Electrochemical CF (Carbon Fiber) surface modification method

A surface modification and electrochemical technology, applied in chemical instruments and methods, fiber treatment, anodic oxidation, etc., can solve the problem of poor microbial fixation effect and achieve the effect of improving microbial fixation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

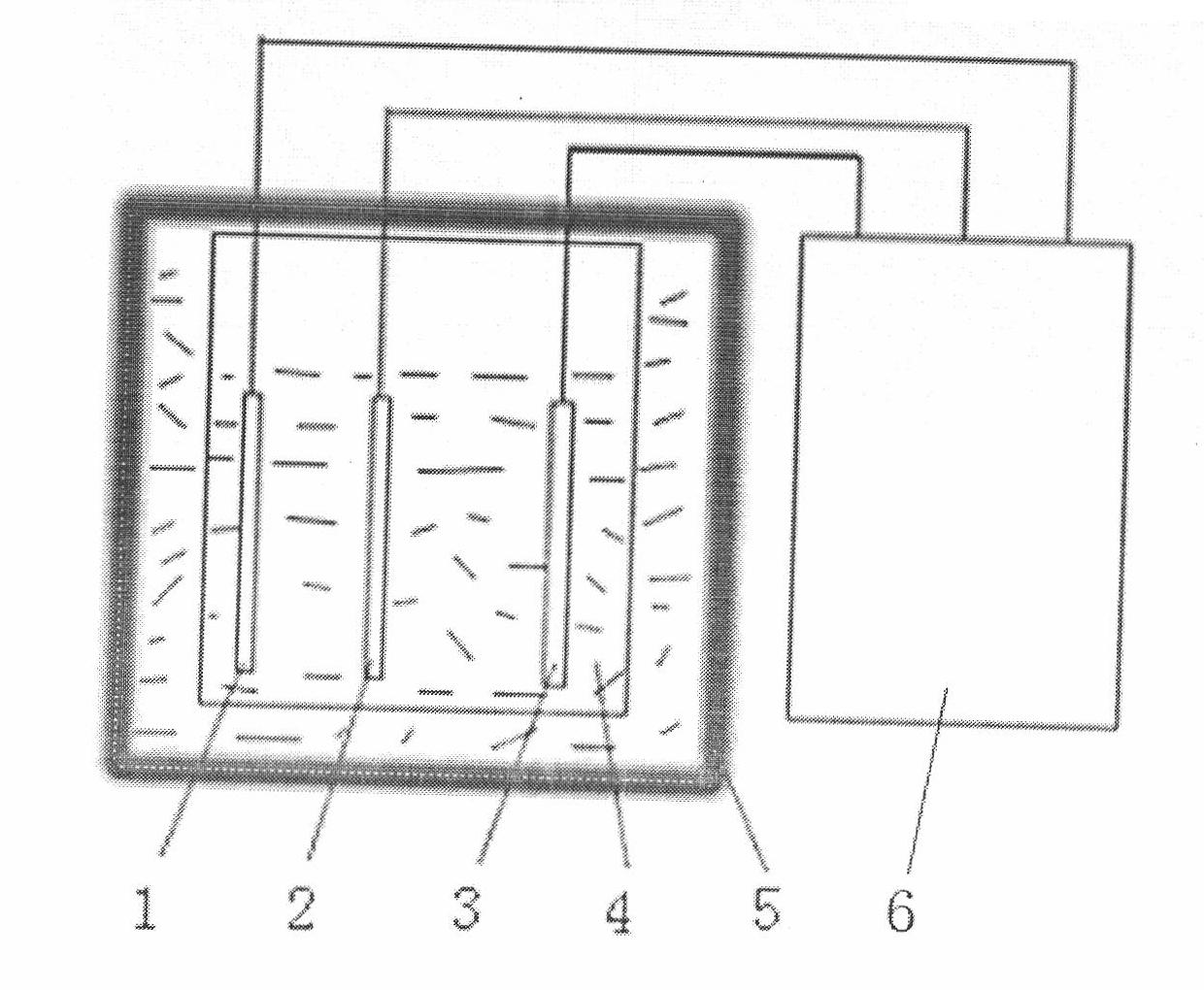

Image

Examples

Embodiment 1

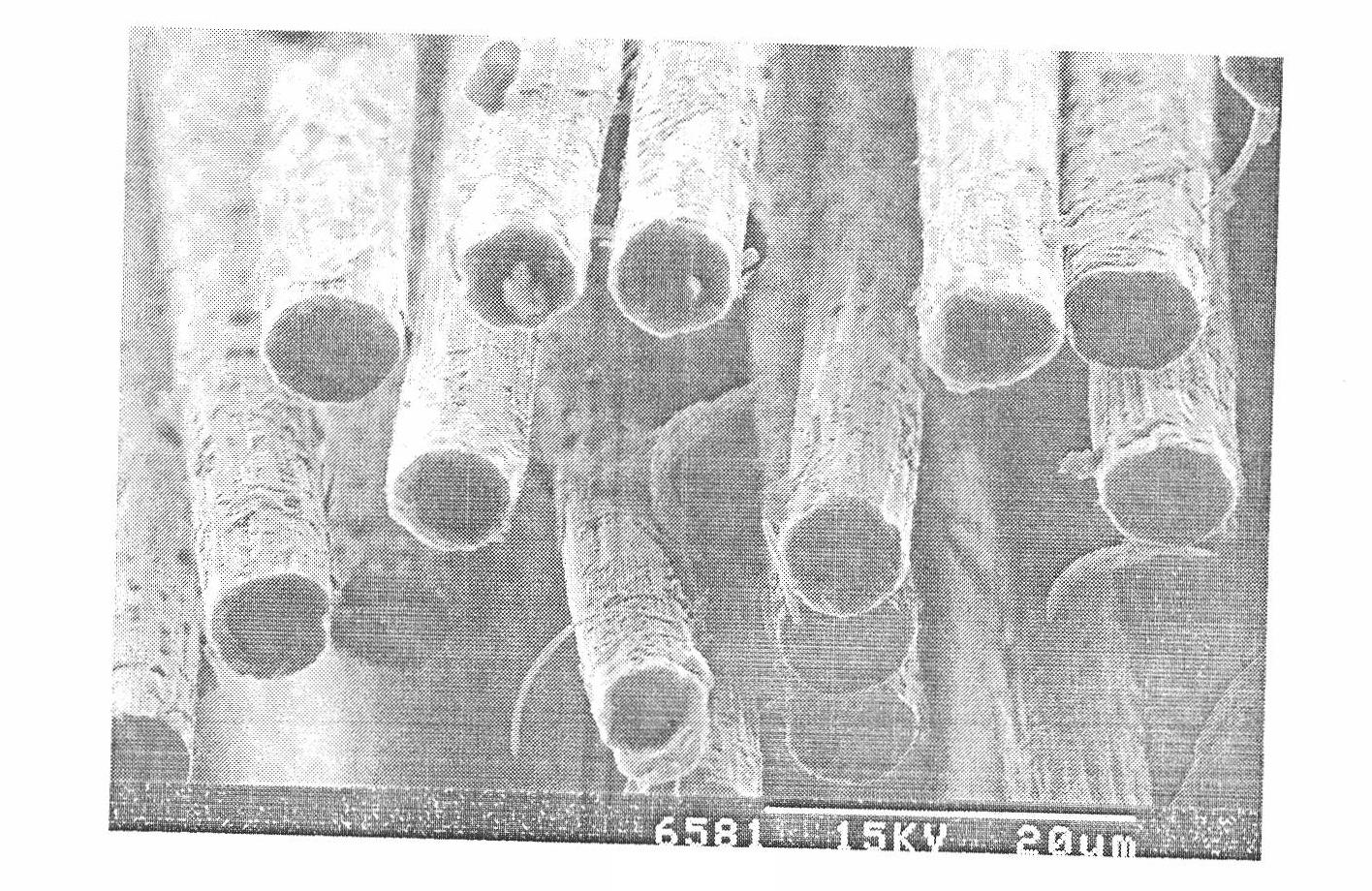

[0016] Remove the surface sizing agent from the high-strength polyacrylonitrile-based carbon fiber (PAN-CF, T300) at room temperature, rinse with distilled water and dry; then use CF as the anode, graphite as the cathode, platinum electrode as the auxiliary electrode, and saturated calomel The electrode is a reference electrode, and CF is anodized by chronoamperometry. 0.1-1mol / L nitric acid solution is used as the electrolyte, the applied voltage is 0.5-1.5V, the reaction temperature is 20-27°C, and the reaction time is 120-150s. The surface treatment results are as follows: the total amount of oxygen-containing functional groups on the surface is 40.84%, the equilibrium water content is 5.88%, and the biofilm fixation amount is 135%. Its SEM photos are as figure 2 shown.

