Use of composite fast ion conductive film as heat and moisture permeable composite film

An ion-conducting and composite film technology is applied in the field of heat- and moisture-permeable composite films and the preparation thereof, and can solve the problems of no disclosure of the composite fast ion conductive film, no disclosure of the heat and moisture permeability of the composite fast ion conductive film, and the like, and to achieve The effect of low material price and usage, high heat transfer and moisture permeability, and lower product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

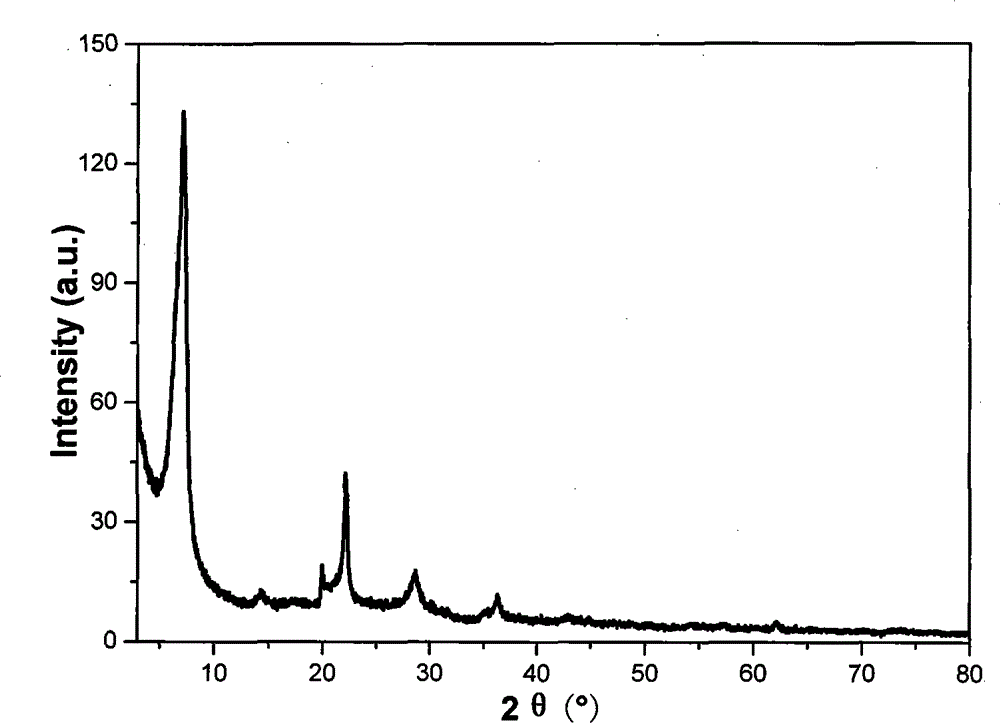

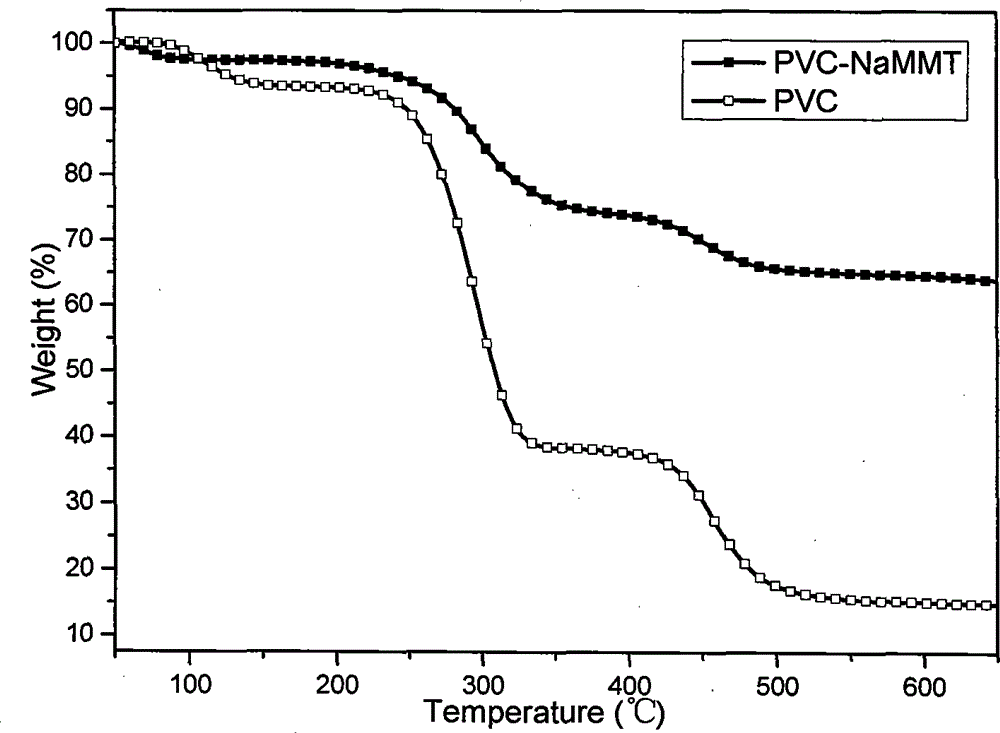

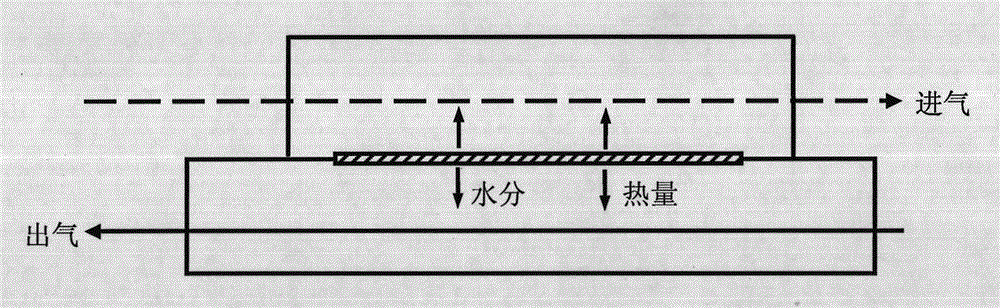

[0025] The heat-permeable and moisture-permeable composite film is composed of polyvinyl chloride and sodium-based montmorillonite, in which the sodium-based montmorillonite is dispersed in polyvinyl chloride as crystal phase powder to form a multi-phase solid film; polyvinyl chloride and sodium-based The mass ratio of montmorillonite is 3:7.

[0026] The preparation method of the above-mentioned composite film is as follows: 3 g of industrial polyvinyl chloride powder is dissolved in 150 mL of tetrahydrofuran organic solvent, and sodium-based montmorillonite is added to the obtained clear liquid, and the mass ratio of polyvinyl chloride powder to sodium-based montmorillonite is 3 : 7; 20 minutes of ultrasonic vibration to make a suspension, cast on a glass plate, and dry to form a self-hanging film; keep it in a blast drying oven at 40°C for half an hour and then peel off the film. The film thickness is 20 μm to 100 μm. The film is soft and can be folded at any angle without ...

Embodiment 2

