Method for preparing pemetrexed disodium 2.5 water crystal

A pemetrexed disodium and crystallization technology, which is applied in the field of preparation of 2.5 hydrate crystals, can solve the problems of difficult removal of solvent residues, increased production costs, and difficulty in obtaining pure 2.5 hydrate forms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Under the protection of argon, add 10 g of pemetrexed disodium into 60 ml of water, stir and heat up until the system dissolves;

[0026] Then the aqueous solution was added dropwise to 480ml of absolute ethanol at room temperature for 30 minutes, and after the drop was completed, the temperature was lowered to 5° C. and kept for 30 minutes. After filtering, the filter cake was dried under reduced pressure at 50° C. to obtain 9.5 g of pemetrexed disodium 2.5 hydrate.

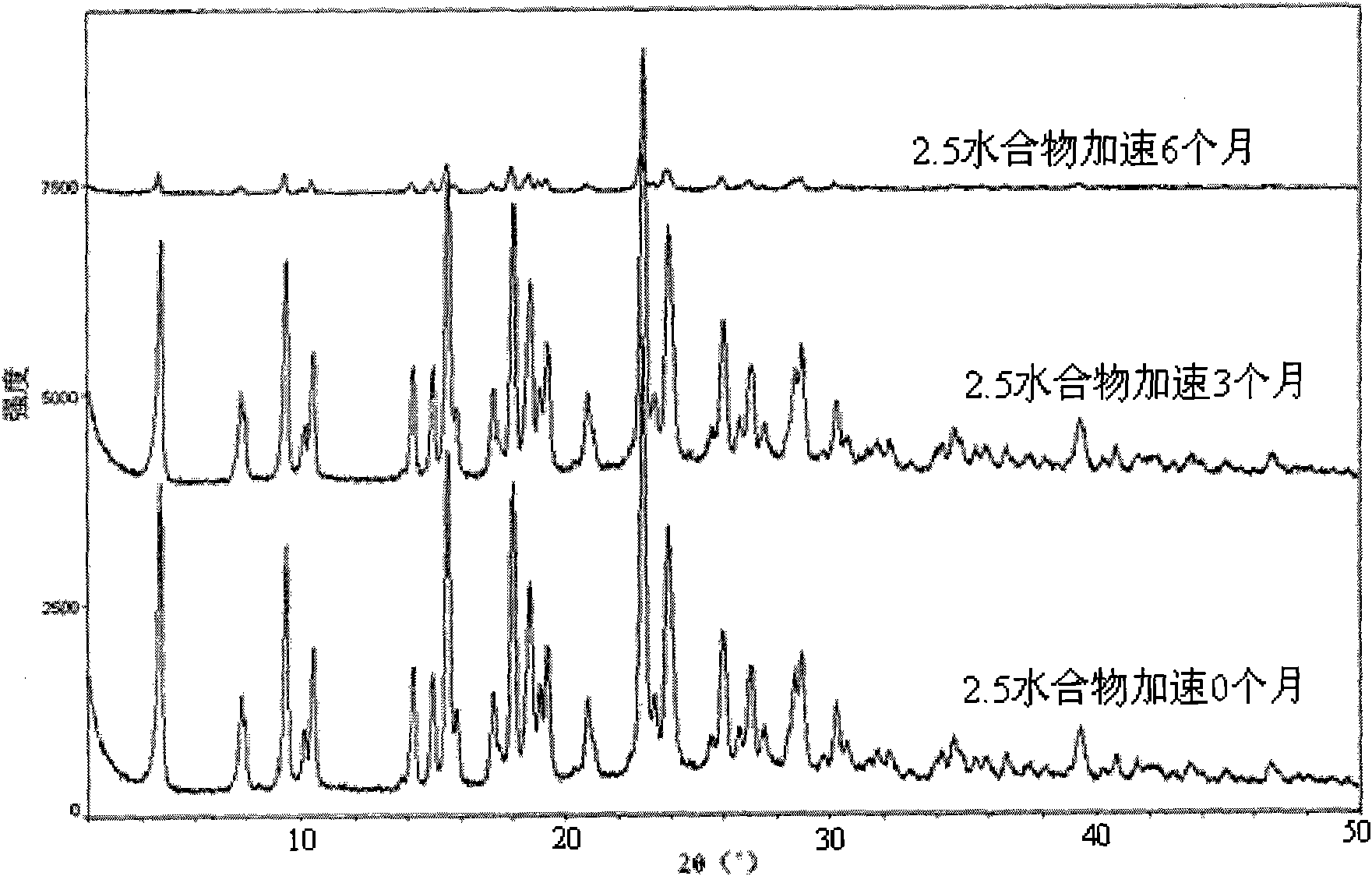

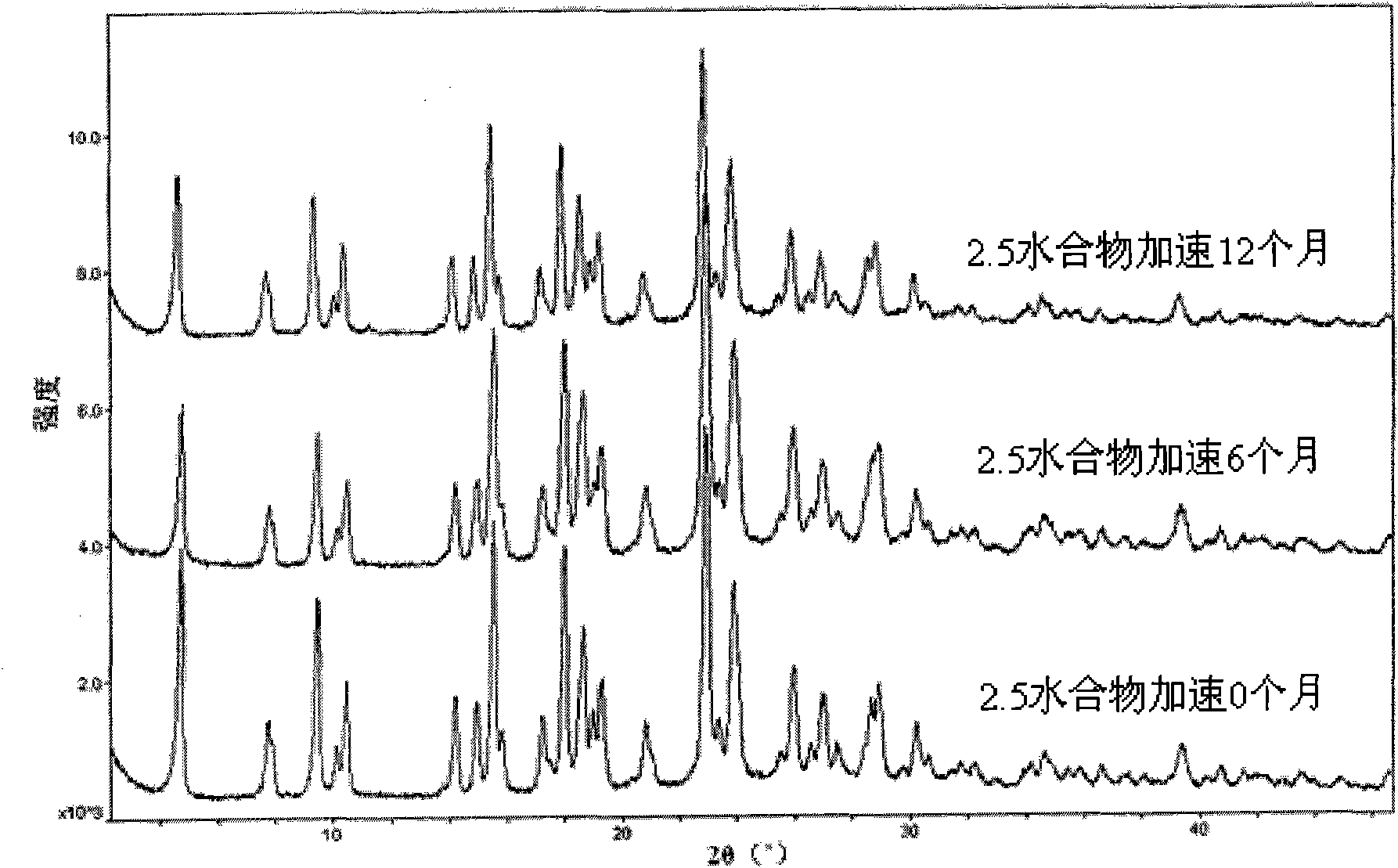

