Technology for producing CBN (Cubic Boron Nitride) high-speed ceramics grinding wheel

A ceramic and grinding wheel technology, which is applied in the manufacture of tools, metal processing equipment, grinding/polishing equipment, etc., can solve problems affecting the cutting efficiency of grinding wheels, and achieve the effects of improving wrapping capacity, reducing costs, and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

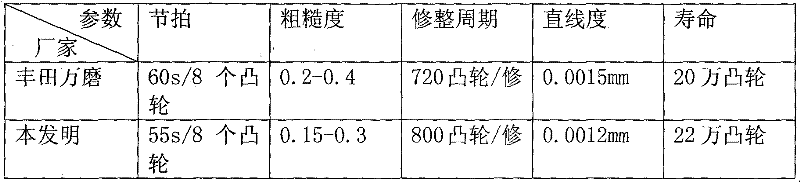

Image

Examples

Embodiment 1

[0024] 1. Preparation of binder

[0025] 1. Pre-melted ceramic powder

[0026] a. Mixing of raw materials: mix the raw materials according to the following parts ratio (volume ratio), boric anhydride 20, lepidolite 35, albite feldspar 40, Na 2 CO 3 5;

[0027] b. High temperature firing: 1600 degrees (Celsius);

[0028] c. Water cooled to room temperature;

[0029] d. Broken and passed through 240 standard sieves;

[0030] e. The powder under the sieve is dried, and the obtained powder is pre-melted ceramic powder.

[0031] 2. Binder mixing

[0032] Nanoscale AL 2 o 3 Powder, nano-mullite powder, and pre-melted ceramic powder are mixed evenly by ball milling at a mass ratio of 2:3:5, and the resulting product is a binder

[0033] 2. Preparation of ceramic abrasive layer

[0034] a. Weigh the abrasive layer according to the following proportions (volume ratio): 35% of bonding agent, 8% of white corundum, 7% of aluminum oxide hollow ball, and 50% of CBN;

[0035] b. T...

Embodiment 2

[0040] 1. Preparation of binder

[0041] 1. Pre-melted ceramic powder

[0042] a. Mixing of raw materials: mix the raw materials according to the following parts ratio (volume ratio), boric anhydride 15, lepidolite 45, albite 30, Na 2 CO 3 10;

[0043] b. High temperature firing: 1600 degrees (Celsius);

[0044] c. Water cooled to room temperature;

[0045] d. Broken and passed through 240 standard sieves;

[0046] e. The powder under the sieve is dried, and the obtained powder is pre-melted ceramic powder.

[0047] 2. Binder mixing

[0048] Nanoscale AL 2 o 3 Powder, nano-mullite powder, and pre-melted ceramic powder are mixed evenly by ball milling at a mass ratio of 2:3:5, and the resulting product is a binder

[0049] 2. Preparation of ceramic abrasive layer

[0050] a. Weigh the abrasive layer according to the following proportions (volume ratio): 35% of bonding agent, 8% of white corundum, 7% of aluminum oxide hollow ball, and 50% of CBN;

[0051] b. Take the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com