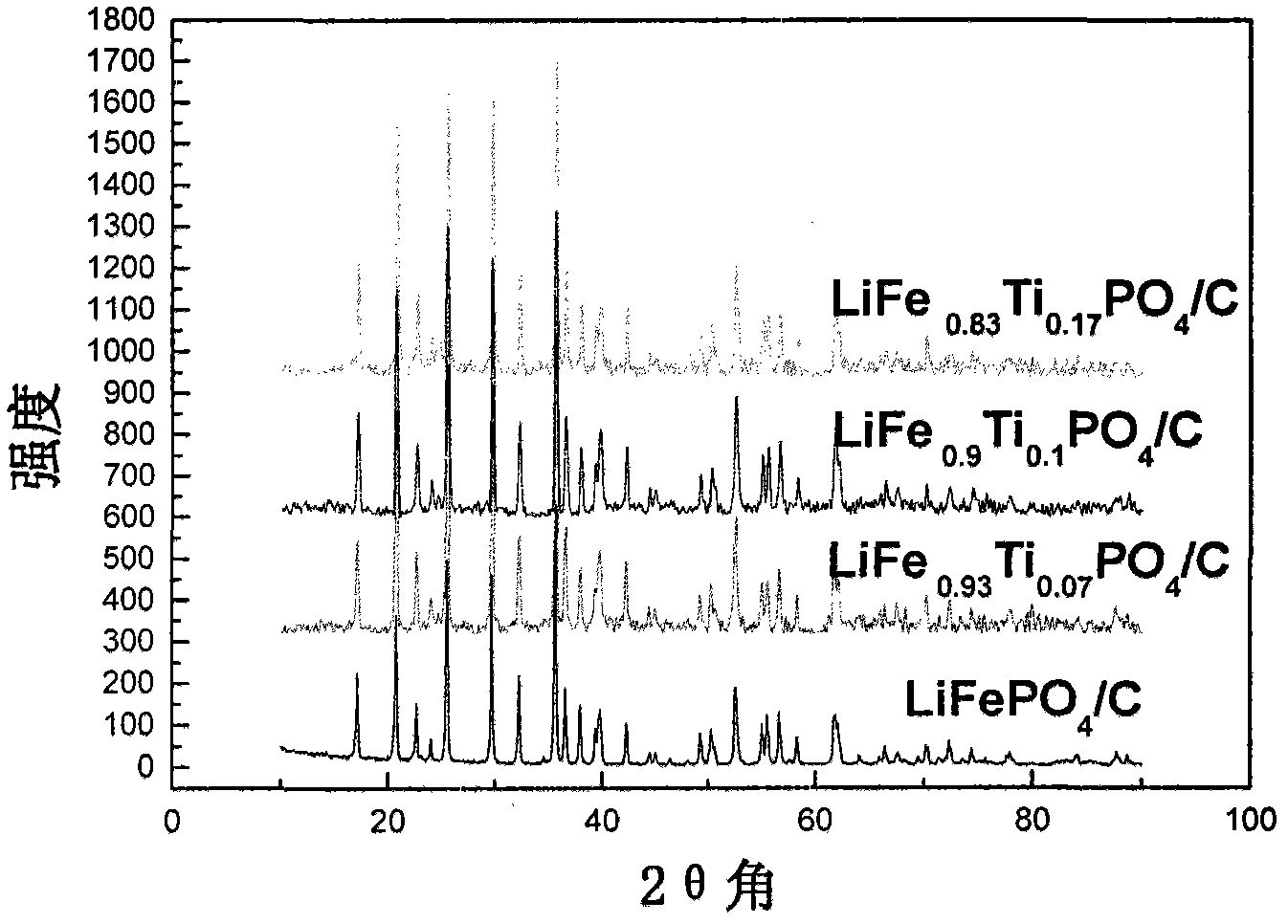

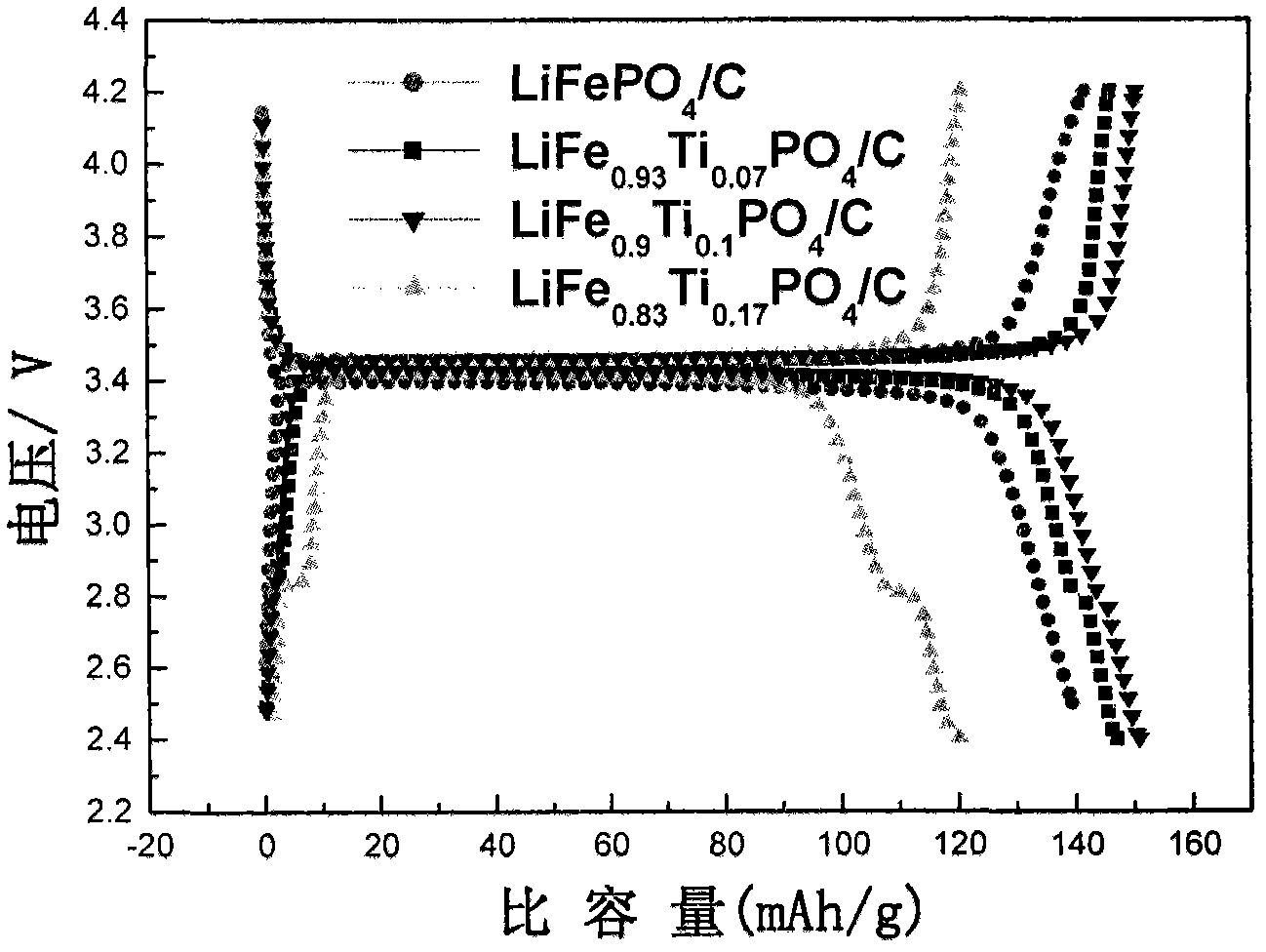

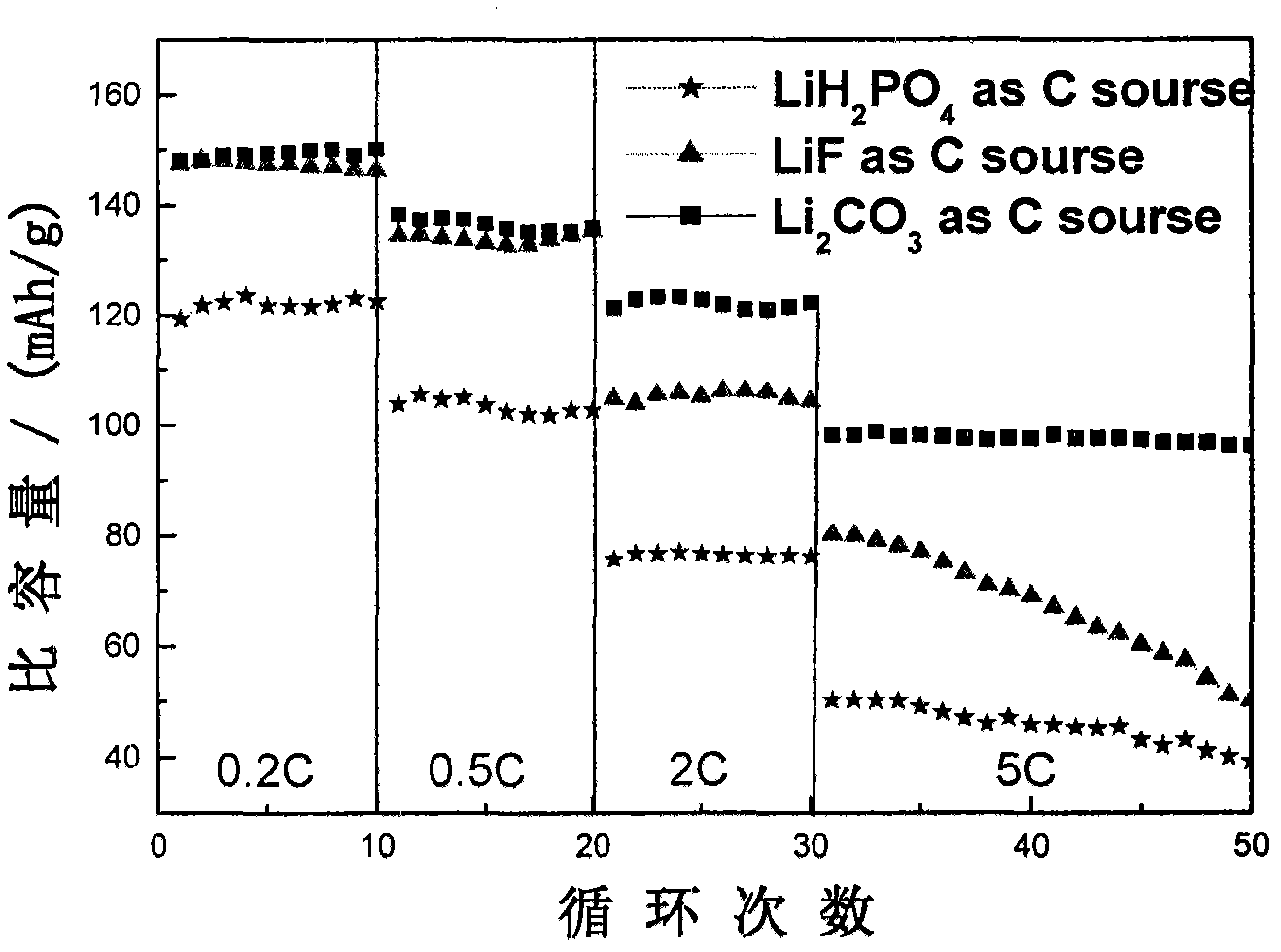

Metallic titanium doped carbon-coating lithium iron phosphate and preparation method thereof

A technology of carbon-coated lithium iron phosphate and metal titanium, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low tap density, poor electrical conductivity, material capacity attenuation, etc., and achieve the effect of low cost and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Accurately weigh 0.025molLi 2 CO 3 , 0.0225molFe 2 o 3 , 0.005molTiO 2 and 0.05molNH 4 h 2 PO 4 Put into the ball mill tank for batching;

[0024] (2) Add the prepared powder into acetone which is 4 times the volume of the powder, and then place it in a ball mill and rotate it at a rate of 250rpm / min for 5h;

[0025] (3) Dry the ground slurry in an oven at 110° C., and then add a saturated aqueous solution containing 2.2 g of citric acid to make a rheological phase precursor;

[0026] (4) Heat the above precursor at a heating rate of 1°C / min under an inert atmosphere, keep the temperature at 100°C for 2 hours, then raise the temperature to 400°C for 5 hours, take it out and grind it after cooling down in the furnace, and press it under a pressure of 200MPa into a compact cylinder;

