Vegetarian diet flavor juice and preparation method thereof

An umami and vegetarian technology, applied in the field of food processing, can solve problems such as the inability to use vegetarian food, and achieve the effects of enhancing aroma and taste, improving nutritional value and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

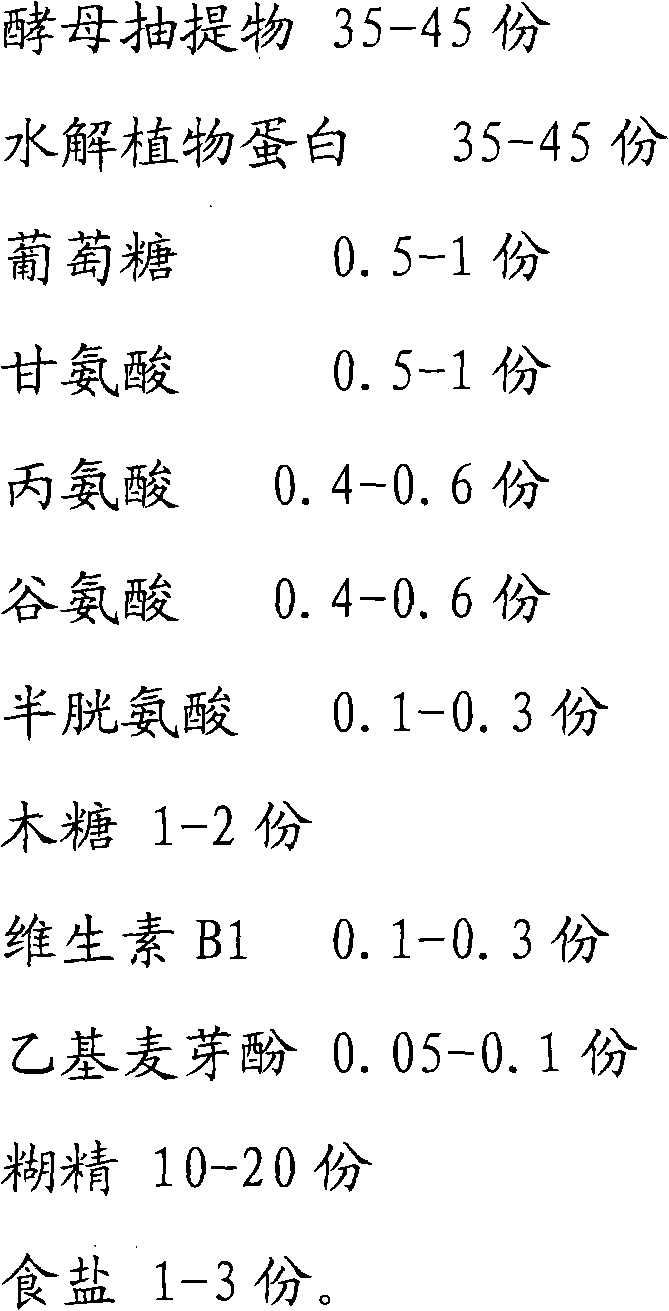

[0037] Embodiment 1: Preparation of vegetarian umami juice according to the present invention

[0038] Raw material composition: 35kg of yeast extract, 35kg of hydrolyzed vegetable protein (Chengdu Chelation Biotechnology Co., Ltd.), 1kg of xylose, 10.1kg of vitamin B, 0.05kg of spinach powder (produced by Xinghua Weidan Food Co., Ltd.), onion extract (produced by Jiangxi Yabanna Industry Co., Ltd.) 0.05kg, mushroom extract (the mushroom powder produced by Xinghua Weidan Food Co., Ltd.) 1kg.

