Method for preparing sequentially arranged bent silicon nano-wire array

A silicon nanowire array, orderly arrangement technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, to achieve the effect of mild reaction conditions and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

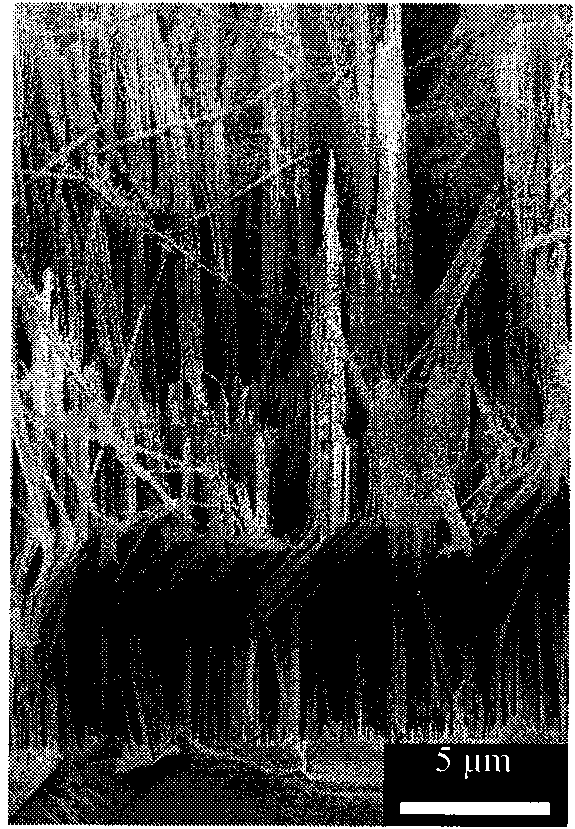

[0034] Example 1. Preparation of ordered array of bent silicon nanowires

[0035] The single crystal silicon wafer with a specific crystal orientation used in this embodiment is an N-type crystal orientation silicon wafer purchased from Tianjin Semiconductor Research Institute, with a resistivity of 0.015 ohm cm and a polished surface (mirror surface). In the experiment, silver nitrate, hydrofluoric acid aqueous solution (mass concentration is 40%) and deionized water are used to prepare an etching solution containing hydrofluoric acid concentration of 4.6mol / L and silver ion concentration of 0.04mol / L, and adding it to poly In a tetrafluoroethylene container; take an N-type crystalline silicon wafer, soak it in a chromic acid wash solution (prepared from 5 grams of potassium dichromate, 100 ml of concentrated sulfuric acid, and 10 ml of water) to remove organic pollutants on the surface of the silicon wafer, Then, it was treated with 10% hydrofluoric acid aqueous solution f...

Embodiment 2

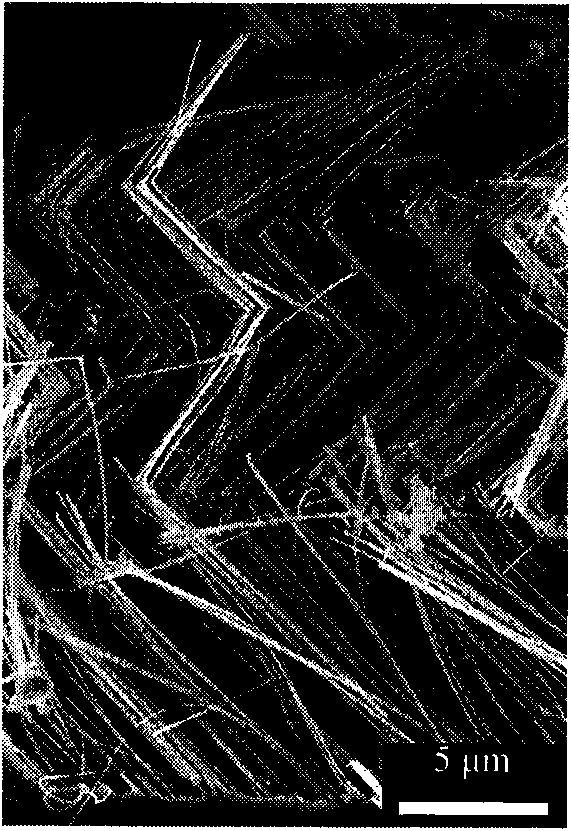

[0036] Example 2, Preparation of Orderly Arranged Bending Silicon Nanowire Arrays

[0037] According to the method of Example 1, the orderly arranged bent silicon nanowire array material is prepared, the difference is that the single crystal silicon wafer with a specific crystal orientation used in this example is a P-type crystal orientation silicon wafer (resistance Ratio: 0.015 ohm·cm), indicating that the method for preparing ordered arrays of bent silicon nanowires of the present invention has universal applicability. Observing the cross-sectional morphology of the silicon wafer under a scanning electron microscope, the obtained ordered array of bent silicon nanowires is as follows: figure 2 shown.

Embodiment 3

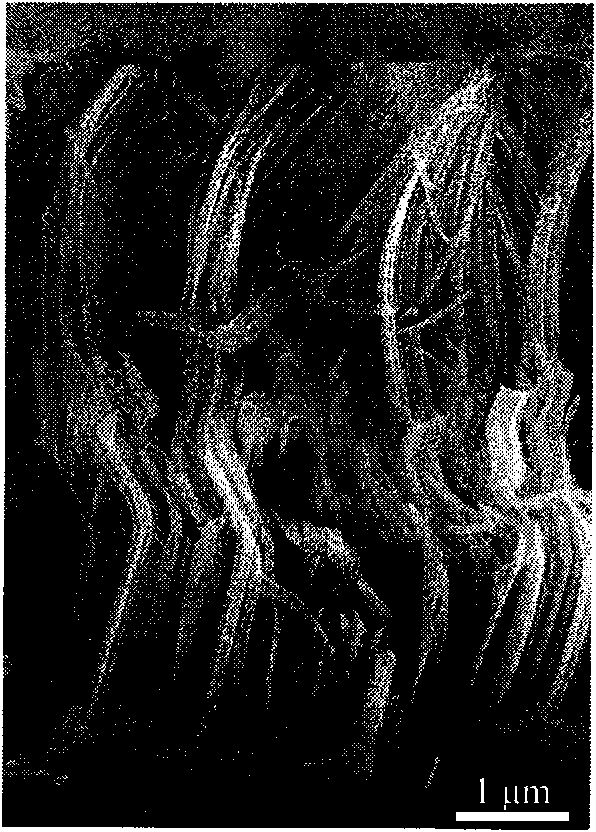

[0038] Example 3, Preparation of Orderly Arranged Bending Silicon Nanowire Arrays

[0039] According to the method of Example 1, the orderly arranged bent silicon nanowire array material is prepared, the difference is that the concentration of silver ions in the etching solution used in this example is 0.01mol / L, and the temperature used is 55 degrees Celsius. The obtained ordered array of bent silicon nanowires is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com