[0031] The heat-permeable and moisture-permeable composite film is composed of polyvinyl chloride and sodium-based montmorillonite, in which the sodium-based montmorillonite is dispersed in polyvinyl chloride as crystal phase powder to form a multi-phase solid film; polyvinyl chloride and sodium-based The mass ratio of montmorillonite is 4:6.

[0032] The preparation method of the above-mentioned composite film is: take 4g of industrial polyvinyl chloride powder and dissolve it in 150mL of tetrahydrofuran organic solvent, add sodium-based montmorillonite to the obtained clear liquid, and the mass ratio of polyvinyl chloride powder to sodium-based montmorillonite is 4 : 6; ultrasonic vibration for 20 minutes to make a suspension, cast on a glass plate, and dry to form a self-hanging film; keep it in a blast drying oven at 40°C for half an hour and then peel off the film, the film thickness is 20 μm to 100 μm, The film is soft and can be folded at any angle without cracking. Af...

Embodiment 3

[0037] The heat-permeable and moisture-permeable composite film is composed of polyvinyl chloride and sodium-based montmorillonite, in which the sodium-based montmorillonite is dispersed in polyvinyl chloride as crystal phase powder to form a multi-phase solid film; polyvinyl chloride and sodium-based The mass ratio of montmorillonite is 5:5.

[0038] The preparation method of the above-mentioned composite film is as follows: 5 g of industrial polyvinyl chloride powder is dissolved in 150 mL of tetrahydrofuran organic solvent, and sodium-based montmorillonite is added to the obtained clear liquid, and the mass ratio of polyvinyl chloride powder to sodium-based montmorillonite is 5 : 5; 20 minutes of ultrasonic oscillation to make a suspension, cast on a glass plate, and dry to form a self-hanging film; keep it in a blast drying oven at 40°C for half an hour and then peel off the film, the film thickness is 20 μm to 100 μm, The film is soft and can be folded at any angle withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com