Method for making green tea wine

A production method and technology for green tea wine, which are applied in the preparation of alcoholic beverages and other directions, can solve the problems of insufficient aroma, high cost, and reduced alcohol yield, and achieve the effects of improving extraction efficiency, short production cycle and efficient extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

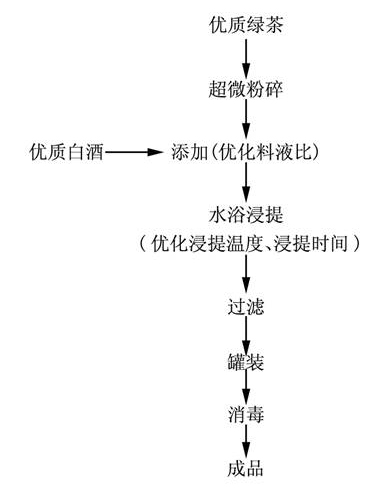

Method used

Image

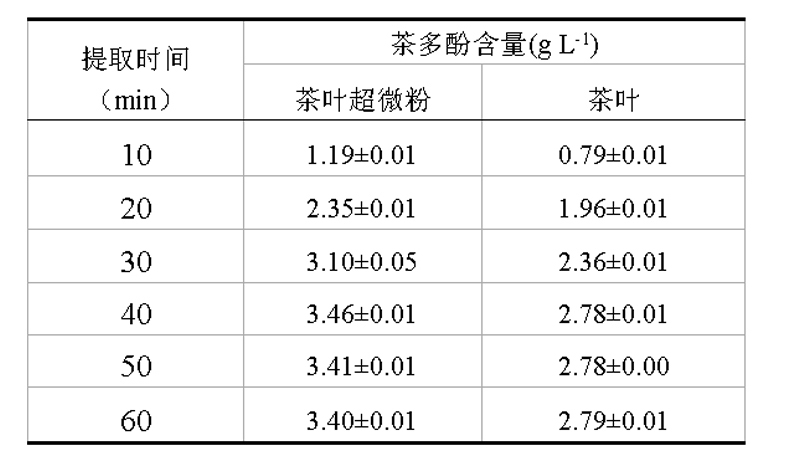

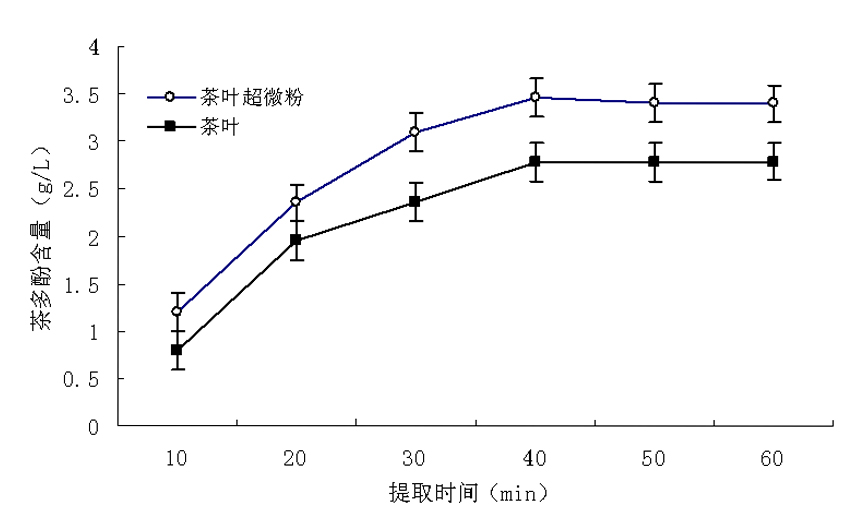

Examples

Embodiment 1

[0026] Using high-quality Lu'an Guapian tea as raw material, the production method of Lu'an Guapian tea is as follows:

[0027] The fresh tea leaves are made of high-quality Guapian tea according to the six processes of raw pot, cooked pot, rough fire, low fire, old fire and finishing. 1. Raw pot: pot temperature 100°C-120°C, stir-fry appropriate amount of tea leaves for 2 minutes; 2. Cooked pot: cooked pot temperature 70°C-80°C, adjust the shape, fry while patting, forming flaky young leaves with light force, The old leaf is hard. It takes about 5 minutes; 3. Gross fire: Baking with charcoal fire, the young leaves are spread thinly, and the old leaves are slightly thicker. And spread it to cool for about 10 hours; 4. Small fire: the top baking temperature is about 100°C-120°C, and it is required to turn it frequently; Turn the cage down, and turn it over 80 times while baking in turn; 6. Finishing: use a 12-mesh sieve to sieve the final tea, and the sieved surface tea is im...

Embodiment 2

[0034] Using high-quality Huangshan Maofeng as raw material, the production method of Huangshan Maofeng tea is as follows:

[0035] The fresh tea leaves are made of high-quality Huangshan Maofeng according to the three processes of greening, rolling and baking. 1. Finishing: The diameter of the pot is 50cm, the temperature of the pot is controlled at about 150-130°C, the amount of leaves thrown into each pot is 500g, and stir-fry 50-60 times per minute. After the fresh leaves are put into the pot, the sound of fried sesame seeds is the temperature. Moderate; 2. Kneading: After finishing the pot, dissipate the heat in time, gently knead for 1-2 minutes, so that it can be slightly curled into strips; 3. Baking: divided into initial baking and foot baking. In the initial drying, each green pot is equipped with four drying cages. The fire temperature is high first and then low, and the temperature of the top of the oven is above 90°C. After that, the temperature is lowered in turn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com