Method for preparing photopolymer holographic storage optical disk

A photopolymer, holographic storage technology, applied in optomechanical equipment, photo-engraving process of pattern surface, optics, etc., can solve the problems of poor long-term storage performance, high monomer volatility and high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of perfusate: In a dark room, add 58 grams of propylene glycol diglycidyl ether, 21 grams of N-vinyl carbazole, 0.01 grams of 2,5-bis[4-(diethyl Amino)-benzylidene]cyclopentanone, 0.64 g hexaarylbiimidazole, 0.65 g 4-methyl-4H-1,2,4-triazole-3-thiol, 0.1 g BYK-066, 0.1 g BYK -306, 3 grams of dimethylformamide, mixed thoroughly to form a red transparent solution. Add 16.5 grams of triethylenetetramine to the transparent solution, stir well at room temperature for 10 to 15 minutes to make it evenly mixed, and filter with a filter with a pore size of 0.22 microns to obtain the filtrate after removing particles such as dust in the mixed solution. Put the filtrate into a vacuumable vessel for degassing under reduced pressure, then inject nitrogen gas into the filtrate in the vessel, repeat this operation twice to remove the oxygen and air bubbles in the filtrate to obtain a perfusate, and place it for use.

[0052] Preparation of optical disc molds: take 20 squa...

Embodiment 2

[0056] Adopt following formula, prepare photopolymer type holographic disc by the method for embodiment 1 (see figure 1 left disc).

[0057]

[0058]The difference from Example 1 is that 20 hollow disk-shaped substrates with an inner diameter of 15 mm, an outer diameter of 80 mm, and a thickness of 1 mm were selected for the preparation of the optical disc mold, and 10 hollow disc-shaped substrates with an inner diameter of 15 mm, an outer diameter of 20 mm, and a thickness of 0.5 mm were selected. mm circular small spacers and 10 large circular spacers with an inner diameter of 76mm, an outer diameter of 80mm, and a thickness of 0.5mm. The sheet material is polytetrafluoroethylene, and the filter used is a filter with a pore size of 0.45 microns.

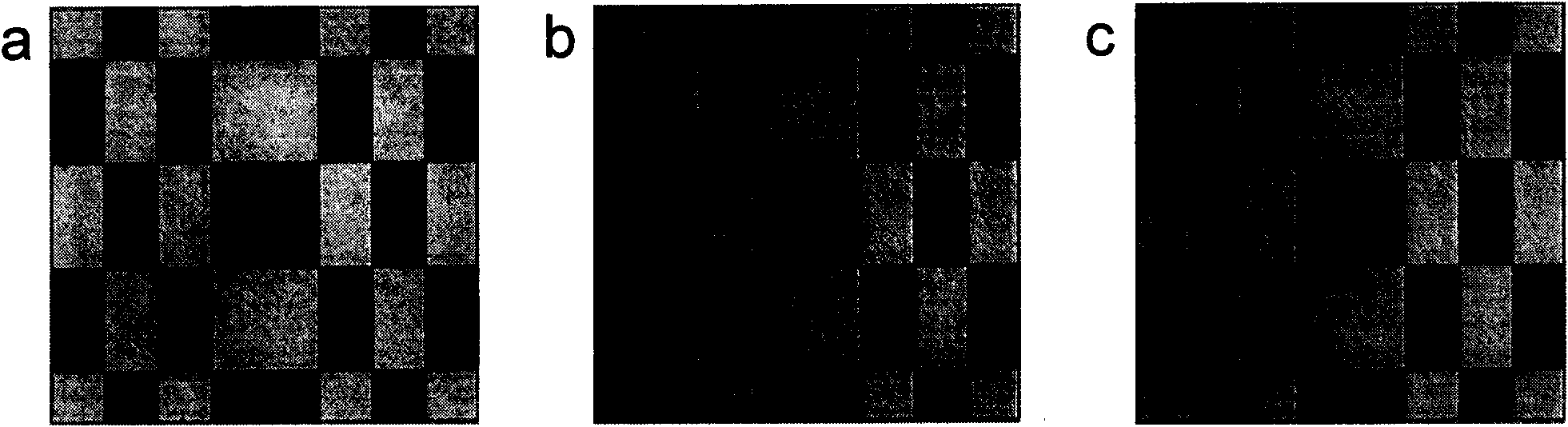

[0059] The use of the disc: use a solid-state laser with a wavelength of 473nm as the light source, and the reference light intensity is 1.5mW / cm 2 , the maximum light intensity of object light is 1.5mW / cm 2 , the angle betwe...

Embodiment 3

[0061] A photopolymer holographic disc was prepared according to the method of Example 1 using the following formula.

[0062]

[0063]

[0064] The difference from Example 1 is that 20 square substrates with a size of 100×100×1.0 (length×width×height, unit: mm) and 10 square substrates with a size of 100×100 (length × width, unit: mm), the inner frame size is 94 × 94 (length × width, unit: mm), and the thickness is 0.4mm. Special B270 optical glass, the material of the gasket is silicone rubber, and the filter used is a filter with a pore size of 0.45 microns.

[0065] The use of the disc: use an argon ion laser with a wavelength of 514nm as the light source, and the reference light intensity is 1.5mW / cm 2 , the maximum light intensity of object light is 1.5mW / cm 2 , the angle between the reference light and the object light is 60 degrees, and the high-density holographic storage of image information can be carried out by changing the position and multiplexing the ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com