Method for producing acid xylanase from whey powder

A technology of acid xylanase and whey powder, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve the problem of low enzyme activity, and achieve simple production process, fast breeding of strains, high activity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

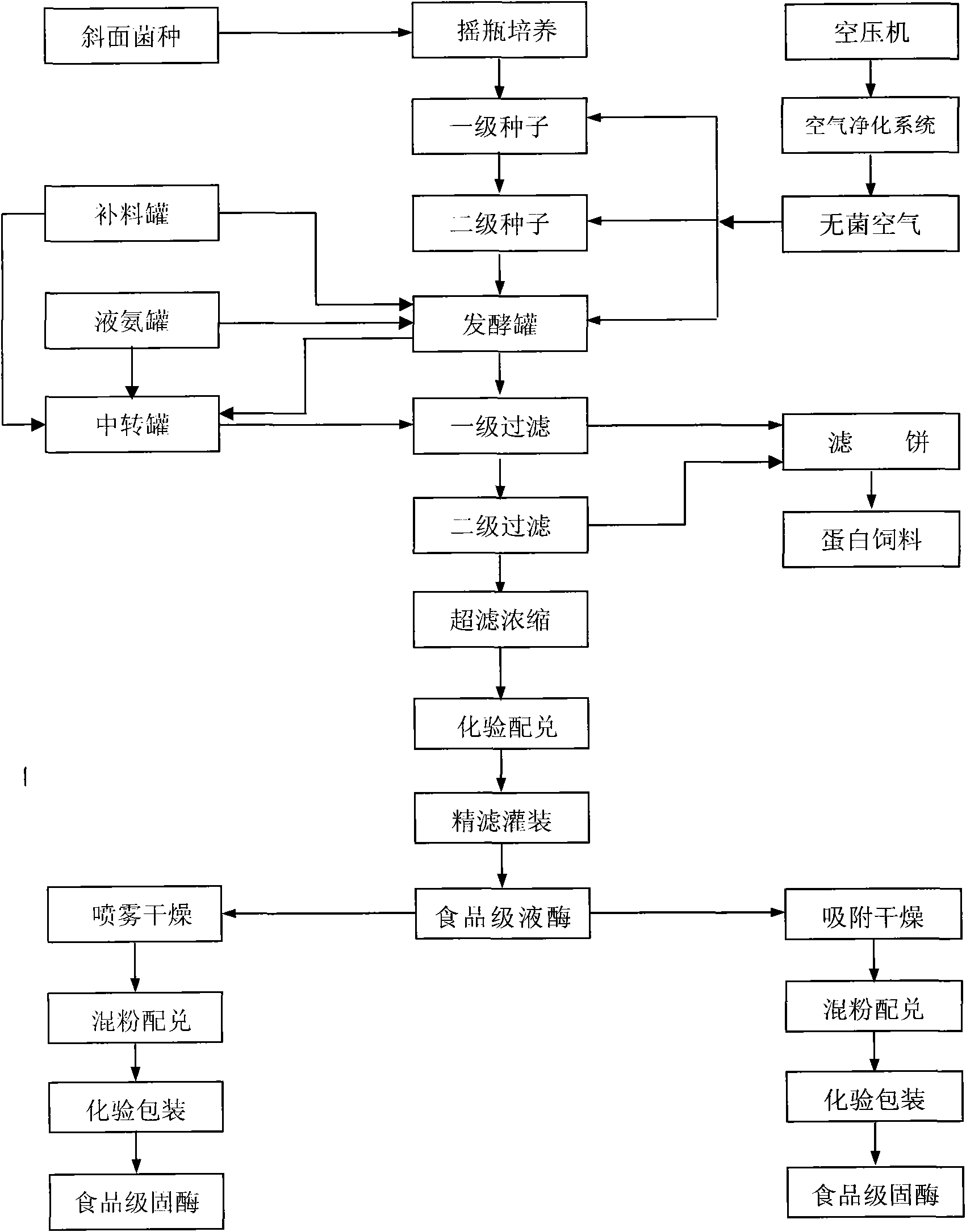

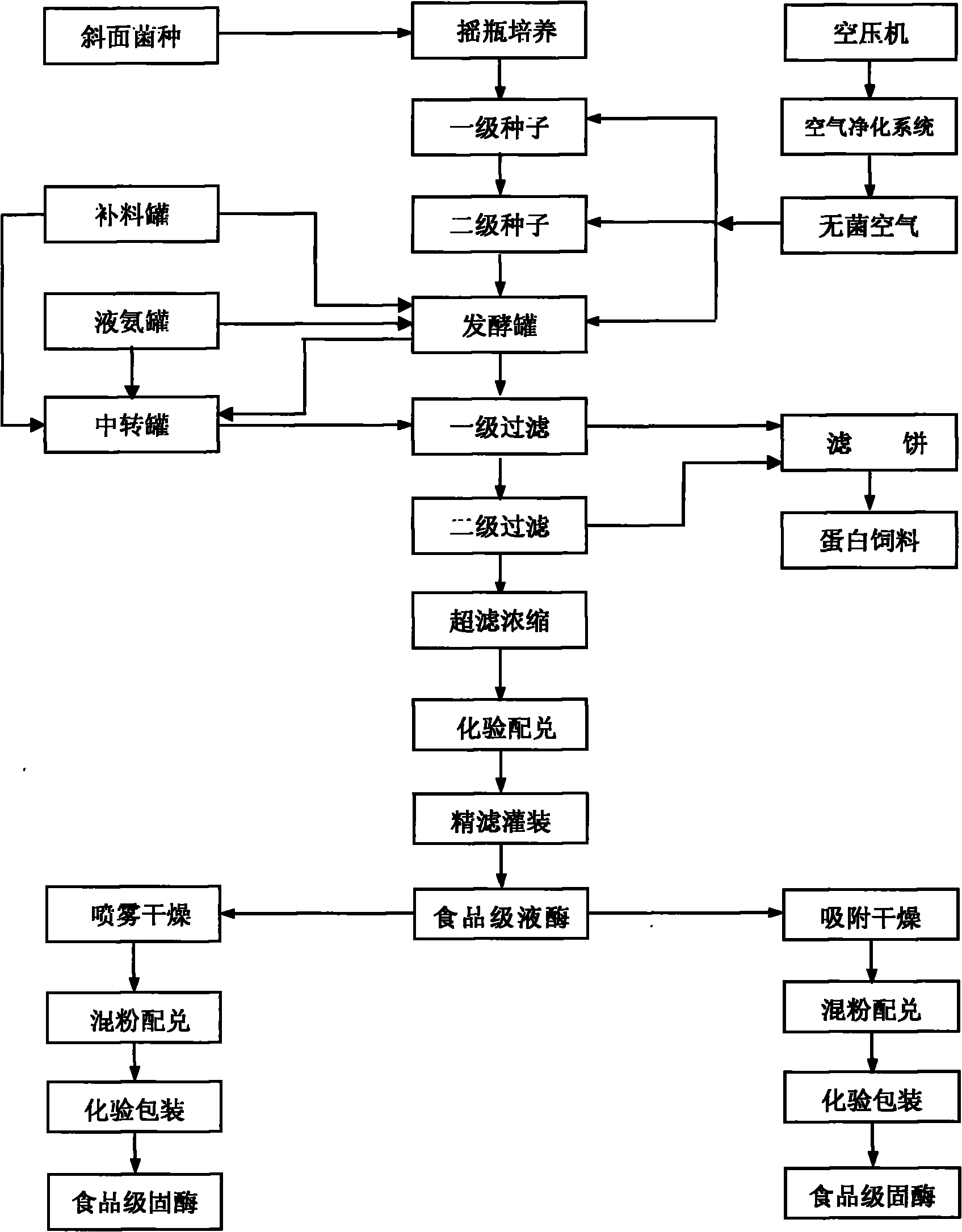

[0037] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

[0038] 1. Bacteria culture:

[0039] (1) Strain selection: In the production of acid xylanase, Trichoderma reesei provided by Shandong Food Fermentation Industry Research and Design Institute was selected as the starting strain, and potato culture medium was used to make slanted seeds for future use.

[0040] (2) Seed mother shake flask culture: put 300ml of seed mother medium into a 1000ml Erlenmeyer flask, cool to room temperature after sterilization, insert a ring of slanted seeds, place on a shaking table at a speed of 220-250r / min, and cultivate at a temperature of 28 Incubate at ±1°C for 30±2 hours.

[0041] 2. Production seed culture:

[0042] (1) Primary seed cultivation:

[0043] 1. In 1M 3 The amount of seed culture medium added to the stainless steel seed tank accounted for 70-75% of the tank volume, steam sterilized at 121°C, tank pressure 0.1-0.12M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com