Styrene-butadiene vulcanized rubber and preparation method thereof

A technology for vulcanized rubber and styrene-butadiene rubber, which is applied in the field of modified styrene-butadiene vulcanized rubber, can solve the problems of decreased mechanical properties and poor rubber compatibility, and achieves the effects of improved heat aging resistance, easy implementation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

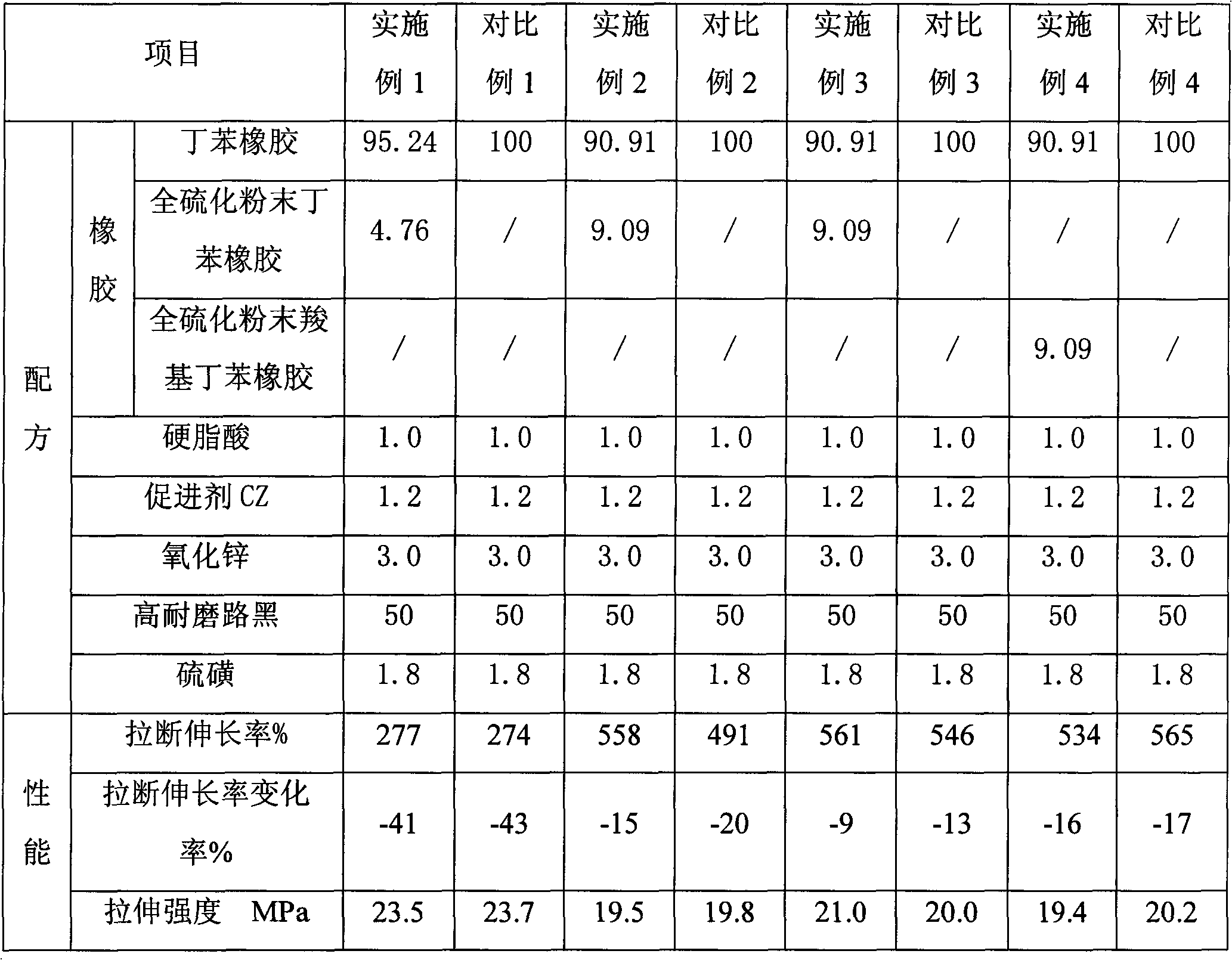

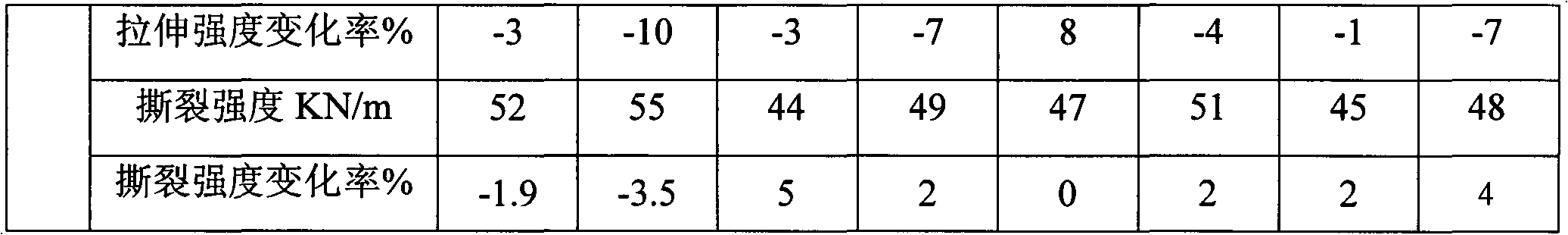

Embodiment 1

[0018] In styrene-butadiene emulsion (Sinopec Shanghai Gaoqiao branch, DB-7723), after adding cross-linking aid trimethylolpropane triacrylate by 1% of styrene-butadiene emulsion dry glue weight, carry out radiation vulcanization, radiation dose is 3kGy, after spray drying, a fully vulcanized powdered styrene-butadiene rubber with an average particle size of 150nm and a gel content of 91% was obtained.

[0019] First, set the initial temperature of the internal mixer at 50±3°C, and the rotor speed at 80r / min, add the prepared fully vulcanized powdered styrene-butadiene rubber and styrene-butadiene rubber (China Petroleum Corporation Jilin Petrochemical Branch, SBR1500) to masticate rubber 0.5-2mins, then add the required additives, continue to mix the rubber for 5mins, the mixing temperature is 150-170°C, then unload the rubber; then add the accelerator and vulcanizing agent on the open mill for mixing, and then vulcanize. The specific formula is shown in Table 1, wherein the ...

Embodiment 2

[0023] In styrene-butadiene emulsion (produced by Sinopec Lanhua Branch, DB-50), after adding cross-linking aid trimethylolpropane triacrylate by 1% of styrene-butadiene emulsion dry glue weight, carry out radiation vulcanization, radiation dose is 5kGy, after spray drying, the average particle size is 100nm, and the gel content is 89.1% fully vulcanized powdered styrene-butadiene rubber.

[0024] First, set the initial temperature of the internal mixer at 50±3°C, and the rotor speed at 80r / min, add the prepared fully vulcanized powdered styrene-butadiene rubber and styrene-butadiene rubber (China Petroleum Corporation Jilin Petrochemical Branch, SBR1500) to masticate rubber 0.5-2mins, then add the required additives, continue to mix the rubber for 5mins, the mixing temperature is 150-170°C, then unload the rubber; then add the accelerator and vulcanizing agent on the open mill for mixing, and then vulcanize. The specific formula is shown in Table 1, wherein the fully vulcaniz...

Embodiment 3

[0028] Except that the grade of styrene-butadiene rubber is changed to SBR2535, all the other are the same as in Example 2. The specific formula is shown in Table 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com