[0039] The preparation method comprises the following steps:

[0040] (1) Dilute the yeast extract to 30% dry matter concentration;

[0041] (2) Mix yeast extract, hydrolyzed vegetable protein, xylose, and vitamin B1;

[0042] (3) heating at a temperature of 90° C. for 120 minutes;

[0043] (4) Concentrating the gained in step (3) to a dry matter concentration of 50% to prepare the reaction base material;

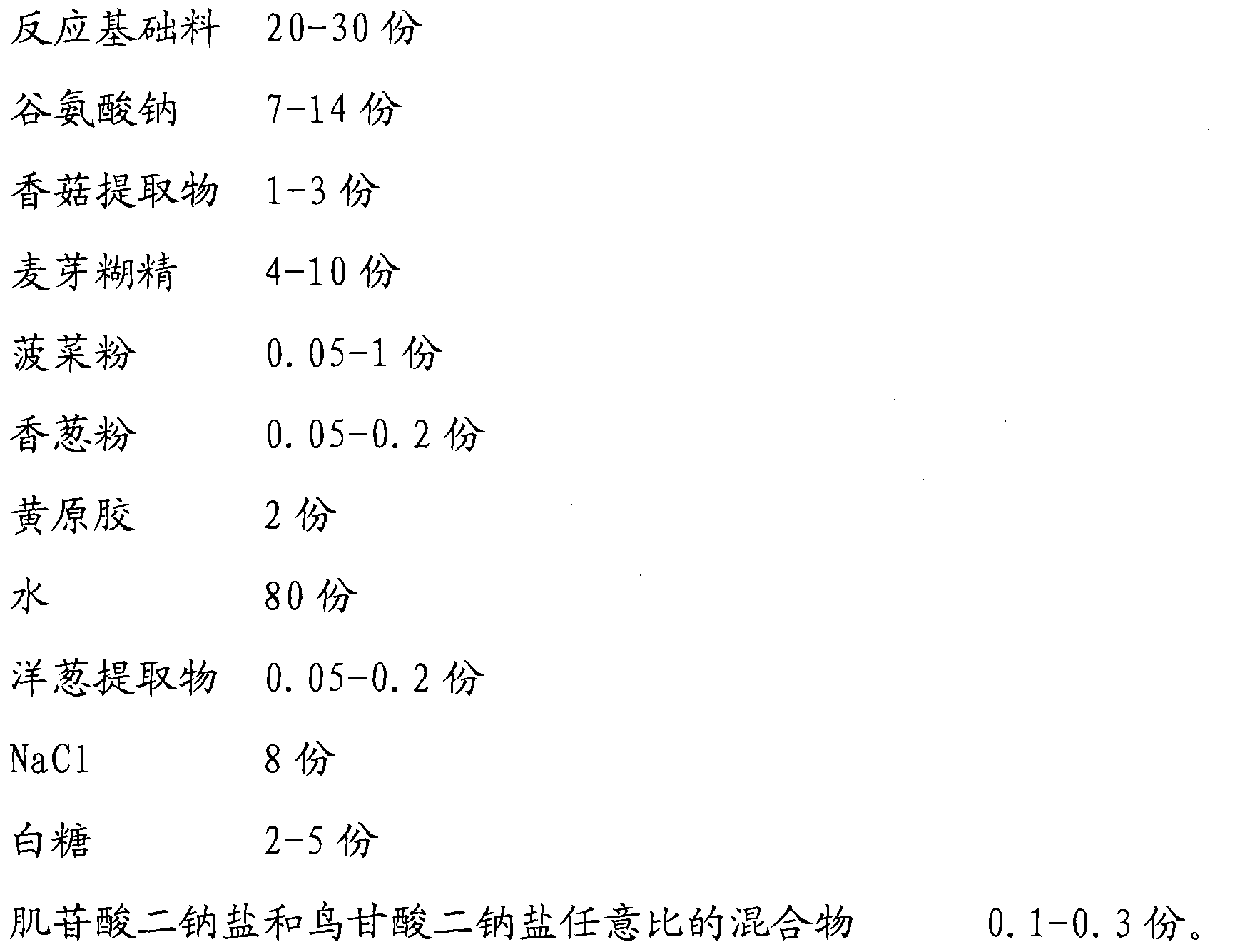

[0044] (5) mixing the reaction base material obtained in step (4), spinach po...

Embodiment 2

[0046] Embodiment 2: preparation of vegetarian umami juice according to the present invention

[0047] Yeast extract 45kg, hydrolyzed vegetable protein (Baoding Xinweikang Food Ingredients Co., Ltd.) 45kg, xylose 2kg, vitamin B10.3kg, spinach powder 1kg, onion extract (produced by Jiangxi Yabana Industry Co., Ltd.) 0.2kg, Mushroom extract (Xiamen Zhongkun Biotechnology Co., Ltd.) 3kg.

