Ultrahigh-capacity lithium ion battery anode material prepared by microwave method and preparation method thereof

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult formulation control, long sintering time, irregular particle morphology, etc., achieve excellent electrochemical performance, and improve heat utilization. Efficiency, effect of shortening heat treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

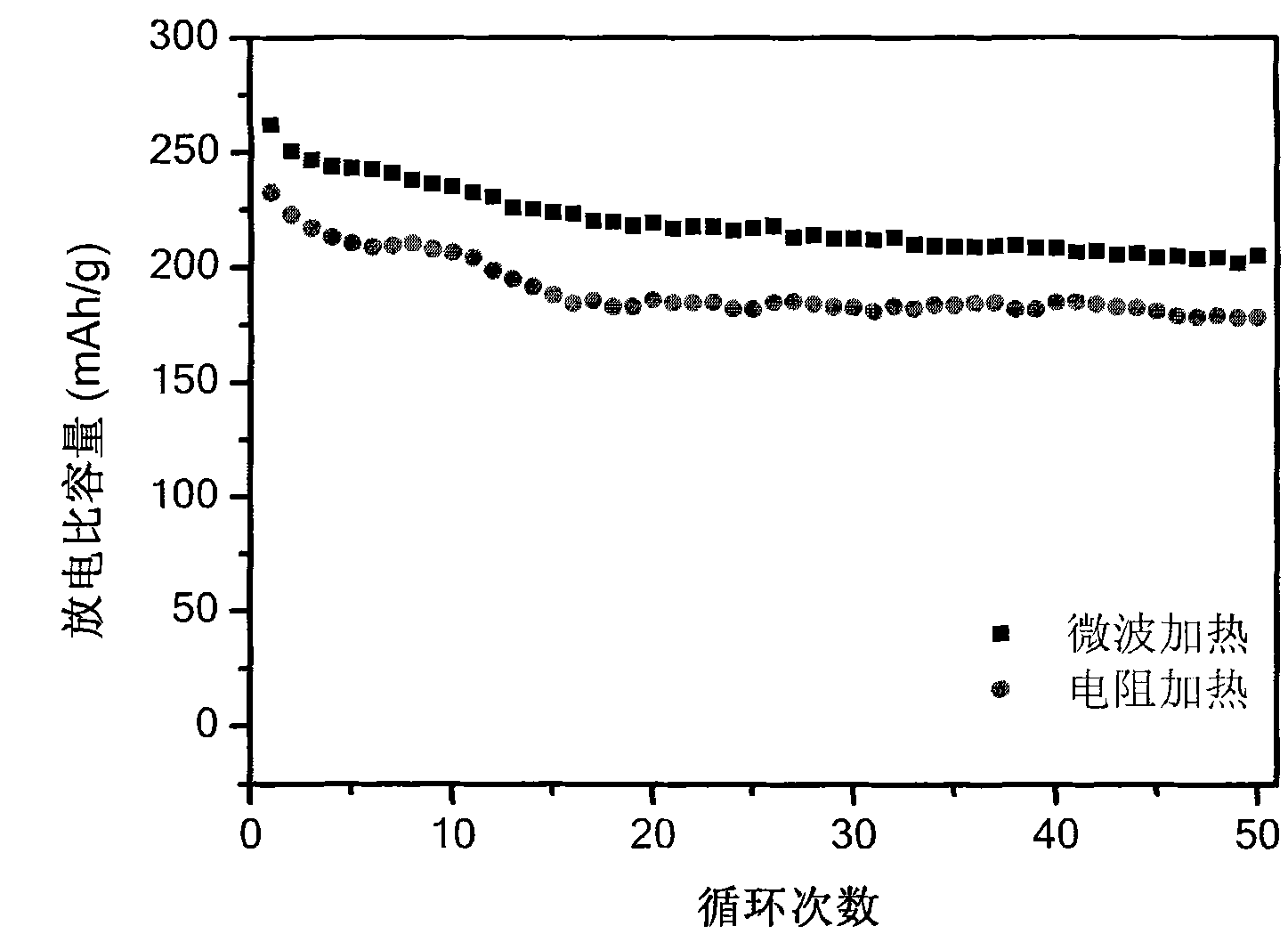

[0021] Lithium hydroxide, oxalic acid, nickel acetate, cobalt acetate, and manganese acetate were mixed in a molar ratio of 1.21:2:0.13:0.13:0.54, and dry ball milling was carried out (the speed was 500rppm, the ball milling time was 3h, and the ball-to-material ratio was 10:1 ). Then the obtained powder was sintered in a microwave air atmosphere furnace at a constant temperature of 400°C for 1h, then sintered at a constant temperature of 800°C for 0.5h, and cooled naturally to room temperature to obtain a layered lithium-rich manganese-based oxide Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 . Lithium hydroxide, oxalic acid, nickel acetate, cobalt acetate, and manganese acetate were mixed in a molar ratio of 1.21:2:0.13:0.13:0.54, and dry ball milling was carried out (the speed was 500rppm, the ball milling time was 3h, and the ball-to-material ratio was 10:1 ). Then the obtained powder was placed in a resistance heating air atmosphere furnace for constant temperature sintering a...

