Modified self-insulating composite external wall material

An insulation material and self-insulation technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of prolonging the initial setting time, failure to increase the early strength of fly ash, damage and missing edges and corners. and other problems to achieve the effect of improving compressive strength and comprehensive performance, ensuring product and engineering quality, and reducing construction strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated below by way of examples.

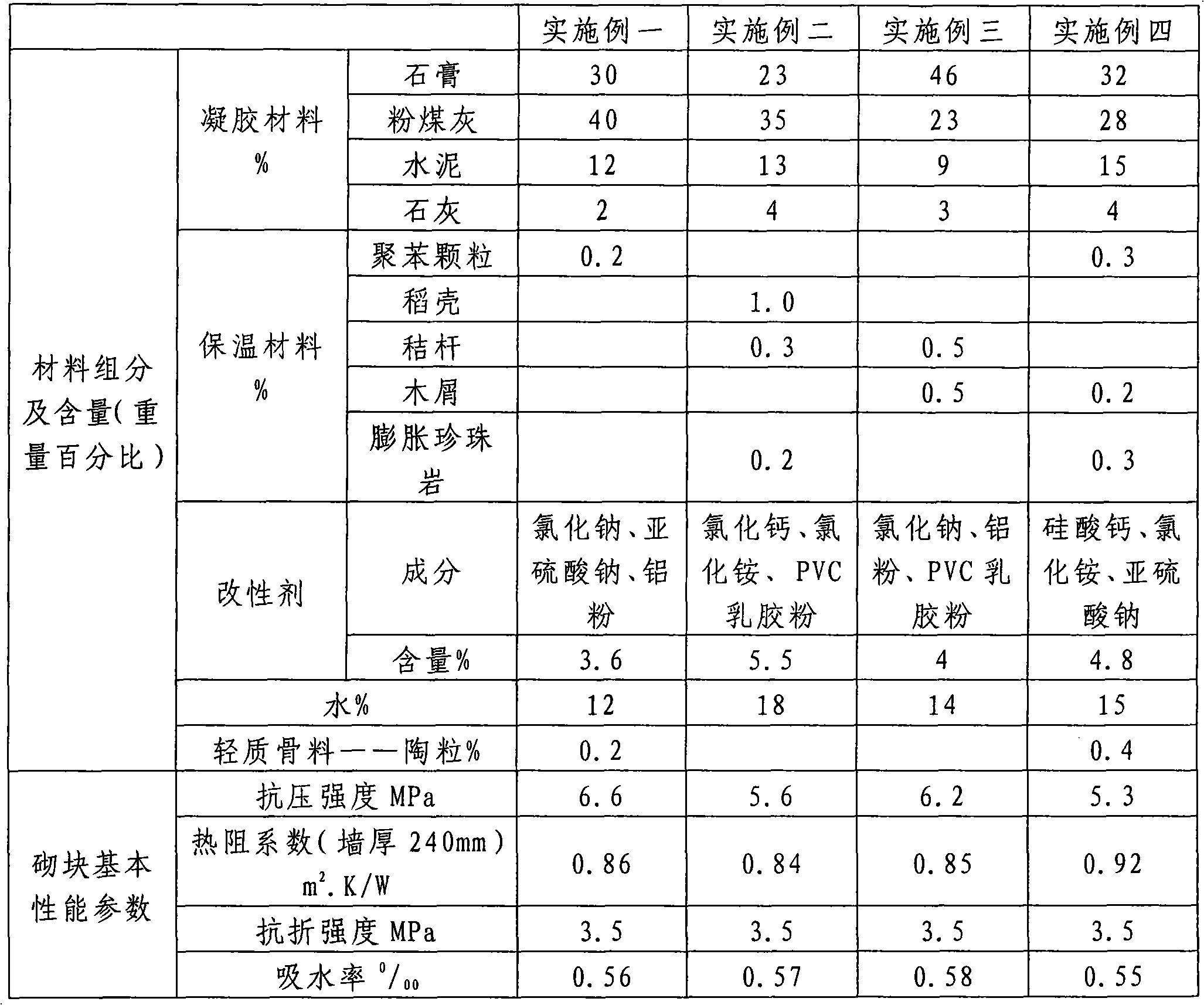

[0020] The components and contents of the exterior wall materials in Examples 1, 2, 3, and 4 and the basic performance parameters of the exterior wall blocks made after batching, water mixing, injection molding, and drying are as follows:

[0021]

[0022] Note: Among the insulation materials in the table, the diameter of polystyrene particles and expanded perlite is 0.2-3.0mm, the rice husk is natural flake, and the length of straw is 5-15mm after crushing. Rice husk, straw and sawdust are treated with anti-mildew and anti-insect treatment.

[0023] The basic performance parameters of the above-mentioned blocks are measured values, which are obviously better than the values specified in the relevant standards for gypsum building materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com