Phosphorous ion-free treating agent for treating steel plate

A technology of phosphorus ions and steel plates, applied in the coating process of metal materials, etc., can solve problems such as health and environmental hazards, and achieve the effects of improved uniformity, excellent corrosion resistance, and good matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

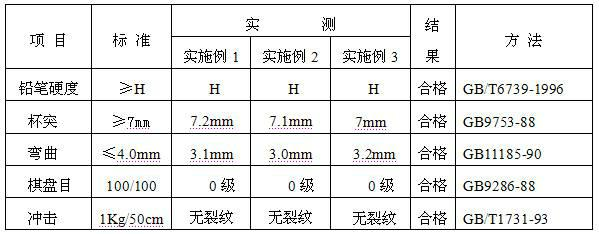

Examples

Embodiment 1

[0023] (1) A phosphorus-free ion forming agent for steel plate treatment

[0024] 1) Composition of the inorganic phase

[0025] Fluorozirconic acid 8%, Fluotitanic acid 4%,

[0026] Magnesium nitrate 3%, Aluminum nitrate 2%,

[0027] Ferric nitrate 0.2%, ammonium nitrate 0.2%,

[0028] n-butyl titanate 0.3%, hexamethylenetetramine 0.02%,

[0029] Water 82.28%;

[0030] Preparation method: according to the above ratio, put water, fluozirconic acid and fluotitanic acid in a container, add magnesium nitrate, iron nitrate, aluminum nitrate and ammonium nitrate in turn under stirring, and add hexamethylenetetramine after stirring evenly Stir with n-butyl titanate evenly;

[0031] 2) Composition of the organic phase

[0032] 3-Aminopropyltriethoxysilane 22%, Ethanolamine 12%,

[0033] Nonylphenol ethoxylate 7%, water 59%.

[0034] Preparation method: According to the above ratio, put water and nonylphenol polyoxyethylene ether in a container, and add them in sequence under ...

Embodiment 2

[0040] (1) A phosphorus-free ion forming agent for steel plate treatment

[0041] 1) Composition of the inorganic phase

[0042] Fluorozirconic acid 13%, Fluorotitanic acid 6%,

[0043] Magnesium nitrate 2.5%, Aluminum nitrate 1.8%,

[0044] Ferric nitrate 0.4%, ammonium nitrate 0.5%,

[0045] n-butyl titanate 0.4%, hexamethylenetetramine 0.05%,

[0046] Water 75.35%;

[0047] Preparation method: according to the above ratio, put water, fluozirconic acid and fluotitanic acid in a container, add magnesium nitrate, iron nitrate, aluminum nitrate and ammonium nitrate in turn under stirring, and add hexamethylenetetramine after stirring evenly Stir with n-butyl titanate evenly;

[0048] 2) Composition of the organic phase

[0049] N-2-Aminoethyl-3-aminopropyltrimethoxysilane 25%, Ethanolamine 20%,

[0050] Nonylphenol polyoxyethylene ether 8%, water 47%;

[0051] Preparation method: According to the above ratio, put water and nonylphenol polyoxyethylene ether in a containe...

Embodiment 3

[0057] (2) A phosphorus-free ion forming agent for steel plate treatment

[0058] 1) Composition of the inorganic phase

[0059] Fluorozirconic acid 20%, Fluotitanic acid 10%,

[0060] Magnesium nitrate 3.5%, Aluminum nitrate 2.2%,

[0061] Ferric nitrate 0.7%, ammonium nitrate 0.8%,

[0062] n-butyl titanate 0.6%, hexamethylenetetramine 0.45%,

[0063] Water 61.75%;

[0064] Preparation method: according to the above ratio, put water, fluozirconic acid and fluotitanic acid in a container, add magnesium nitrate, iron nitrate, aluminum nitrate and ammonium nitrate in turn under stirring, and add hexamethylenetetramine after stirring evenly Stir with n-butyl titanate evenly;

[0065] 2) Composition of the organic phase

[0066] Bis(3-trimethoxysilylpropyl)amine 20%, Ethanolamine 18%,

[0067] Nonylphenol polyoxyethylene ether 6%, water 56%;

[0068] Preparation method: according to the above ratio, put water and nonylphenol polyoxyethylene ether in a container, add bis(3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com