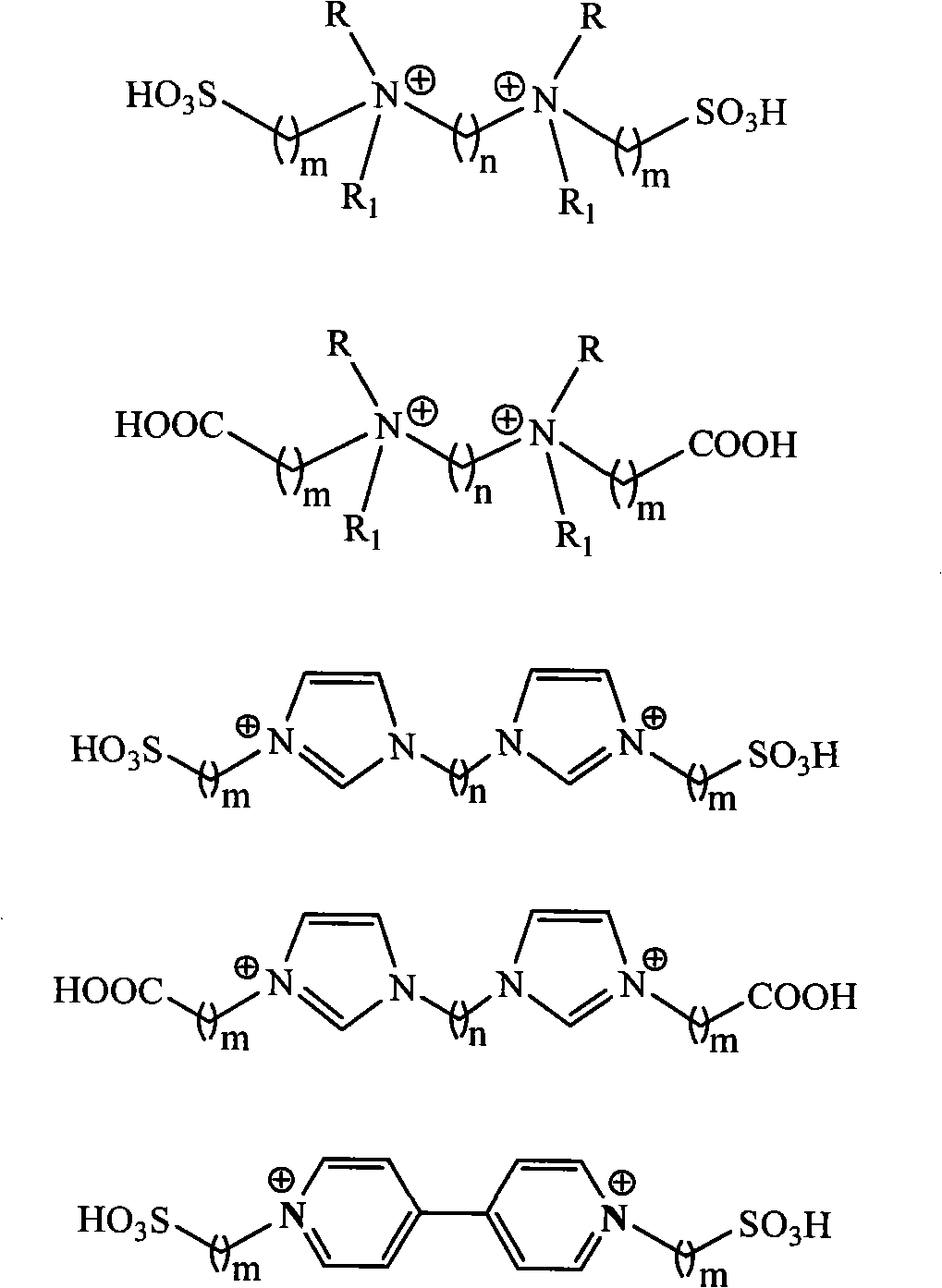

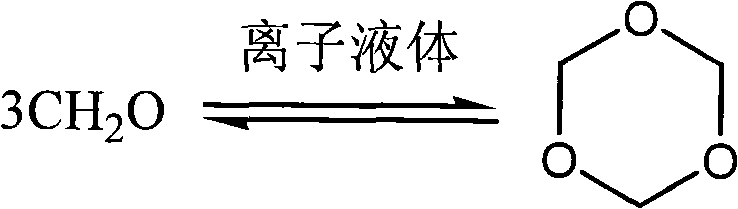

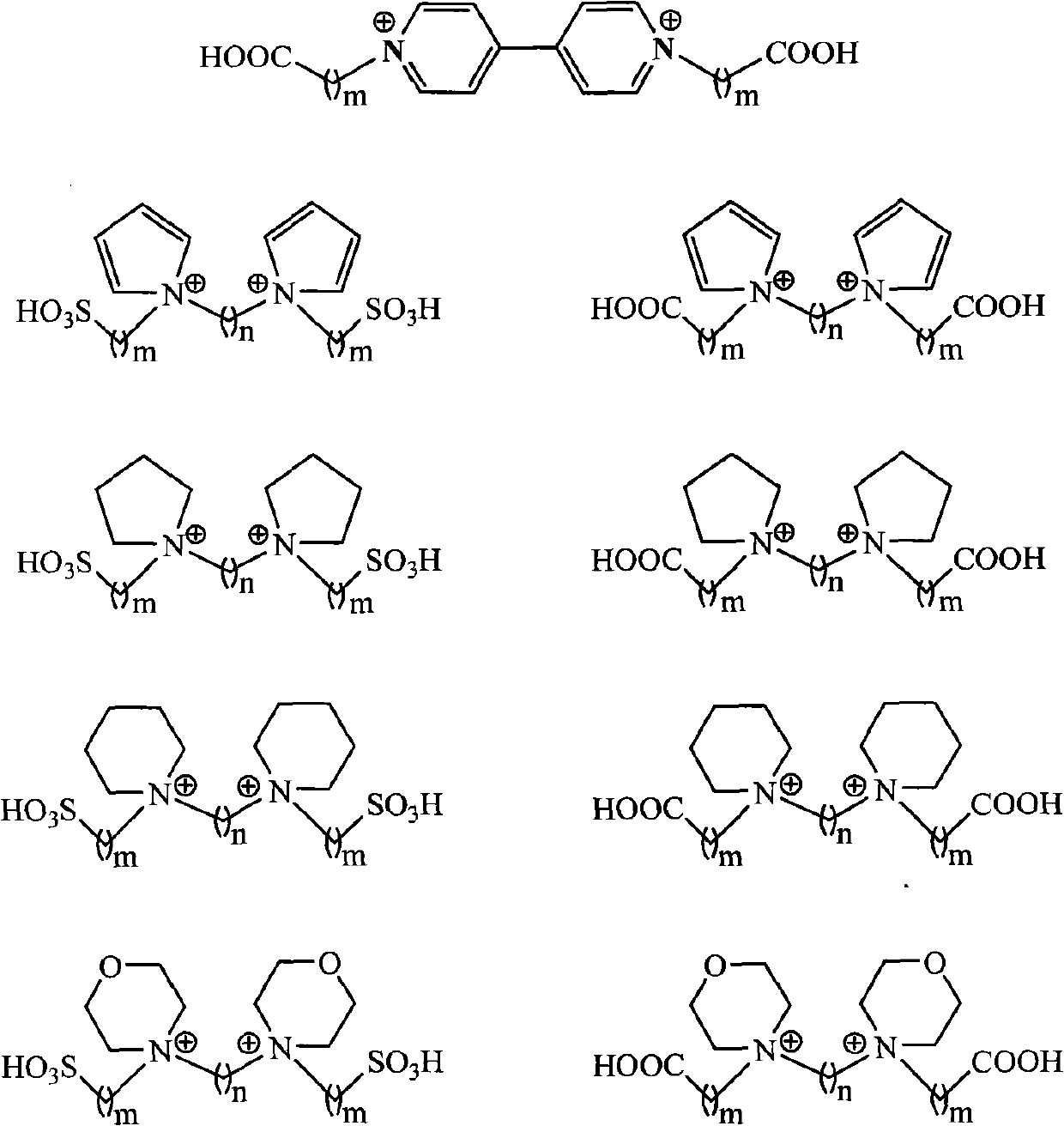

Method for synthesizing trioxymethylene by catalyzing formaldehyde cyclization reaction through bifunctional ionic liquid

A technology of ionic liquid and paraformaldehyde, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of low concentration of paraformaldehyde, high equipment requirements, Harsh operating conditions and other issues, to achieve the effect of good repeated use, high product selectivity, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A catalytic reaction-rectification device is adopted, wherein the rectification section is a glass packed tower with an inner diameter of 26 mm and a height of 300 mm. The reaction kettle is a 250mL glass three-necked bottle. 200g of 50.0wt.% formaldehyde aqueous solution and 4.0g of ionic liquid 1 were successively added into the reaction kettle. Heating is fully refluxed to be stable, and the reflux ratio R=2 is adjusted, and the azeotrope of formaldehyde, paraformaldehyde and water is steamed from the top of the tower (paraformaldehyde synthesis liquid), and the continuous feed (50.0wt.% Formaldehyde aqueous solution), the feed rate is 20g / h. The temperature of the reaction kettle was controlled at 97-98°C, the temperature at the top of the tower was 92-94°C, and the reaction was carried out for 4 hours to obtain 80g of paraformaldehyde synthesis liquid. The content of each component was analyzed by chromatography and quantified by the internal standard method. The...

Embodiment 2

[0031] Same as Example 1, using ionic liquid 2 as catalyst. The content of paraformaldehyde in the synthesis liquid is 37.0wt.%, the content of formaldehyde is 13.9wt.%, the content of methanol is 0.4wt.%, and the content of formic acid is 182.3ppm. The paraformaldehyde selectivity is 100%.

Embodiment 3

[0033] Same as Example 1, using ionic liquid 3 as catalyst. The content of paraformaldehyde in the synthesis liquid is 18.0wt.%, the content of formaldehyde is 23.8wt.%, the content of methanol is 0.8wt.%, and the content of formic acid is 101.4ppm. The paraformaldehyde selectivity is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com