[0048] The preparation method comprises the following steps:

[0049] (1) Dilute the yeast extract to 40% dry matter concentration;

[0050] (2) Mix yeast extract, hydrolyzed vegetable protein, xylose, and vitamin B1;

[0051] (3) heating at a temperature of 110° C. for 30 minutes;

[0052] (4) Concentrating the gained in step (3) to a dry matter concentration of 70% to prepare a reaction base material;

[0053] (5) mixing the reaction base material obtained in step (4), spinach powder, onion extract, and shiitake mushroom extract;

[0054] (6) heating at a temperature of 110°C for 20-60 m...

Embodiment 3

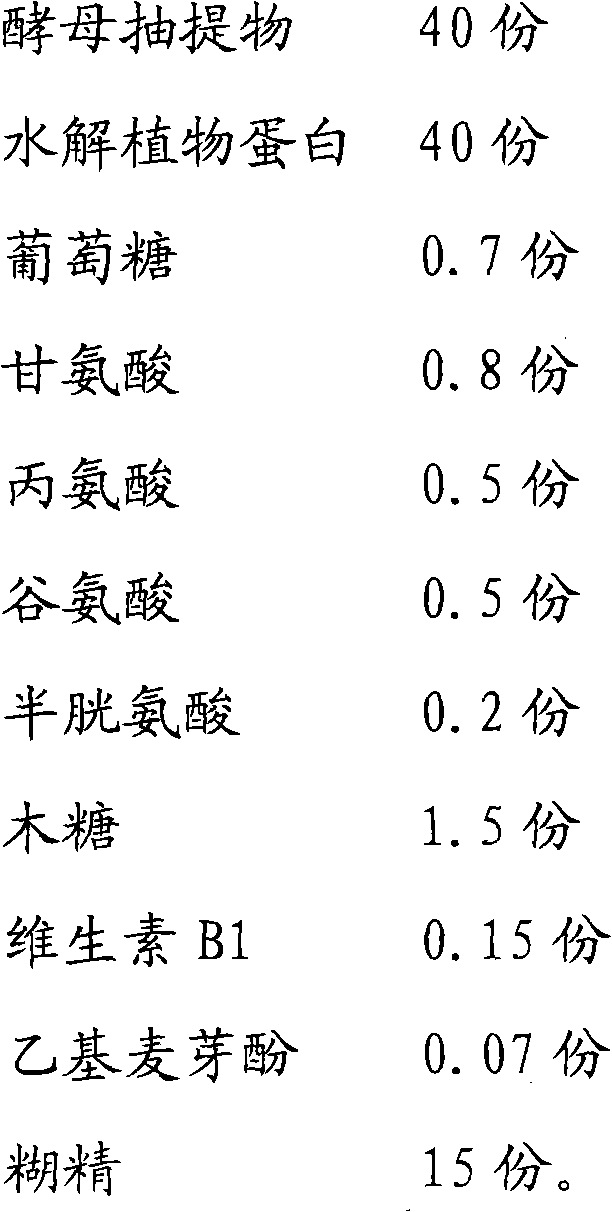

[0055]Embodiment 3: prepare the vegetarian umami juice of the present invention

[0056] Raw material composition: 40kg of yeast extract, 40kg of hydrolyzed vegetable protein, 1.5kg of xylose, 10.2kg of vitamin B, 0.1kg of spinach powder (produced by Jiangxi Yabana Industry Co., Ltd.), onion extract (Xinghua Beichen Food Co., Ltd. ) 0.15kg, shiitake mushroom extract (Xiamen Zhongkun Biotechnology Co., Ltd.) 2.5kg, glucose 0.5kg, glycine 0.5kg, alanine 0.4kg, glutamic acid 0.4kg, cysteine 0.1kg, ethyl maltol 0.05kg, dextrin 10kg and salt 1kg.

[0057] Preparation:

[0058] (1) Dilute the yeast extract to 35% dry matter concentration;

[0059] (2) Mix the raw materials, the raw materials are yeast extract diluted in step 1, hydrolyzed vegetable protein, xylose, vitamin B1 and glucose, glycine, alanine, glutamic acid, cysteine of the above weight , ethyl maltol, dextrin and salt;

[0060] (3) heating at a temperature of 95° C. for 60 minutes;

[0061] (4) concentrating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com