Embodiment 2

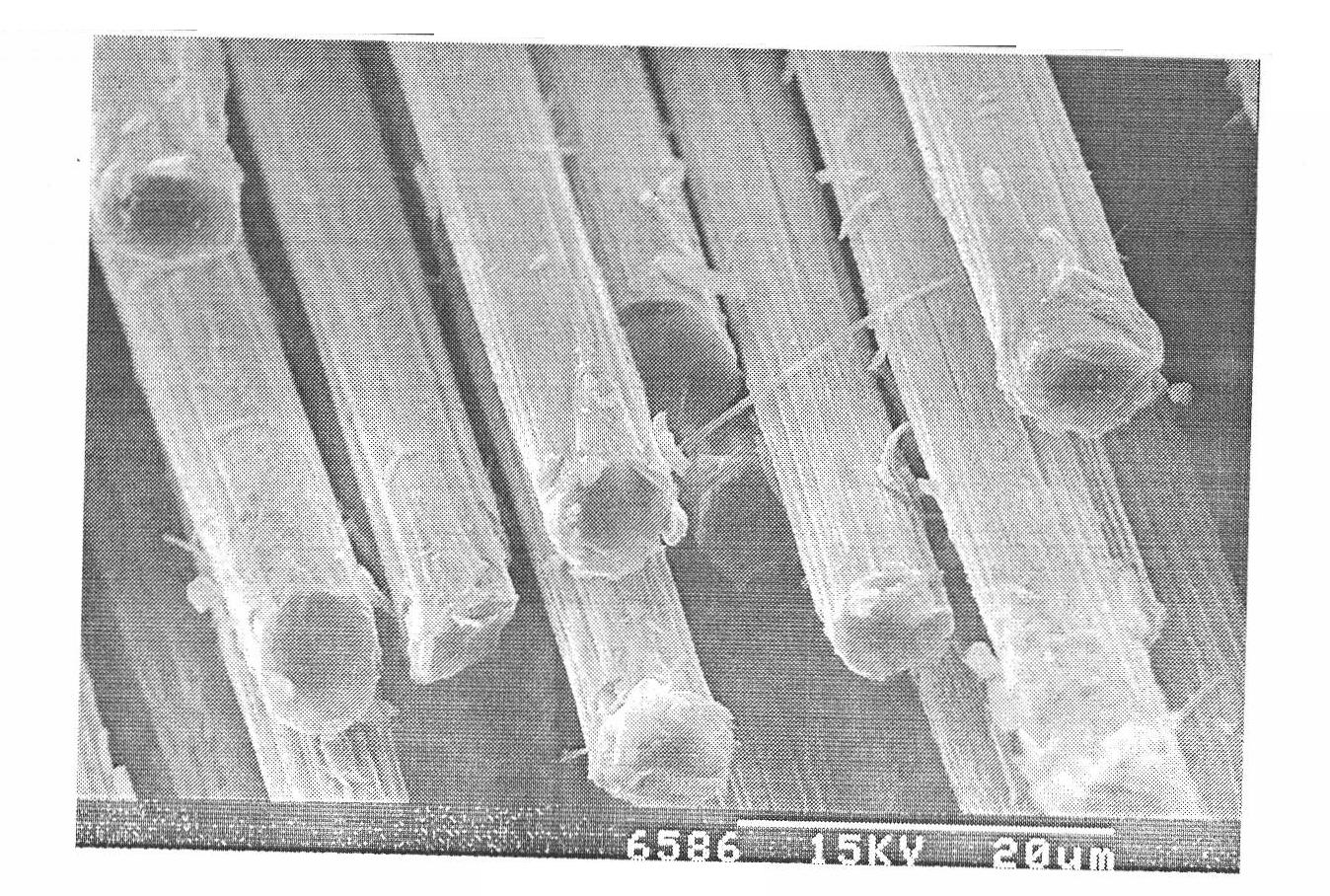

[0018] Remove the surface sizing agent from the high-strength polyacrylonitrile-based carbon fiber (PAN-CF, T300) at room temperature, rinse with distilled water and dry; then use CF as the anode, graphite as the cathode, platinum electrode as the auxiliary electrode, and saturated calomel The electrode is a reference electrode, and the surface electropolymerization of CF is carried out by chronoamperometry. 0.1-0.5mol / L maleic anhydride is used as the elemental solution, the applied voltage is 1-2V, the reaction temperature is 25-30°C, and the reaction time is 100-130s. The surface treatment results are as follows: the total amount of oxygen-containing functional groups on the surface is 36.82%, the equilibrium moisture content is 5.69%, and the biofilm fixation amount is 212%. Its SEM photos are as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com