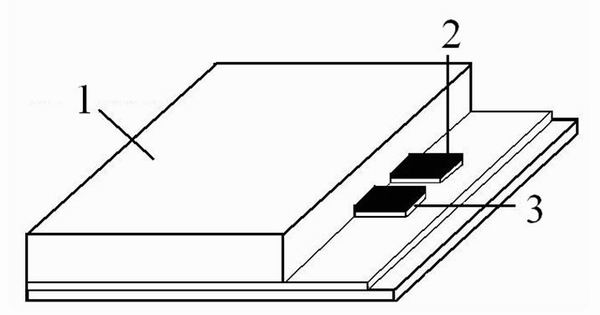

Method for directly preparing two-layer electrode by one-time silk-screen printing and used slurry thereof

A double-layer electrode and slurry technology, which is applied in the directions of gas discharge electrodes, electrode system manufacturing, sustain/scan electrodes, etc., can solve the problems of complex process and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

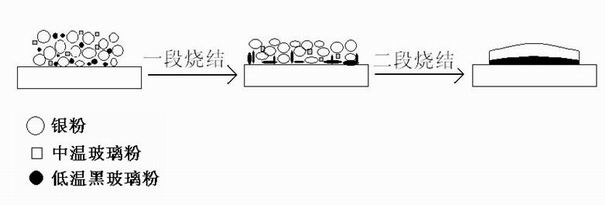

Method used

Image

Examples

Embodiment 1

[0084] Preparation of medium temperature glass powder:

[0085] The raw materials are weight ratio Bi 2 o 3 65%, SiO 2 6%, B 2 o 3 10%, ZnO 15%, BaO 2.5%, Al 2 o 3 1.5%, grind and mix well in a porcelain mortar. Put this batch material into a high alumina crucible, and melt it at 1000°C for 2 hours to melt into a glass state. Pour the molten glass into cold water, dry the glass slag in an incubator, mill it with a planetary ball mill until the particle size is about 1 μm, and dry it for later use. The melting temperature of glass is 450°C

[0086] Preparation of low temperature black glass powder:

[0087] The raw materials are weight ratio Bi 2 o 3 68%, SiO 2 14%, B 2 o 3 12%, ZnO 6%, grind and mix well in a porcelain mortar. Put this batch material into a high alumina crucible, melt at 1000°C for 2 hours, and melt into a glass state. Pour the molten glass into cold water, dry the glass slag in an incubator, mill it with a planetary ball mill until the ...

Embodiment 2

[0094] Preparation of medium temperature glass powder:

[0095] The raw materials are weight ratio Bi 2 o 3 65.4%, SiO 2 5.3%, B 2 o 3 14.3%, ZnO 12.1%, BaO 1.75%, Al 2 o 3 1.15% Grind in a porcelain mortar and mix well. Put this batch material into a high alumina crucible, and melt it at 1000°C for 2 hours to melt into a glass state. Pour the molten glass into cold water, dry the glass slag in an incubator, mill it with a planetary ball mill until the particle size is about 1 μm, and dry it for later use. The melting temperature of glass is 470 °C.

[0096] Preparation of low temperature black glass powder:

[0097] Prepared according to Example 1.

[0098] Prepare the organic vehicle:

[0099] Prepared according to Example 1.

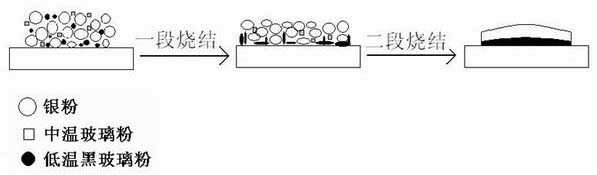

[0100] Preparation of photosensitive silver paste:

[0101] 4.0% medium-temperature lead-free glass powder, 10% low-temperature black glass powder, 56.0% silver powder, 5% ethoxylated trimethylolpropane triacrylate, 1-p-methyl...

Embodiment 3

[0104] Preparation of medium temperature glass powder:

[0105] Prepared according to Example 1.

[0106] Preparation of low temperature black glass powder:

[0107] The raw materials are weight ratio Bi 2 o 3 73.6%, SiO 2 6.2%, B 2 o 3 6.2%, ZnO 14%, grind and mix well in a porcelain mortar. Put this batch material into a high alumina crucible, melt at 1000°C for 2 hours, and melt into a glass state. Pour the molten glass into cold water, dry the glass slag in an incubator, mill it with a planetary ball mill until the particle size is about 1 μm, and dry it for later use. The lead-free glass powder with a weight ratio of 95% and 5% Co 3 o 4 Grind and mix evenly in a porcelain mortar, put into a high alumina crucible, and melt at 1000 °C for 1 hour. The glass liquid was quenched in water, and after being ball-milled in a planetary ball mill to an average particle size of 2 μm, the glass powder was dried in an incubator. The melting temperature of glass powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com