Method for emulsification continuous feeding of heavy oil weight catalytic cracking raw material

A catalytic cracking raw material, heavy technology, applied in the direction of catalytic cracking, cracking, petroleum industry, etc., can solve the problems of high stability of emulsified raw materials, failure to improve product distribution, storage time can not be too long, etc., to improve fog The effect of improving the efficiency, improving the degree of dispersion and atomization, and reducing the coke yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

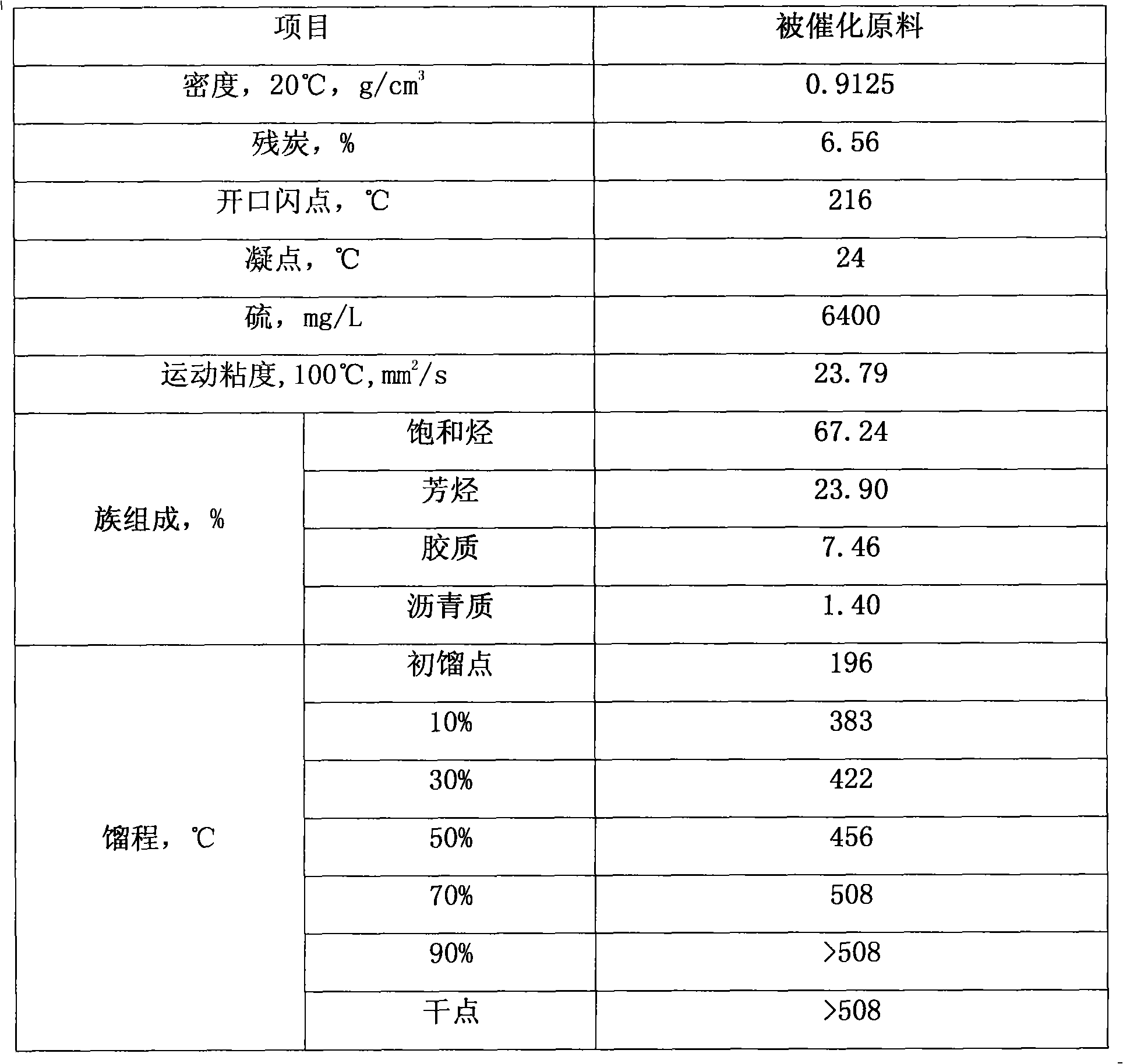

[0015] The raw material oil used in the emulsification test is the FCC raw material of a refinery, and its property analysis is shown in Table 1.

