Method for extracting lead from waste CRT (Cathode Ray Tube) glass

A technology of glass and potassium hydroxide, which is applied in the field of extracting lead and extracting lead from waste CRT glass, can solve the problems of high extraction cost, complex extraction process, unsuitable lead extraction, etc., to reduce environmental impact and promote the application of good industrialization value, the effect of low lead content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

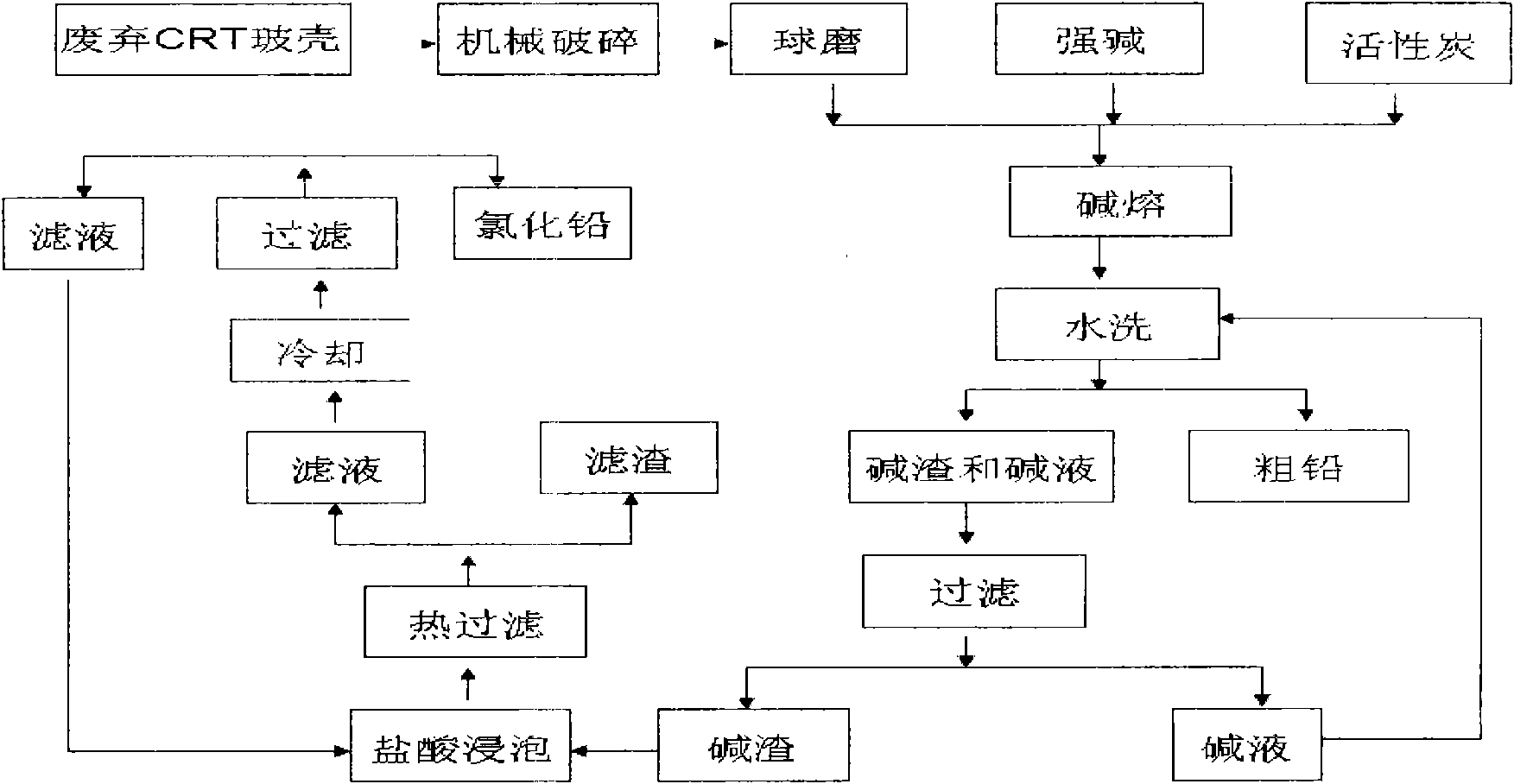

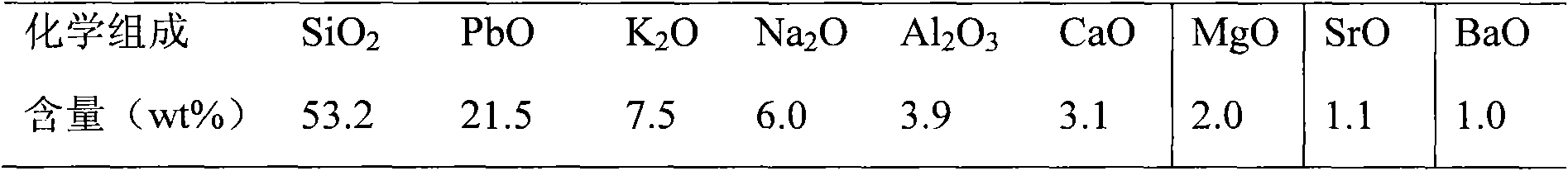

[0022] The glass funnel part in the waste CRT glass was crushed, and then ground to a particle size greater than 100 mesh by a ball mill, and dried in a 105°C drying oven for later use. After analysis, its chemical composition is shown in Table 1.

[0023] The sample chemical composition of CRT glass cone in the embodiment 1 of table 1

[0024]

[0025] A Take 10.177g of glass powder, 10.201g of sodium hydroxide and 0.492g of activated carbon and mix them evenly in a nickel crucible, then add 10.042g of sodium hydroxide to cover the above mixture, place it in a resistance furnace for alkali fusion, and set the alkali fusion temperature to 800℃, alkali melting time 20min, natural cooling after melting;

[0026] B added 50ml of hot water to wash the molten material, the lead precipitated on the bottom layer of the molten material, separated the lead grains, put them in a drying oven to dry, and weighed after the drying was complete, the crude lead weighed 1.805g.

[0027] C...

Embodiment 2

[0029] The neck part of the waste CRT glass is crushed, ground with a ball mill, passed through a 100-mesh sieve, and put into a drying oven at 105°C to dry for later use. After analysis, its chemical composition is as shown in Table 2,

