Preparation method for (meth)acrylate

A technology of acrylate and acrylic acid, applied in the field of preparation of acrylate, can solve the problems of reducing process efficiency, shortening life and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

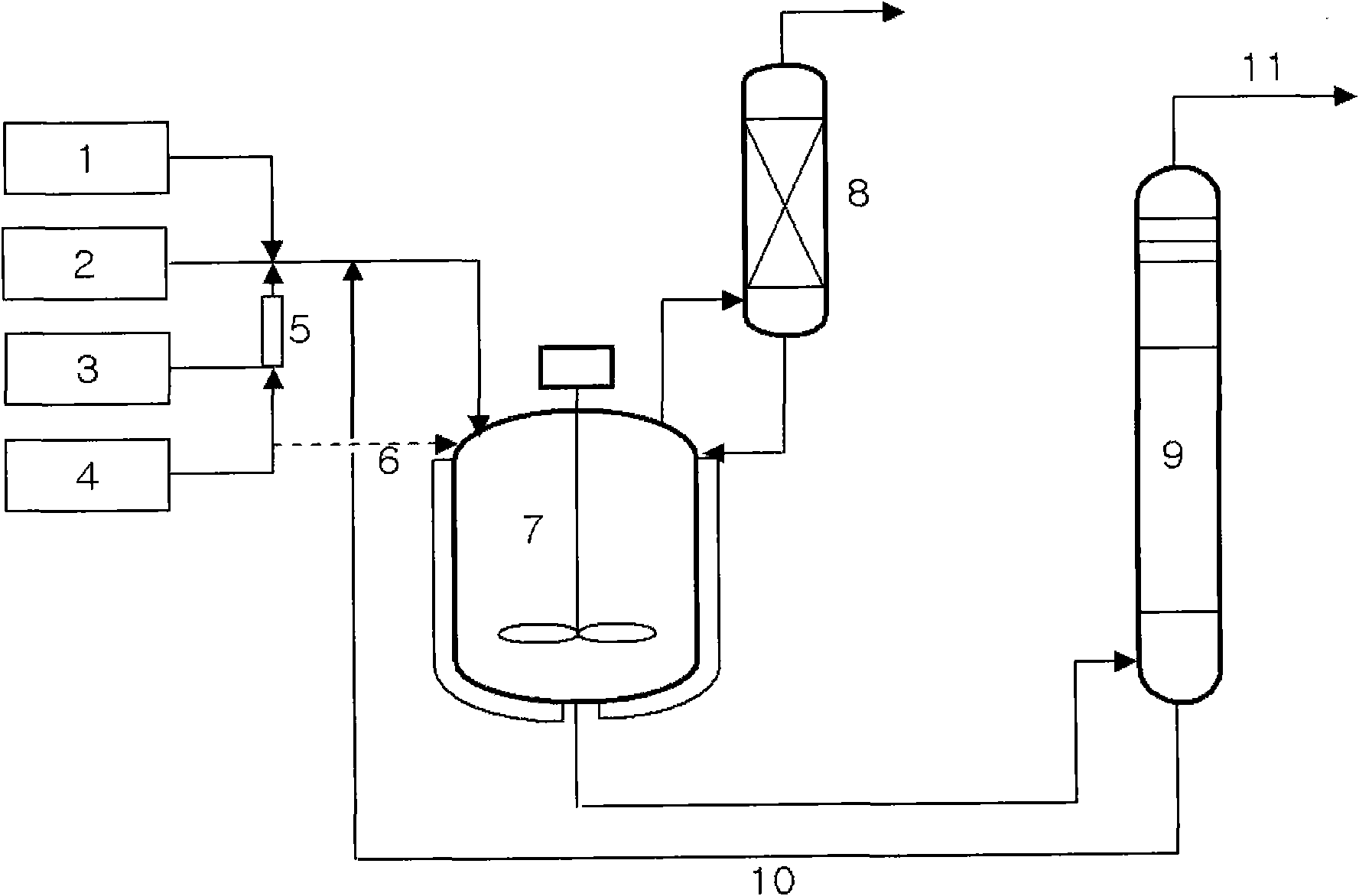

[0041] The preparation method of the (meth)acrylate may be in a batch mode or a continuous mode, and a continuous mode is preferred.

[0042] In the present invention, if impurities are generated, they will remain in the (meth)acrylic acid production equipment and reduce the production efficiency. The production equipment containing residual impurities refers to the bottom or pipeline of the reactor and the refiner.

[0043] In the present invention, the catalyst is preferably one or more selected from the following: inorganic acids, such as sulfuric acid, hydrochloric acid, phosphoric acid and nitric acid; organic acids containing sulfonic acid groups, such as methanesulfonic acid, p-toluenesulfonate Acid (pTSA) and alkyl sulfuric acid; natural / synthetic zeolite, cation and anion exchange resins; metal salts such as lithium fluoride, potassium chloride, cesium chloride, calcium chloride, iron chloride and aluminum phosphate; metal oxides , Such as heteropoly acid; and organometall...

Embodiment 1

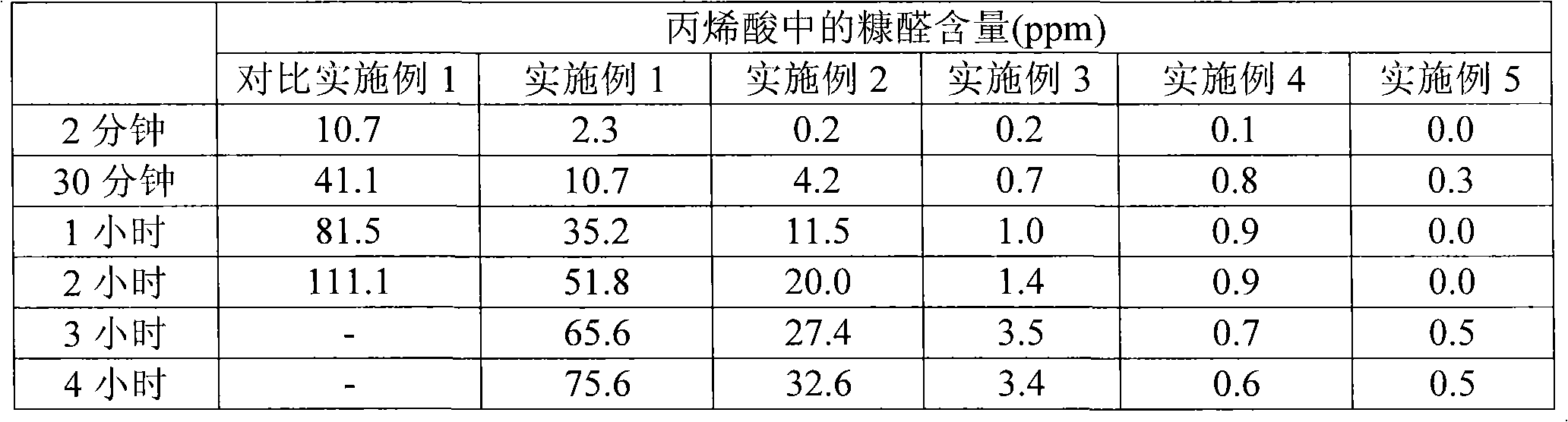

[0051] The evaluation was performed in the same manner as in Comparative Example 1, except that hydrazine hydrate was added at a molar ratio of 2 to the total amount of furfural. The results are shown in Table 1 below.

Embodiment 2

[0053] The evaluation was performed in the same manner as in Comparative Example 1, except that hydrazine hydrate was added at a molar ratio of 3 to the total amount of furfural. The results are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com