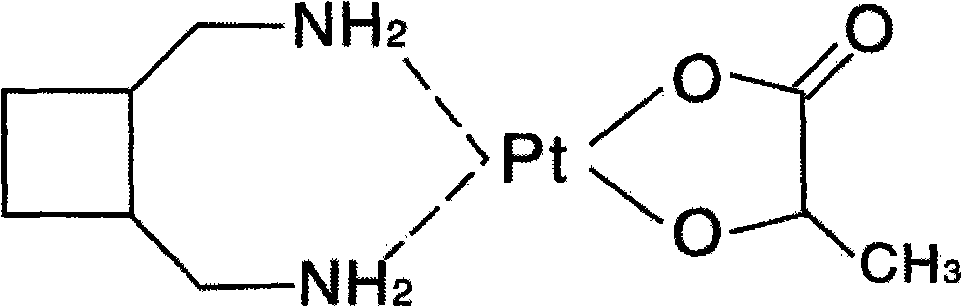

Method for preparing lobaplatin trihydrate by usingoxalate

A technology of lobaplatin trihydrate and oxalate, applied in the field of preparation of lobaplatin trihydrate, can solve the problems of incomplete reaction, low lobaplatin yield, unstable properties, etc. Conducive to the effect of synthesis and complete reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

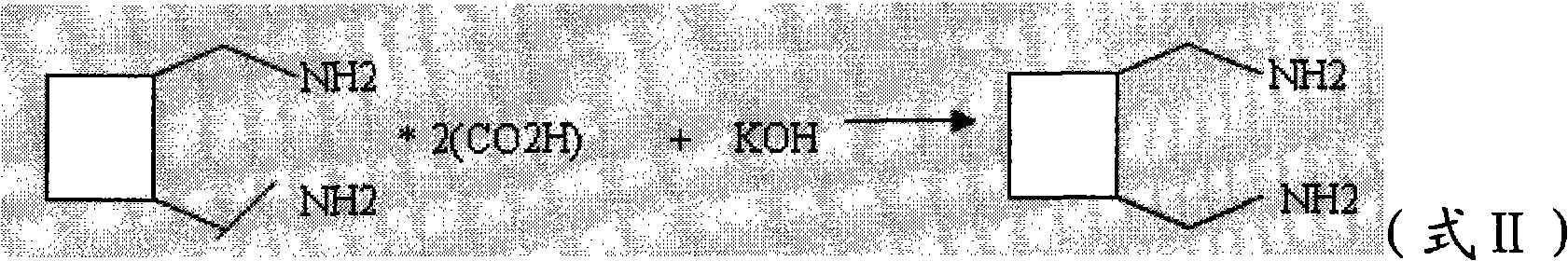

[0055] The preparation of used raw material diaminomethylcyclobutane oxalate

[0056] (1) Take 200ml of acrylonitrile, add 0.05g of Fecl3 and 0.044g of p-methoxyphenol at a temperature of 215°C and pressurize nitrogen to 17bar, and mix and react for 8 hours. After the reaction is complete, 20ml of dark red liquid is obtained. After distillation at 170-180°C, 10g of crude dicyanocyclobutane can be obtained, the cis-trans ratio is about 4:6, and then the crude product is distilled at 140-160°C, rectified and cis-trans converted to obtain trans-dicyanocyclobutane Cyclobutane 6.5g, melting point 37.5°C;

[0057] (2), after feeding ammonia gas into the trans-dicyanocyclobutane, the temperature rose to 70-85°C, the hydrogen gas was pressurized to 20bar, activated nickel was catalyzed, the reaction time was 20h, and 16ml of light yellow liquid was obtained. That is, trans-diaminomethylcyclobutane;

[0058] (3) 16ml of trans-diaminomethylcyclobutane and 3.5g of anhydrous oxalic acid...

Embodiment 2

[0059] Embodiment 2: the preparation of lobaplatin trihydrate

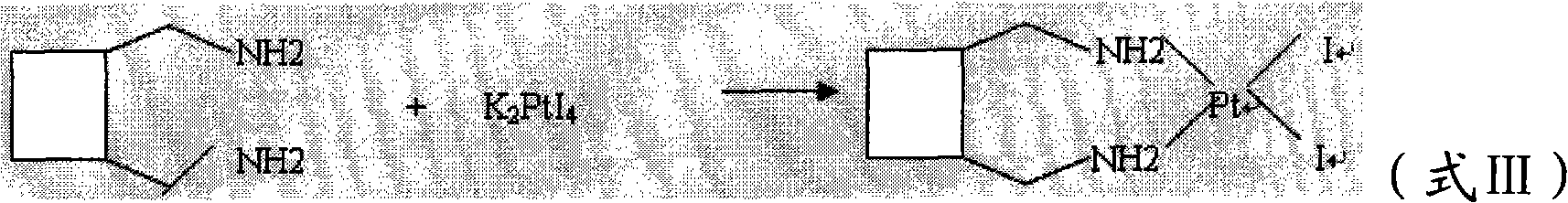

[0060] 1. Synthesis and preparation of diiodide

[0061] 1.1 Add 41.5g of potassium chloroplatinite into 120ml of purified water, stir to dissolve completely, and completely dissolve 99.6g of potassium iodide in 120ml of purified water under dark conditions, then add it into the solution of potassium chloroplatinite and stir for 30 minutes;

[0062] 1.2 Dissolve 31.2g of oxalate and 22.4g of potassium hydroxide in 200ml of purified water respectively, mix and react the two for 20 minutes, remove impurities by suction filtration, measure the pH value to 10, then add to the solution of 1.1, avoid light and stir for reaction 120 minutes;

[0063] 1.3 After the reaction is finished, filter the feed liquid with suction, rinse the filter cake with purified water, 150ml of water each time, until the washed water is free of chloride when detected with 2% silver nitrate solution, and filter the filter cake at 45-55°C Aft...

Embodiment 3

[0078] Preparation of lobaplatin trihydrate

[0079] 1. Synthesis and preparation of diiodide

[0080] 1.1 Add 23.1g of potassium chloroplatinite into 100ml of purified water, stir to dissolve completely, and completely dissolve 46.2g of potassium iodide in 60ml of purified water under dark conditions, then add it into the potassium chloroplatinite solution and stir for 20 minutes;

[0081] 1.2 Dissolve 20g of oxalate and 16.7g of potassium hydroxide in 150ml of purified water respectively, mix and react the two for 10 minutes, filter to remove impurities, measure the pH value to 11, then add to the solution of 1.1, and stir in the dark for 100 minute;

[0082] 1.3 After the reaction is finished, filter the feed liquid with suction, rinse the filter cake with purified water, 100ml of water each time, until the washed water is free of chloride when detected with 2% silver nitrate solution, and filter the cake at 45-55°C Vacuum drying for 15 hours gave 31 g of the crude produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com