[0027] (5) Heat up the pressed cylinder to 850°C for 12 hours at a constant temperature in a high-purity nitrogen atmosphere, and then cool down to room temperature with the fur...

Embodiment 2

[0031] (1) Accurately weigh 0.025molLi 2 CO 3 , 0.025molFe 2 o 3 and 0.05molNH 4 h 2 PO 4 Put into the ball mill tank for batching;

[0032] (2) Add the prepared powder into acetone which is 4 times the volume of the powder, and then place it in a ball mill and rotate it at a rate of 250rpm / min for 5h;

[0033] (3) Dry the ground slurry in an oven at 110° C., and then add a saturated aqueous solution containing 2.2 g of citric acid to make a rheological phase precursor;

[0034] (4) Heat the above precursor at a heating rate of 1°C / min under an inert atmosphere, keep the temperature at 100°C for 2 hours, then raise the temperature to 400°C for 5 hours, take it out and grind it after cooling down in the furnace, and press it under a pressure of 200MPa into a compact cylinder;

[0035] (5) The pressed cylinder was heated to 850° C. for 12 h at a constant temperature in an inert atmosphere, and the temperature was lowered to room temperature with the furnace to obtain 8.7 g...

Embodiment 3

[0038] (1) Accurately weigh 0.025molLi 2 CO 3 , 0.02325molFe 2 o 3 , 0.0035molTiO 2 and 0.05molNH 4 h 2 PO 4 Put into the ball mill tank for batching;

[0039] (2) Add the prepared powder into acetone which is 4 times the volume of the powder, and then place it in a ball mill and rotate it at a rate of 250rpm / min for 5h;

[0040] (3) Dry the ground slurry in an oven at 110° C., and then add a saturated aqueous solution containing 2.2 g of citric acid to make a rheological phase precursor;

[0041] (4) Heat the above precursor at a heating rate of 1°C / min under an inert atmosphere, keep the temperature at 100°C for 2 hours, then raise the temperature to 400°C for 5 hours, take it out and grind it after cooling down in the furnace, and press it under a pressure of 200MPa into a compact cylinder;

[0042] (5) The pressed cylinder was heated to 850° C. for 12 h at a constant temperature in an inert atmosphere, and the temperature was lowered to room temperature with the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com