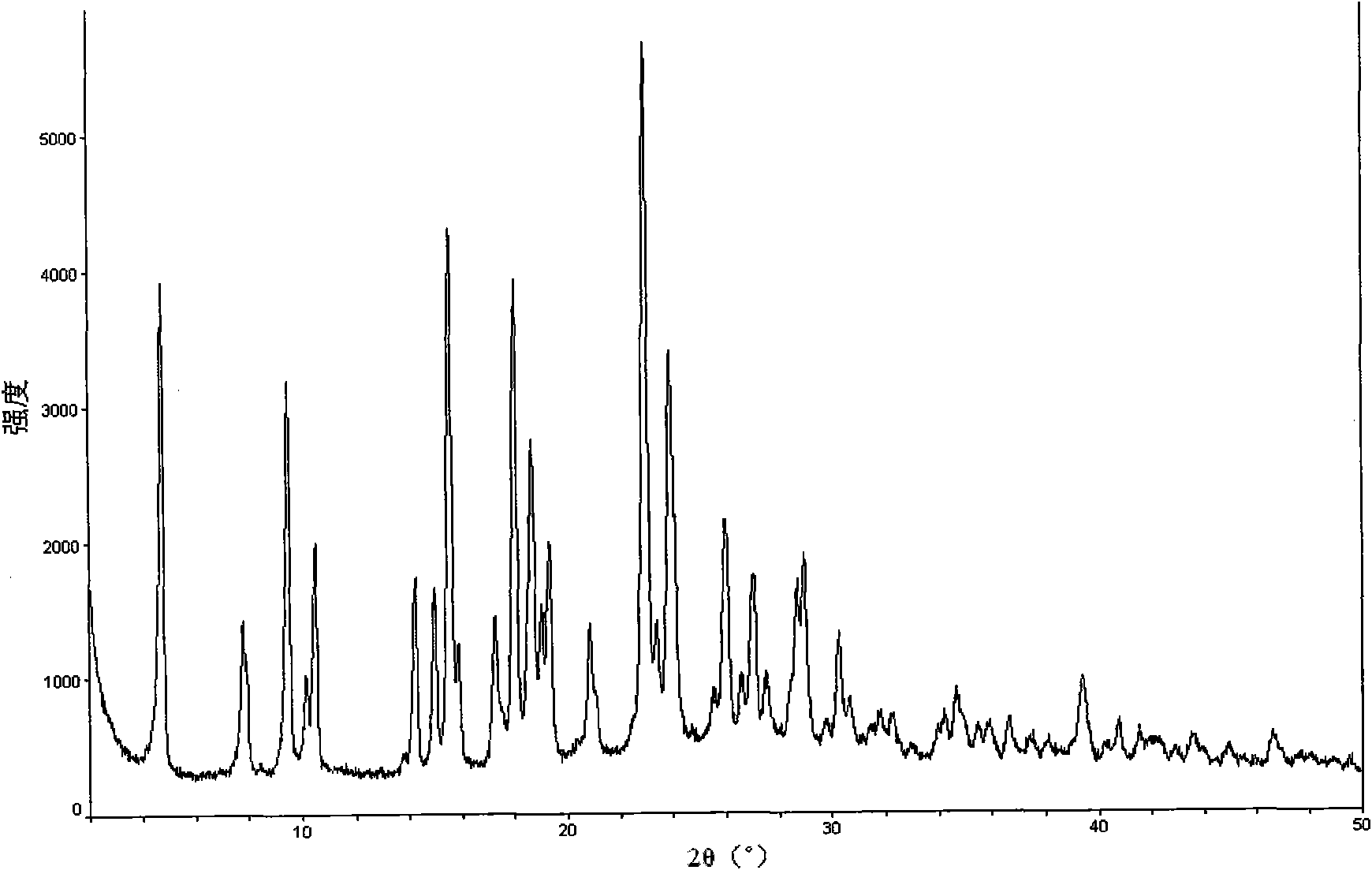

[0027] According to the method stipulated in the Chinese Pharmacopoeia, the obtained product was subjected to accelerated and long-term stability experiments, its water content was regularly measured and its crystal form was analyzed by X-ray powder diffraction. The specific data are shown in Table 1 and Table 2.

[0028] Table 1 Pemetrexed Disodium 2.5 Hydrate Stability Investigation Accelerated Experiment

[0029]

[0030] Table 2 Pemetrexed disodium 2.5 hydrate stability investigation long-term exp...

Embodiment 2

[0036] Add 10 g of pemetrexed disodium into 60 ml of water under argon protection, stir and heat up until the system dissolves;

[0037] Then the aqueous solution was added dropwise to 600ml of isopropanol at room temperature for 1 hour, and after the drop was completed, the temperature was lowered to 10° C. and kept for 1 hour. After filtering, the filter cake was dried under reduced pressure at 50° C. to obtain 9.3 g of pemetrexed disodium 2.5 hydrate.

[0038] Using the same method as in Example 1, the acceleration and long-term stability tests were carried out, and the results were basically the same as in Example 1.

Embodiment 3

[0040] Under the protection of argon, add 10g of pemetrexed disodium into 50ml of water, stir and heat up until the system dissolves; then add the aqueous solution dropwise to 650ml of acetone at room temperature, the dropping time is 1 hour, and cool down after dropping Incubate at 5°C for 1 hour. After filtering, the filter cake was dried under reduced pressure at 50° C. to obtain 9.0 g of pemetrexed disodium 2.5 hydrate. Using the same method as in Example 1, the acceleration and long-term stability tests were carried out, and the results were basically the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com