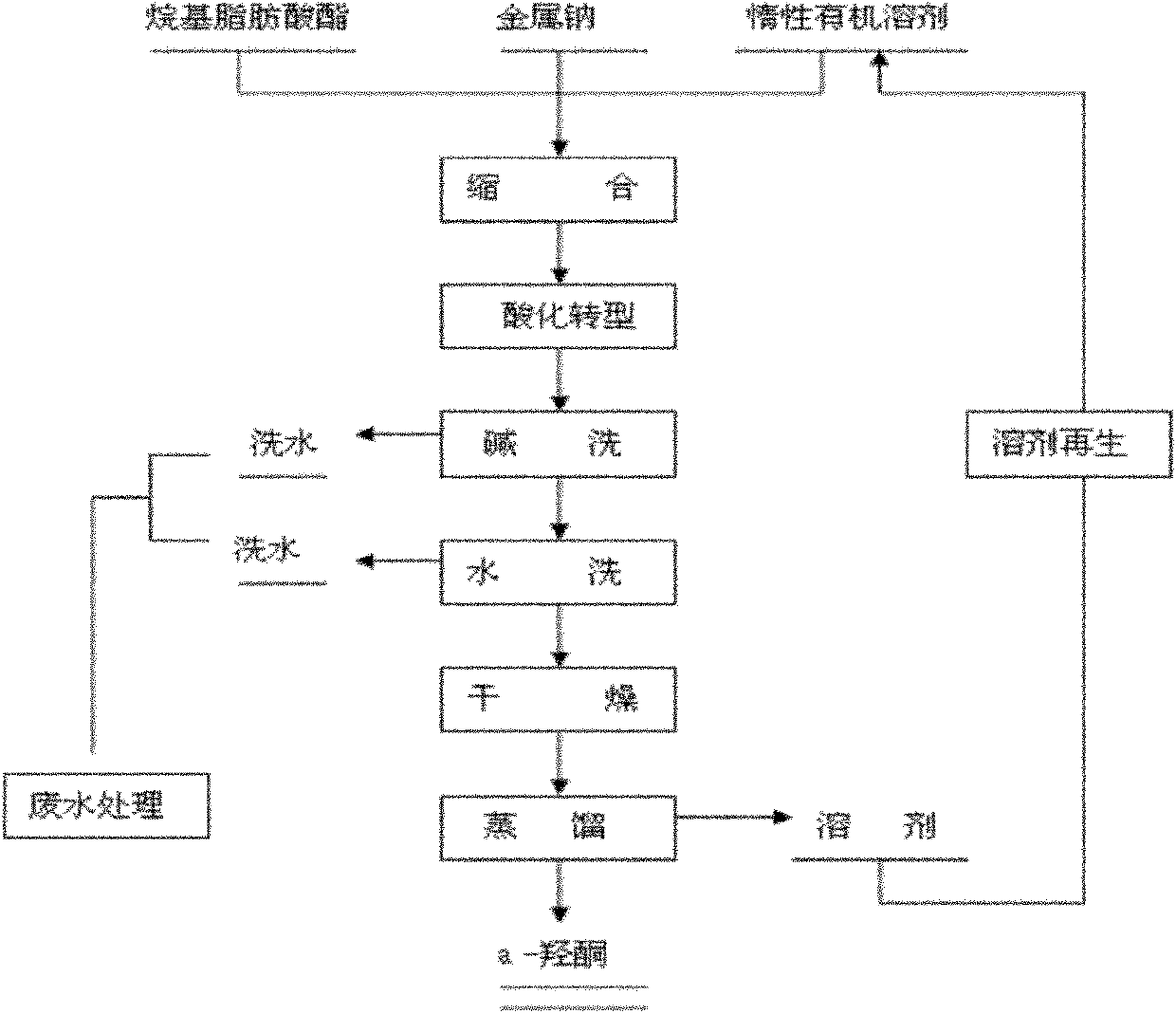

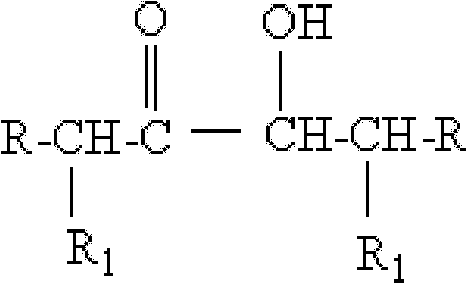

Preparation method of alpha-hydroxyl ketone compounds

A compound and hydroxyketone technology, applied in the preparation of organic compounds, carbon-based compounds, chemical instruments and methods, etc., can solve problems such as difficult to realize industrial production, and achieve stable product quality, short reaction time and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