[0030] The sample chemical composition of CRT tube neck in the embodiment 2 of table 2

[0031]

[0032] A Take 9.992g of glass powder, 5.156g of potassium hydroxide and 0.212g of activated carbon and mix them evenly in a nickel crucible, then add 10.742g of potassium hydroxide on the above mixture, put it in a resistance furnace for alkali fusion, and set the temperature at 600°C, Alkali melting time is set to 60min, cooling after melting;

[0033] B adds 50ml of hot water to clean the melt, the lead precipitates on the bottom of the melt, separates the lead grains, puts them in a drying oven to dry, and weighs after the drying is complete, the crude lead weighs 2.824g;

[0034] C filter the alkali slag and lye with fast filter paper, s...

Embodiment 3

[0036] The CRT tube neck is still divided into raw materials for testing,

[0037]A Take 9.961g of glass powder, 19.456g of potassium hydroxide and 0.599g of activated carbon and mix them evenly in a nickel crucible, then add 20.142g of potassium hydroxide to cover the above mixture, put it in a resistance furnace for alkali fusion, and the temperature of alkali fusion is 450 ℃, time 120min, cooling after melting;

[0038] B added 50ml of hot water to clean the melt, separated the lead particles, weighed after drying, and the crude lead weighed 2.815g;

[0039] C filter the alkali slag and lye with fast filter paper, soak the alkali slag in hydrochloric acid with a mass percentage concentration of 10%, place it in a constant temperature water bath, keep the temperature at 95°C, the time is 30min, and the pH value is maintained at less than 3, Then filter while it is hot, and cool to obtain white needle-like PbCl 2 The precipitate was dried and weighed 0.387g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com