Glass fiber enhanced PET/PBT (Polyethylene Terephthalate)/(Polybutylene Terephthalate) alloy with high glossiness and low warping degree and preparation method thereof

A low-warpage, high-gloss technology, applied in the field of thermoplastic polymer materials, can solve the problems of high molding mold temperature, long molding cycle, low production energy consumption, etc., and achieve the effects of fast crystallization rate, low cost and low shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

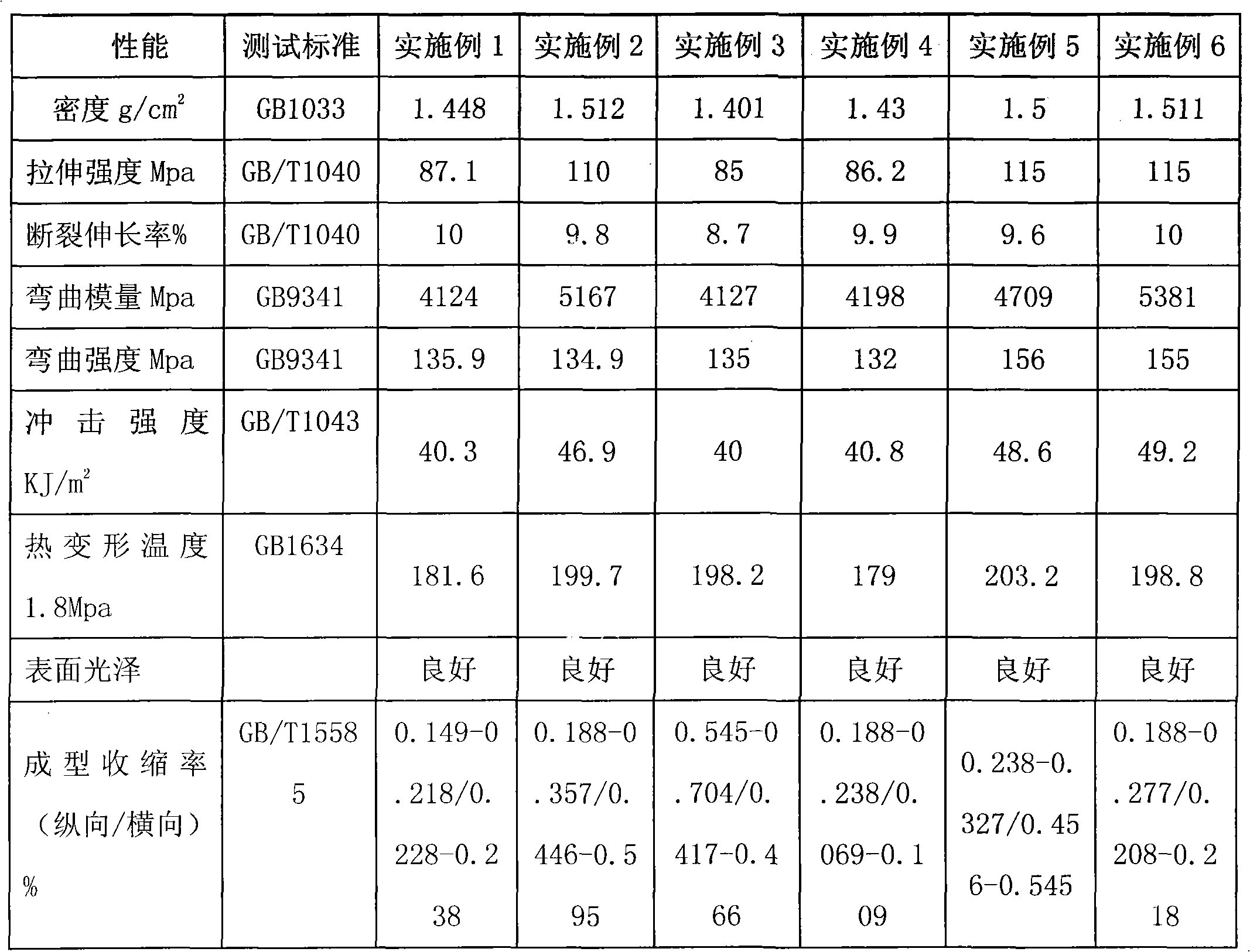

Examples

preparation example Construction

[0037] The preparation method of PET / PBT alloy of the present invention comprises:

[0038] Step 1. Weigh each component according to the above-mentioned mass percentage, and dry the weighed PET and PBT at a temperature of 110-130°C for more than 4 hours, and dry the other components at a temperature of 60-80°C More than 2 hours; this is because PET and PBT are easy to absorb moisture, so they must be dried before blending and modification;

[0039] Step 2. Put the dried PET, PBT, compatibilizer, antioxidant, nucleation accelerator, composite nucleation agent and processing aid into a high-speed mixer and mix them at room temperature for 5-15 minutes;

[0040] Step 3: Add the mixed material in Step 2 into the hopper of the twin-screw extruder, add the glass fiber from the glass fiber inlet in the middle of the twin-screw, melt and blend, extrude, water-cool, air-dry, and pelletize; The screw extruder can use a parallel twin-screw extruder with a screw diameter of 35-75mm;

...

Embodiment 1

[0044] Dry PET and PBT at 110°C for 4 hours, and dry the rest of the additives at 70°C for 2 hours. Weigh PET 40.5kg, PBT 35kg, compatibilizer 4kg, composite nucleating agent 3kg (including P2500.5kg, talcum powder 3kg), nucleation accelerator 1kg, antioxidant 10100.3kg, 1680.3kg, lubricant CBT 0.9kg ; Then mix in a high speed mixer for 10min. The uniformly mixed material is added to the hopper of the twin-screw extruder, and the temperature of each section is controlled at: Zone 1: 210°C; Zone 2: 220°C; Zone 3: 230°C; Zone 4: 240°C; Zone 5: 250°C ; Zone six: 240°C; Zone seven: 240°C; Zone eight: 230°C; Head temperature: 250°C, screw speed 350r / min, glass fiber 15kg is added from the glass fiber inlet in the middle of the twin-screw, and melted together Mixed extrusion, water cooling, air drying, pelletizing, and finally bagged into glass fiber reinforced PET / PBT alloy finished products.

Embodiment 2

[0046]Dry PET and PBT at 120°C for 4 hours, and dry the rest of the additives at 60°C for 2 hours. Weigh PET 30kg, PBT 30.3kg, compatibilizer 10kg, composite nucleating agent 8kg (wherein P2505kg, talcum powder 3kg), nucleating accelerator 1kg, antioxidant 10100.1kg, 1680.2kg, lubricant CBT 0.4kg; Mix in a high speed mixer for 10 min. The uniformly mixed material is added to the hopper of the twin-screw extruder, and the temperature of each section is controlled at: Zone 1: 210°C; Zone 2: 220°C; Zone 3: 230°C; Zone 4: 240°C; Zone 5: 250°C ; Zone 6: 250°C; Zone 7: 240°C; Zone 8: 230°C; Head temperature: 250°C, screw speed 320r / min, glass fiber 20kg is added from the glass fiber inlet in the middle of the twin-screw, and melted together Mixed extrusion, water cooling, air drying, pelletizing, and finally bagged into glass fiber reinforced PET / PBT alloy finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com