Preparation method of high infrared reflection titanate nano-powder

A nano-powder and infrared reflection technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as poor infrared reflection performance, uneven doping of products, complicated process routes, etc., and achieve low cost, decentralized Good performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

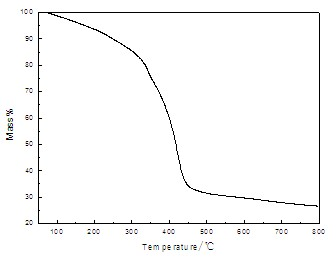

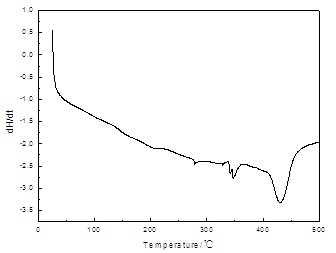

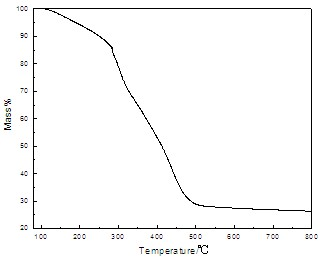

Image

Examples

Embodiment 1

[0030] ① Disperse 7 parts by weight of acrylic acid in 3 parts by weight of deionized water, and fully dissolve it under magnetic stirring to obtain an aqueous solution of acrylic acid A;

[0031] ② Weigh nickel acetate and n-butyl titanate, add them to the acrylic acid aqueous solution A in step ①, and dissolve under magnetic stirring to obtain a homogeneous system B, wherein the molar ratio of nickel acetate and n-butyl titanate is 1: 1. The weight ratio of n-butyl titanate to acrylic acid aqueous solution A is 15:100;

[0032] 3. Under the condition of magnetic stirring, the deionized aqueous solution of ammonium persulfate with a weight content of 2% is added to the homogeneous system B in step 2. to obtain solution C. The weight ratio is 0.05:1;

[0033] ④ the solution C obtained in the step ③ at 100 ℃ Heat and stir for 25 minutes to make the system completely polymerized, then dry at 250°C for 2 hours to obtain a solid, cool and grind, then place in a muffle furnace, a...

Embodiment 2

[0036] ① Disperse 10 parts by weight of acrylic acid in 4 parts by weight of deionized water, and fully dissolve it under magnetic stirring to obtain an aqueous solution of acrylic acid A;

[0037] ② Weigh chromium acetate and n-butyl titanate, add them to the acrylic acid aqueous solution A in step ①, and dissolve under magnetic stirring to obtain a homogeneous system B, wherein the molar ratio of chromium acetate and n-butyl titanate is 2: 3. The weight ratio of n-butyl titanate to acrylic acid aqueous solution A is 20:100;

[0038] 3. Under the condition of magnetic stirring, the deionized aqueous solution of ammonium persulfate with a weight content of 5% is added to the homogeneous system B in step 2. to obtain solution C, the mixture of ammonium persulfate and acrylic acid in step 1. The weight ratio is 0.01:1;

[0039] 4. the solution C obtained in the step 3. at 80 ℃ Heat and stir for 15 minutes to completely polymerize the system, then dry at 180°C for 3 hours to ob...

Embodiment 3

[0042] ① Disperse 8 parts by weight of acrylic acid in 4 parts by weight of deionized water, and fully dissolve it under magnetic stirring to obtain an aqueous solution of acrylic acid A;

[0043] ② Weigh nickel acetate and n-butyl titanate, add them to the acrylic acid aqueous solution A in step ①, and dissolve under magnetic stirring to obtain a homogeneous system B, wherein the molar ratio of nickel acetate and n-butyl titanate is 1: 10. The weight ratio of n-butyl titanate to acrylic acid aqueous solution A is 25:100;

[0044] 3. Under the condition of magnetic stirring, the deionized aqueous solution of ammonium persulfate with a weight content of 2% is added to the homogeneous system B in step 2. to obtain solution C. The weight ratio is 0.05:1;

[0045] ④ the solution C obtained in the step ③ at 90 ℃ Heat and stir for 10 minutes to make the system completely polymerized, then dry at 200°C for 3 hours to obtain a solid, cool and grind, then place in a muffle furnace, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com