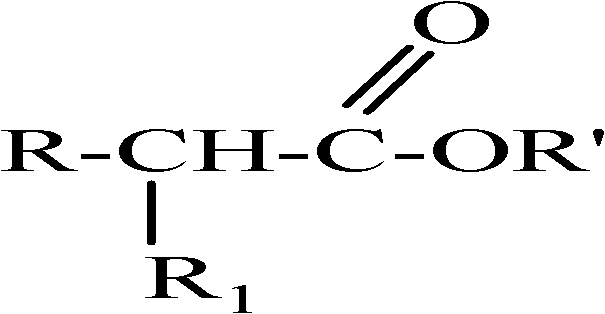

Method used

Image

Examples

Embodiment 1

[0030]Example 1: In a four-necked 1-liter reactor equipped with a stirrer, reflux condenser, dropping funnel, and temperature sensor, add 300ml of toluene, then add 15.8g of sodium metal to remove surface oxides, heat up and heat until the sodium melts , start stirring until the sodium turns into fine particles, and the rotating speed is 750 rpm; when the temperature of the mixture in the reactor reaches 107°C, maintain the temperature, and add dropwise a mixture of 200ml of toluene and 50ml of methyl isooctanoate under stirring. After the dropwise addition, the reaction mixture changed from blue-yellow to brown-yellow, and the reaction mixture became thicker. Control the dropping speed, and drop feed liquid within 2 hours. After stirring and keeping warm for 0.5 hour, the reacted mixture was cooled to room temperature, and unreacted metal sodium pieces were taken out. Slow first and then fast, carefully control the dropwise addition of 150ml of sulfuric acid with a concentra...

experiment example 2

[0031] Experimental Example 2: In a four-necked 1-liter reactor equipped with a stirrer, reflux condenser, dropping funnel, and temperature sensor, add 300ml of xylene, then add 16.8g of sodium metal that removes surface oxides, and heat up to sodium Melt, start stirring until the sodium turns into fine particles, the rotation speed is 750 rpm; when the temperature of the mixture in the reactor reaches 105°C, maintain the temperature, and add dropwise the mixture consisting of 200ml xylene and 50ml ethyl octanoate while stirring. After the dropwise addition, the reaction mixture changed from blue-yellow to brown-yellow, and the reaction mixture became thicker. Control the dropping speed, and drop feed liquid within 2 hours. After stirring and keeping warm for 1 hour, the reacted mixture was cooled to room temperature, and unreacted metal sodium pieces were taken out. Slow first and then fast, carefully control the dropwise addition of 160ml hydrochloric acid for transformatio...

experiment example 3

[0032] Experimental Example 3: In a four-necked 1-liter reactor equipped with a stirrer, reflux condenser, dropping funnel, and temperature sensor, add 300ml of toluene, then add 14.8g of metallic sodium to remove surface oxides, heat up and heat until the sodium melts , start stirring until the sodium turns into fine particles, and the rotation speed is 750 rpm; when the temperature of the mixture in the reactor reaches 110°C, maintain the temperature, and add dropwise a mixture of 200ml toluene and 50ml methyl stearate under stirring. After the dropwise addition, the reaction mixture changed from blue-yellow to brown-yellow, and the reaction mixture became thicker. Control the dropping speed, and drop feed liquid within 2 hours. After stirring and keeping warm for half an hour, the reacted mixture was cooled to room temperature, and unreacted metal sodium pieces were taken out. Slow first and then fast, carefully control the dropwise addition of 160ml of nitric acid for tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com