[0016] Table 1 Raw material properties

[0017]

[0018] The emulsifier used in the emulsification test is a nonionic-nonionic composite emulsifier. It is composed of emulsifier and metal deactivator. The emulsifier is composed of Tween 80, triethanolamine and light aromatic hydrocarbons below C9. The mass ratio is 50:40:10. Sales of metal passivator, emulsifier and passivator mixing ratio of 20:80. The physical and chemical properties of the compound emulsifier are shown in Table 2.

[0019] Table 2 Physicochemical properties of compound emulsifier

[0020] project

complex emulsifier

Exterior

yellow transparent liquid

Dissolved in water

[0021] Density (20℃), g / cm 3

1.00~1.15

Kinematic viscosity(50℃)mm 2 / s

18~25

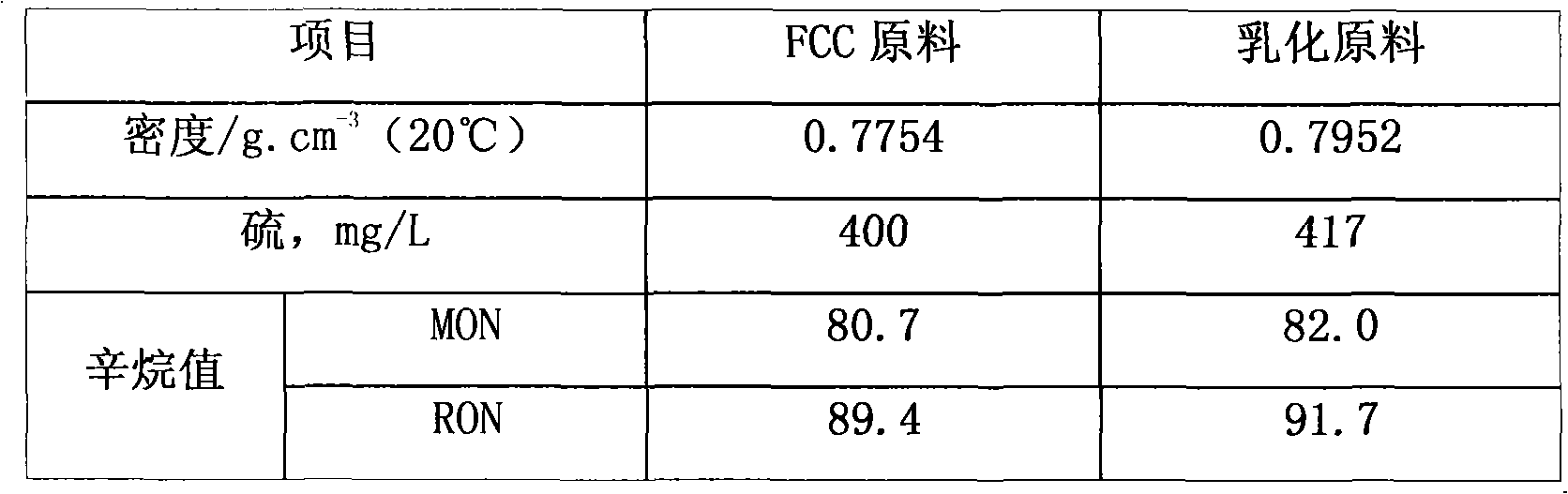

[0022] The FCC raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com