Embodiment 2

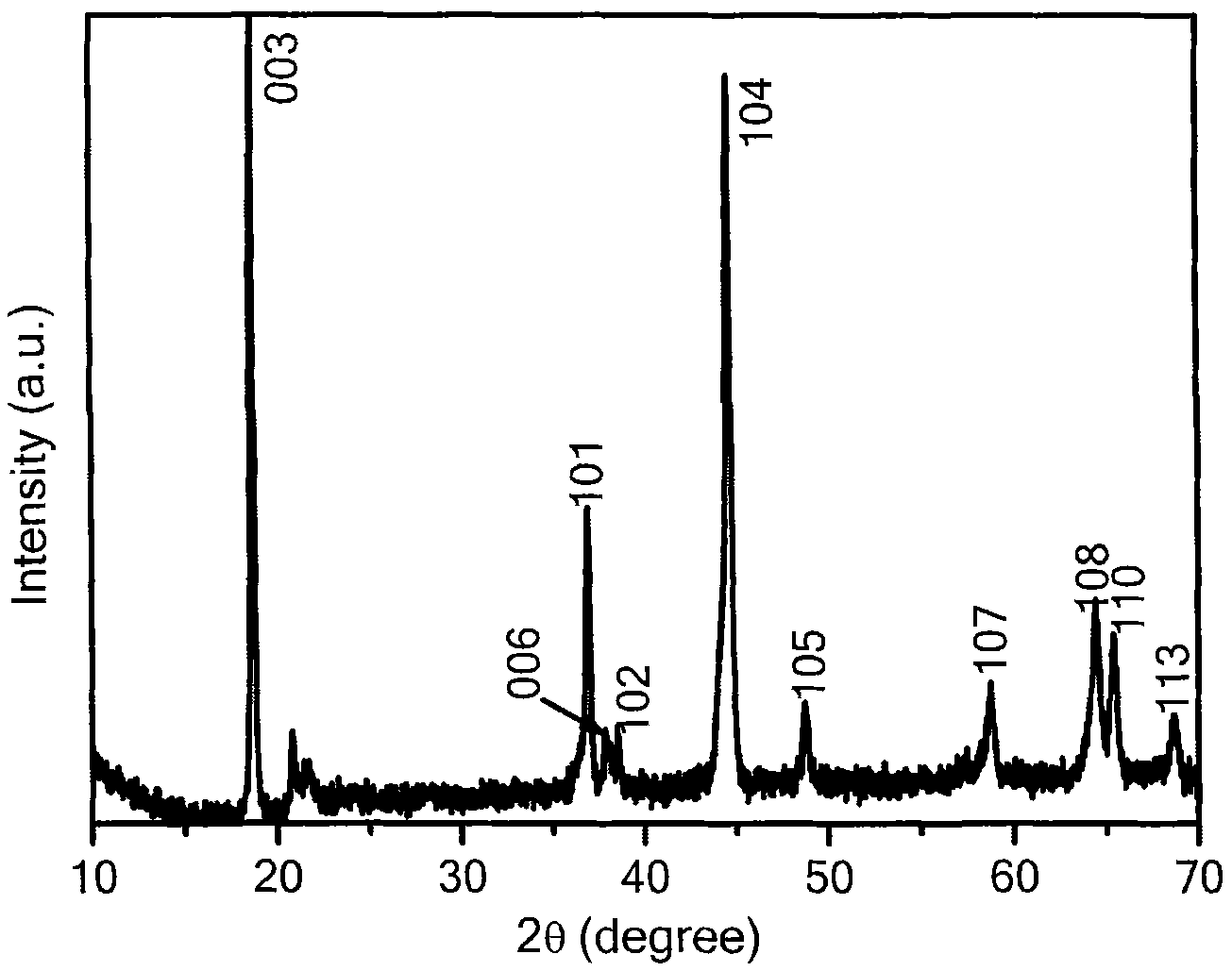

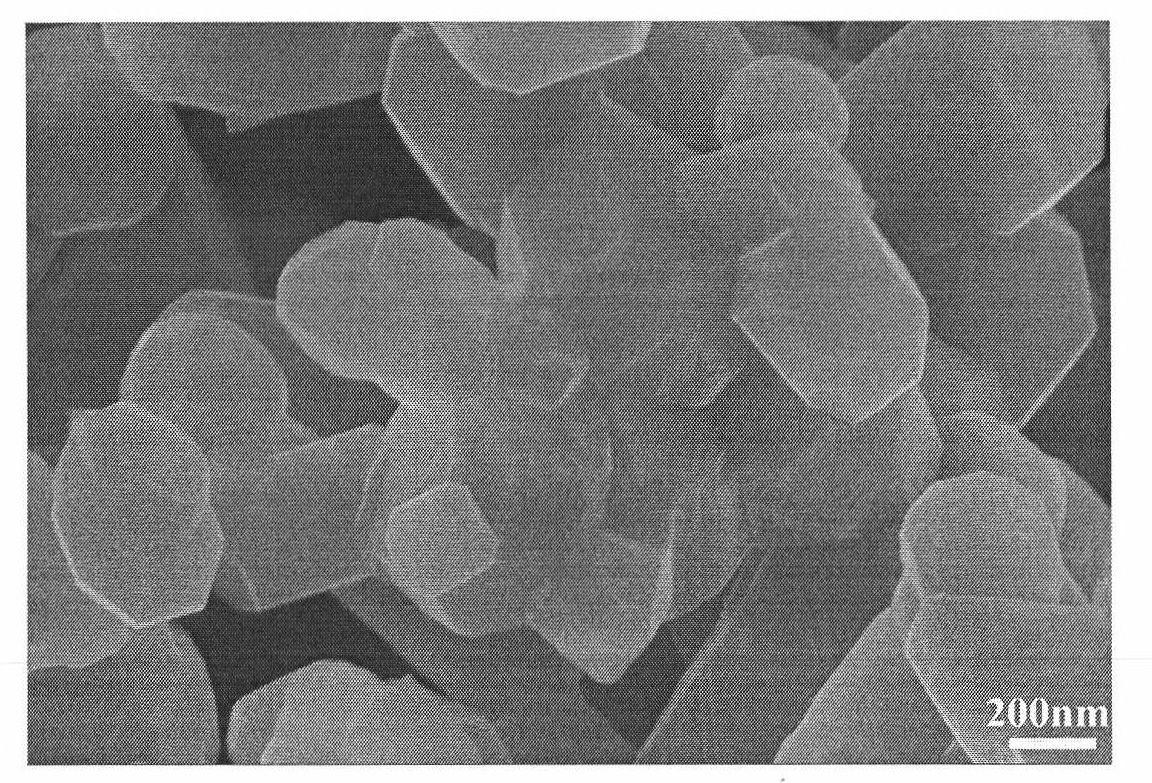

[0023] Lithium hydroxide, oxalic acid, nickel acetate, and manganese acetate were mixed in a molar ratio of 1.21:2:0.2:0.6, and wet ball milled (500rppm speed, 3h ball milling time, 10:1 ball-to-material ratio). Then the obtained powder was sintered in a microwave air atmosphere furnace at a constant temperature of 400°C for 1h, then sintered at a constant temperature of 750°C for 0.5h, and cooled naturally to room temperature to obtain a layered lithium-rich manganese-based oxide Li 1.2 Ni 0.2 mn 0.6 o 2 . The sample has no impurity phase (see attached figure 2 ), uniform particle size distribution (see attached image 3 ), the electrochemical reversible capacity reaches 240mAh / g, and the cycle performance is good.

Embodiment 4

[0025] Lithium carbonate, nickel oxide, and manganese dioxide were mixed in a molar ratio of 0.605:0.2:0.6, and wet ball milled (500rppm rotation speed, 3h ball milling time, 10:1 ball-to-material ratio). Then the obtained powder was sintered in a microwave air atmosphere furnace at a constant temperature of 400°C for 1h, then sintered at a constant temperature of 750°C for 0.5h, and cooled naturally to room temperature to obtain a layered lithium-rich manganese-based oxide Li 1.2 Ni 0.2 mn 0.6 o 2 . The sample has no impurity phase, the electrochemical reversible capacity reaches 230mAh / g, and the cycle performance is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com