Finishing method for improving hydrophilicity of polyester fabric

A polyester fabric and performance technology is applied in the finishing field for improving the hydrophilic properties of polyester fabrics, which can solve the problems of unsuitability for industrialized promotion and use, strong volatility of acrylic monomers, etc., and achieves clean and environmentally friendly treatment methods, improved performance, and comfortable wearing and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

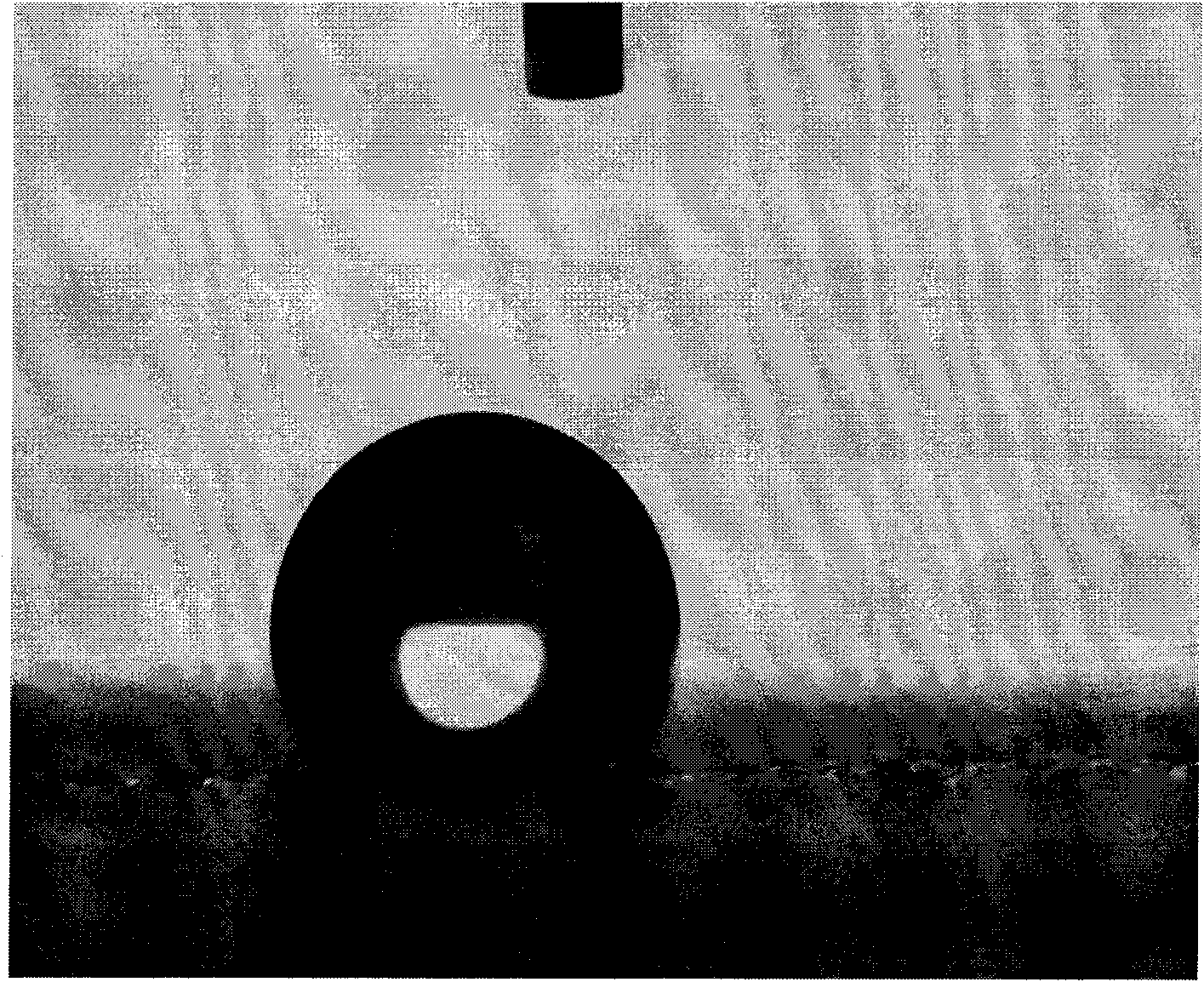

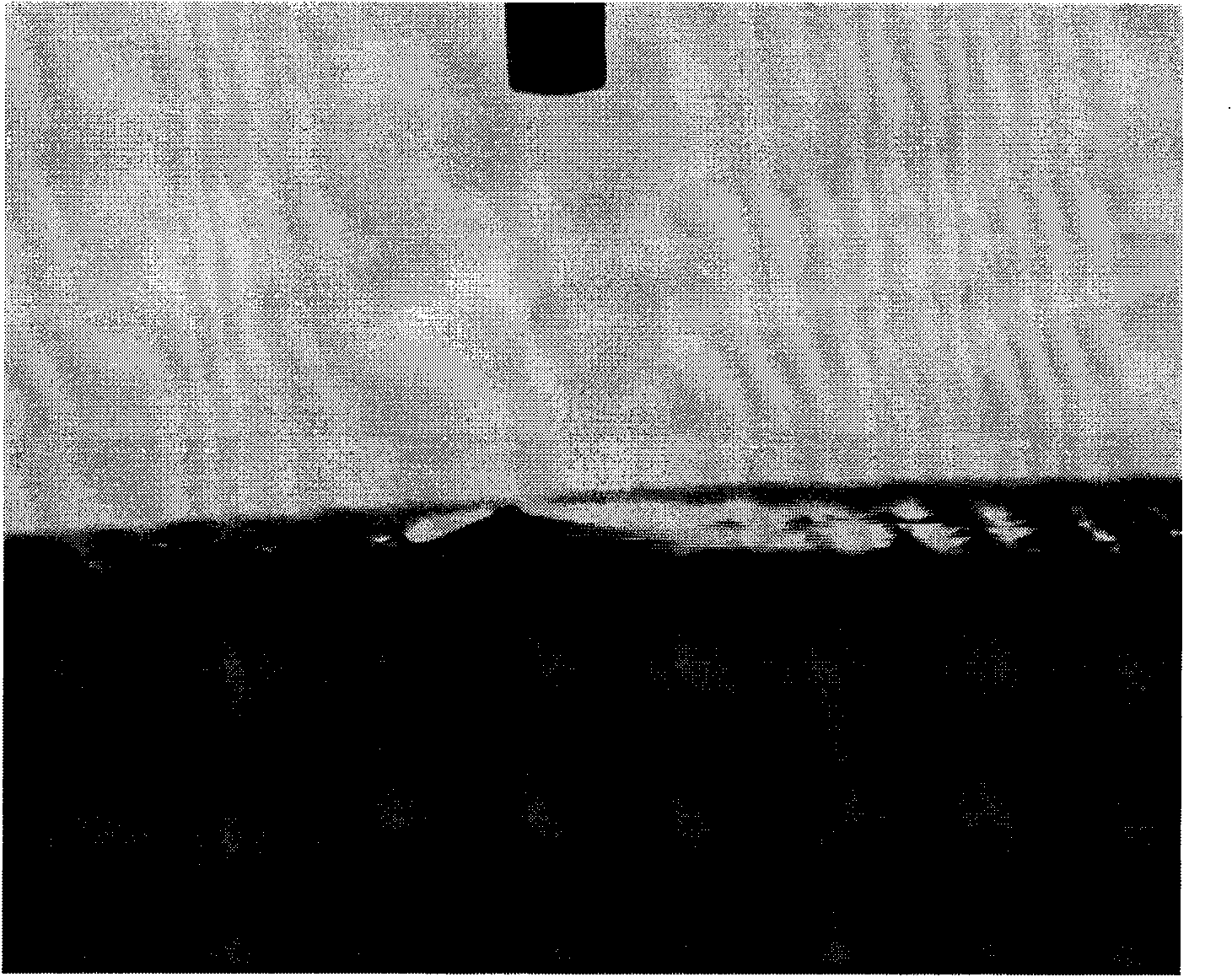

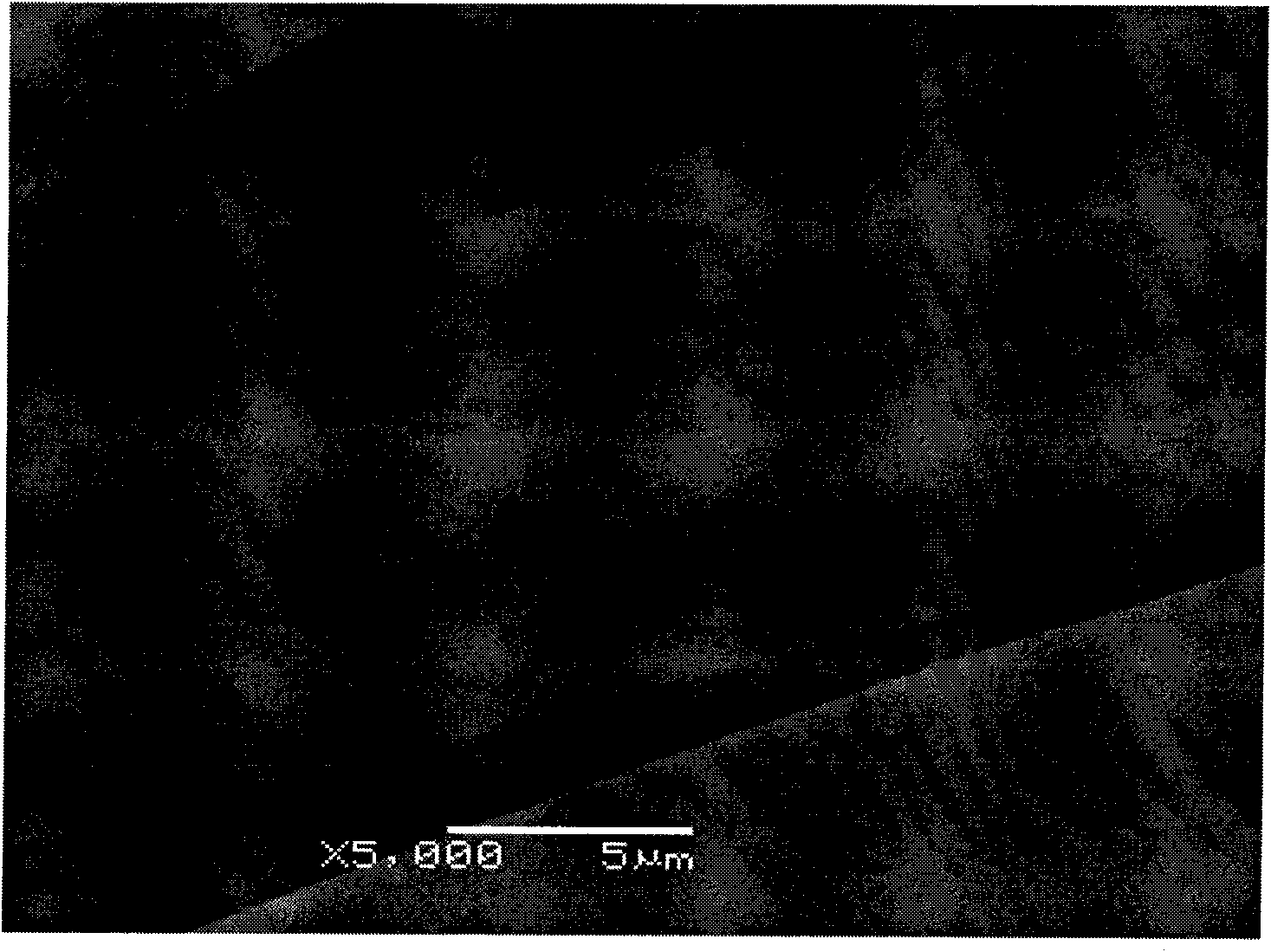

[0041] Implementation process: fabric preparation→dipping graft monomer→grafting treatment→post-treatment→performance test.

[0042] 1) Fabric preparation

[0043] 1# fabric: pure polyester twill fabric 550×340 threads / 10cm, 75D×150D, 150g / cm 2 ;

