Polydiethylene glycol succinate quartz capillary column and preparation method thereof

A quartz capillary and polysuccinate technology, which is applied in the field of chromatographic separation column and analytical chemistry, can solve the problems of limited use length, separation effect of packed chromatographic column, service life not as good as that of quartz capillary column, poor permeability of packed chromatographic column, etc. Achieve the effect of long service life, low cost and strong separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

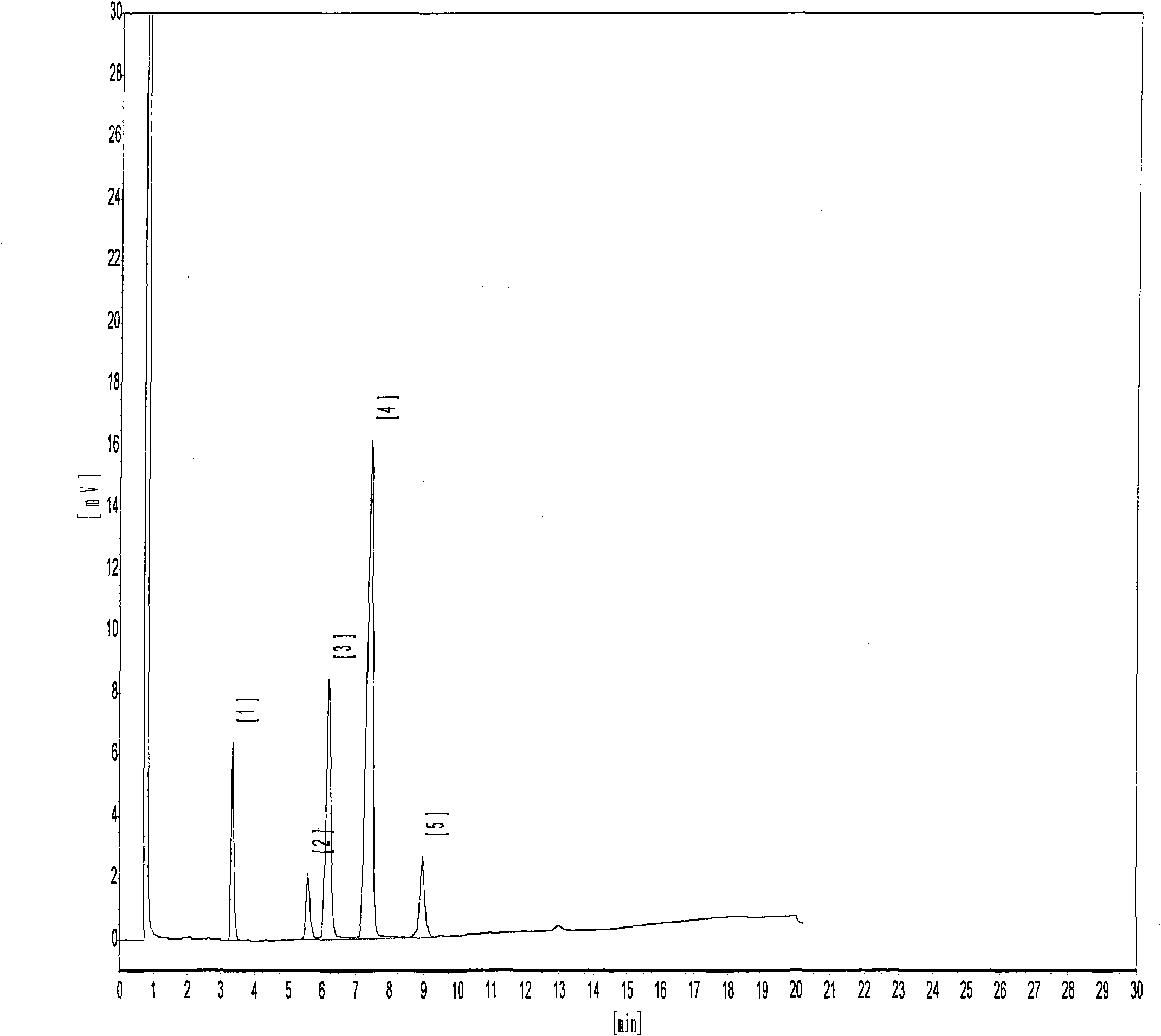

Embodiment 1

[0017] (1) Take a commercially available quartz capillary tube with an inner diameter of 0.32 mm and a length of 30 m, put it in an aging box, pass nitrogen gas through the tube, keep it at 280°C for 2 hours, and then take out the column tube after cooling down to room temperature, and insert a silicone rubber pad at both ports Sealed for later use.

