Acrylate/silicone-acrylate compound emulsion and method for preparing same

An acrylate, silicone-acrylic emulsion technology, used in the field of latex paint, can solve the problems of poor emulsion stability, easy phase separation, poor weather resistance and adhesion, etc., and achieves good compatibility, good hydrophobicity, practical solidification. The effect of high content and monomer conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

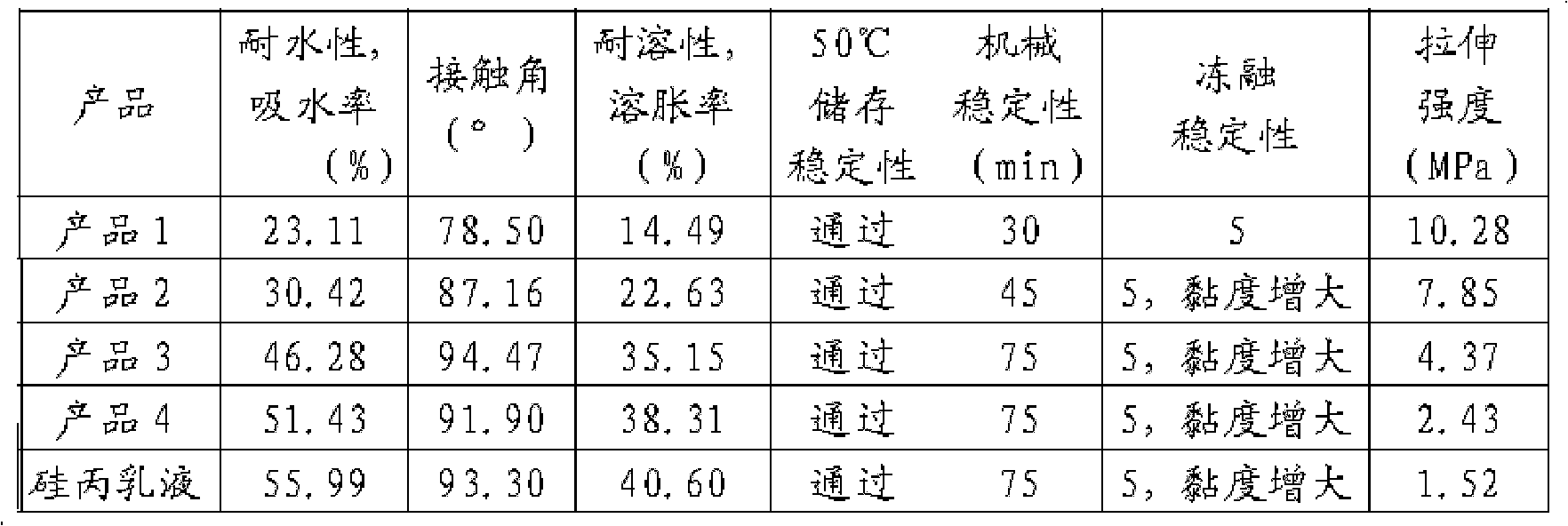

Image

Examples

Embodiment 1

[0036] ①Preparation of base liquid A: Add 135g of deionized water, 0.4g of polyoxyethylene nonyl ether ammonium sulfate, 0.15g of sodium bicarbonate , be heated up to the temperature in the kettle reaches 78 ℃;

[0037] ② Preparation of monomer solution B: Stir and mix all the monomers into a uniform solution, including 117.3g of n-butyl acrylate, 105.2g of methyl methacrylate, and 2.5g of functional monomer acrylic acid;

[0038] ③Preparation of initiator emulsifier mixed solution C: add 0.6g polyoxyethylene nonyl ether ammonium sulfate and 0.5g ammonium persulfate to 85g deionized water, stir to dissolve;

[0039] ④Preparation of post-addition initiator solution D: add 0.075g tert-butyl hydroperoxide and 0.075g diaobai to 30g deionized water, stir to dissolve;

[0040] ⑤ Add 14gB into the reactor, when the temperature in the kettle reaches 78℃, add 20gC, after 10-20min, add the remaining B and C into the reactor at the same time through the constant flow pump, the dropping ...

Embodiment 2

[0043]①Preparation of base liquid A: Add 140g deionized water, 0.7g polyoxyethylene octyl ether ammonium sulfate, 0.22g ammonium bicarbonate , heated up until the temperature in the kettle reached 80°C;

[0044] ② Preparation of monomer solution B: Stir and mix all the monomers into a uniform solution, including 116.9 g of n-butyl acrylate, 107 g of methyl methacrylate, and 6.1 g of functional monomer acrylic acid;

[0045] ③Preparation of initiator emulsifier mixed solution C: add 0.9g polyoxyethylene octyl ether ammonium sulfate and 1.4g potassium persulfate to 87g deionized water, stir to dissolve;

[0046] ④Preparation of post-addition initiator solution D: Add 0.12g tert-butyl hydroperoxide and 0.12g diaobai to 31g deionized water, stir to dissolve;

[0047] ⑤Add 21gB into the reactor, when the temperature in the kettle reaches 80℃, add 29gC, after 10-20min, add the remaining B and C into the reactor at the same time through the constant flow pump, the dropping time is c...

Embodiment 3

[0050] ①Preparation of base liquid A: Add 143g of deionized water, 1.0g of polyoxyethylene dinonyl ether ammonium sulfate, and 0.36g of ammonia into a reactor with a stirrer, condenser, and constant-flow pump feeding device, Raise the temperature until the temperature in the kettle reaches 84°C;

[0051] ② Preparation of monomer solution B: Stir and mix all the monomers into a uniform solution, including 122.6 g of ethyl acrylate, 110.7 g of methyl methacrylate, and 8.7 g of functional monomer monobutyl itaconate;

[0052] ③Preparation of initiator emulsifier mixed solution C: add 1.3g of polyoxyethylene dinonyl ether ammonium sulfate and 1.7g of potassium persulfate-potassium thiosulfate initiator into 90g of deionized water, and stir to dissolve;

[0053] ④Preparation of post-addition initiator solution D: add 0.19g tert-butyl hydroperoxide and 0.19g diaobai to 33g deionized water, stir to dissolve;

[0054] ⑤Add 27gB into the reactor, when the temperature in the kettle rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com