[0044] 2) Impregnation of grafted monomers

[0045] Grafting monomer: polyethylene glycol 1000, molecular weight 950-1050;

[0046] Impregnation conditions: vibration impregnation, monomer concentration 5%, temperature 25°C, time 1h, bath ratio 1:30;

[0047] Processing equipment: SOT2-24 atmospheric pressure dyeing oscillator, (Dongcheng Dyeing Machinery Factory Co., Ltd.);

[0048] To dry: Air dry naturally.

[0049] 3) Grafting treatment

[0050] Low temperature plasma treatment;

[0051] Processing atmosphere: argon,

[0052] Power: 50W;

[0053] Time: 3min;

[0054] Vacuum degree: 30Pa;

[0055] Processing equipment: HD-2 cold plasma modification equipment (Changzhou Shitai Plasma Technology Development Co., Ltd.).

...

Embodiment 2

[0077] Implementation process: fabric preparation→dipping graft monomer→grafting treatment→post-treatment→performance test.

[0078] 1) Fabric preparation

[0079] 2# fabric: pure polyester plain weave fabric 690×500 / 10cm, 50D / 96f, 100g / cm 2 .

[0080] 2) Impregnation of grafted monomers

[0081] Grafting monomer: polyethylene glycol 1000, molecular weight 950-1050;

[0082] Impregnation conditions: vibration impregnation, monomer concentration 5%, temperature 25°C, time 1h, bath ratio 1:30;

[0083] Processing equipment: SOT2-24 atmospheric pressure dyeing oscillator, (Dongcheng Dyeing Machinery Factory Co., Ltd.);

[0084] To dry: Air dry naturally.

[0085] 3) Grafting treatment

[0086] Low temperature plasma treatment;

[0087] Processing atmosphere: argon,

[0088] Power: 100W;

[0089] Time: 2min;

[0090] Vacuum degree: 30Pa;

[0091] Processing equipment: HD-2 cold plasma modification equipment (Changzhou Shitai Plasma Technology Development Co., Ltd.).

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com