[0018] (2) Weigh 90 mg of diethylene glycol polysuccinate stationary phase and 10 mg of polyethylene glycol stationary phase with a 25 mL volumetric flask. Then add diethyl ether and dichloromethane with a volume ratio of 2:1 in a mixed solvent to dissolve, and set to volume for later use.

[0019] (3) Use high-pressure homogenizer to fill the fixed liquid into the pretreated quartz capillary empty column, seal one end of the chromatographic column with a silicone rubber gasket, put the chromatographic column as a whole in a constant temperature water bath at 25°C, and connect the other end to the The solvent was evaporated in t...

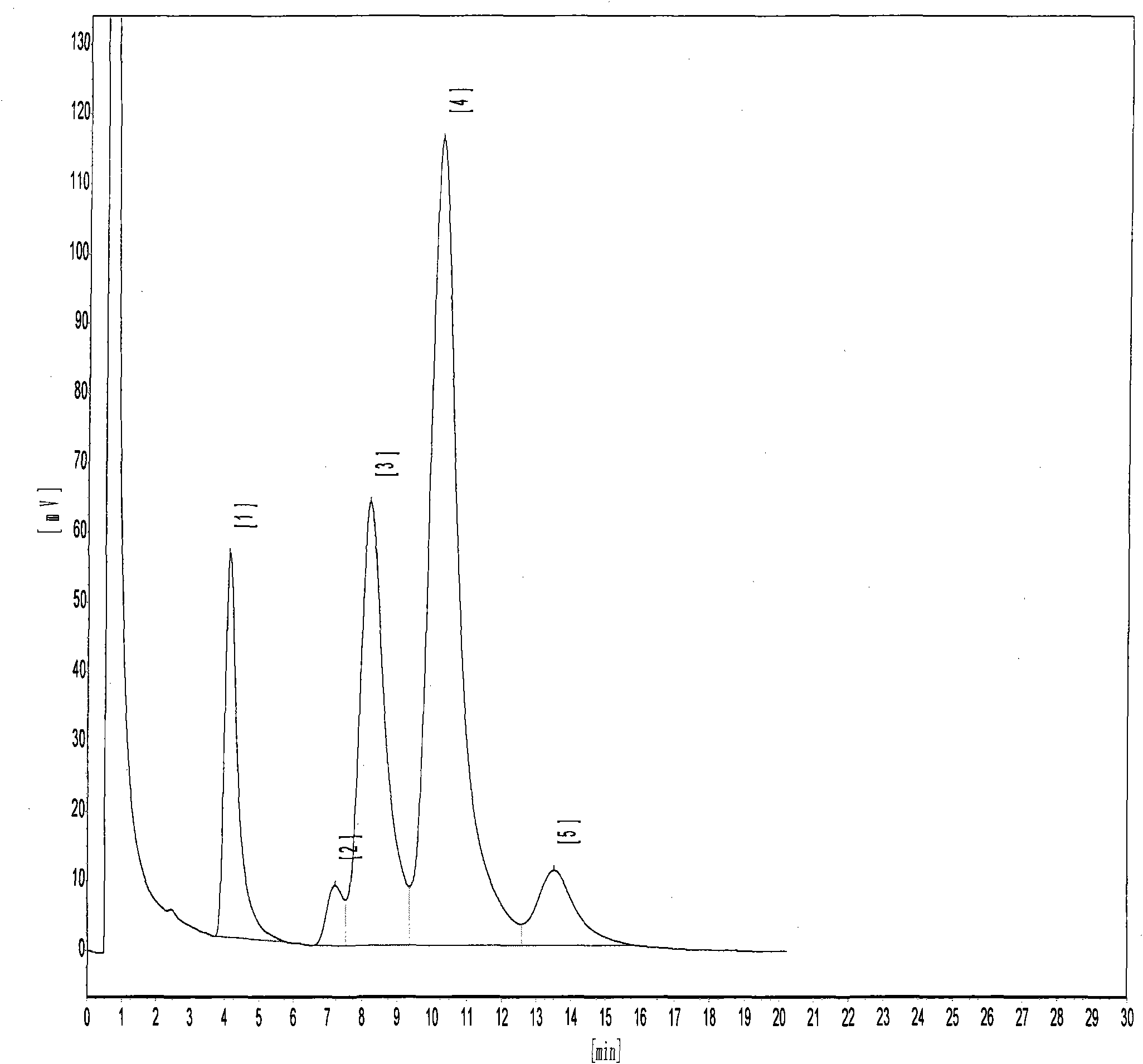

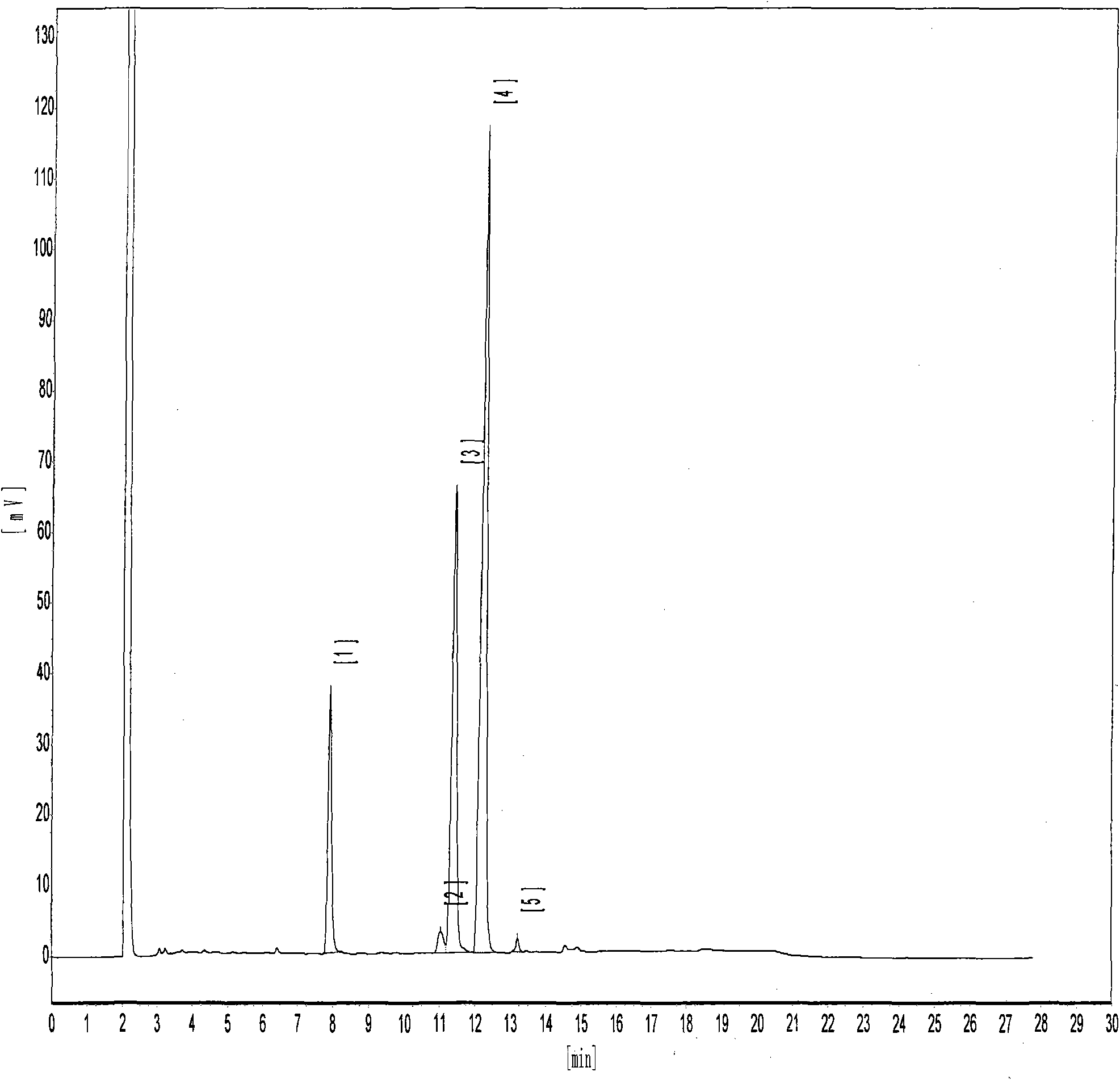

Embodiment 2

[0023] (1) Take a commercially available quartz capillary tube with an inner diameter of 0.32 mm and a length of 30 m, put it in an aging box, pass nitrogen gas through the tube, keep it at 280°C for 2 hours, and then take out the column tube after cooling down to room temperature, and insert a silicone rubber pad at both ports Sealed for later use.

[0024] (2) Weigh 90 mg of diethylene glycol polysuccinate stationary phase and 10 mg of polyethylene glycol stationary phase with a 50 mL volumetric flask. Then add diethyl ether and dichloromethane with a volume ratio of 2:1 in a mixed solvent to dissolve, and set to volume for later use.

[0025] (3) Use high-pressure homogenizer to fill the fixed liquid into the pretreated quartz capillary empty column, seal one end of the chromatographic column with a silicone rubber gasket, put the chromatographic column as a whole in a constant temperature water bath at 25°C, and connect the other end to the The solvent was evaporated in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com