Topological insulator material and preparation method thereof

A technology of topological insulator and deposition method, applied in insulators, inorganic insulators, electrolytic inorganic material coating and other directions, can solve problems such as unreported, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1. Preparation of Single Crystal Antimony Telluride / Turium Segmented Nanowire Arrays

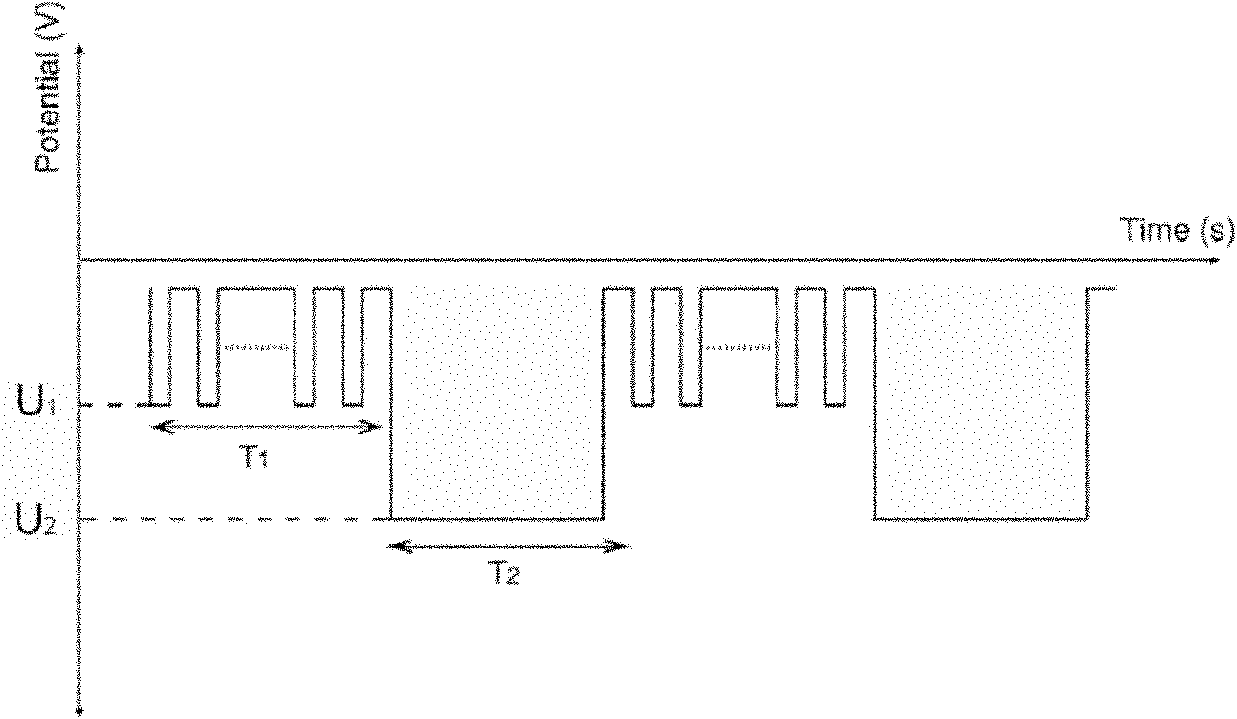

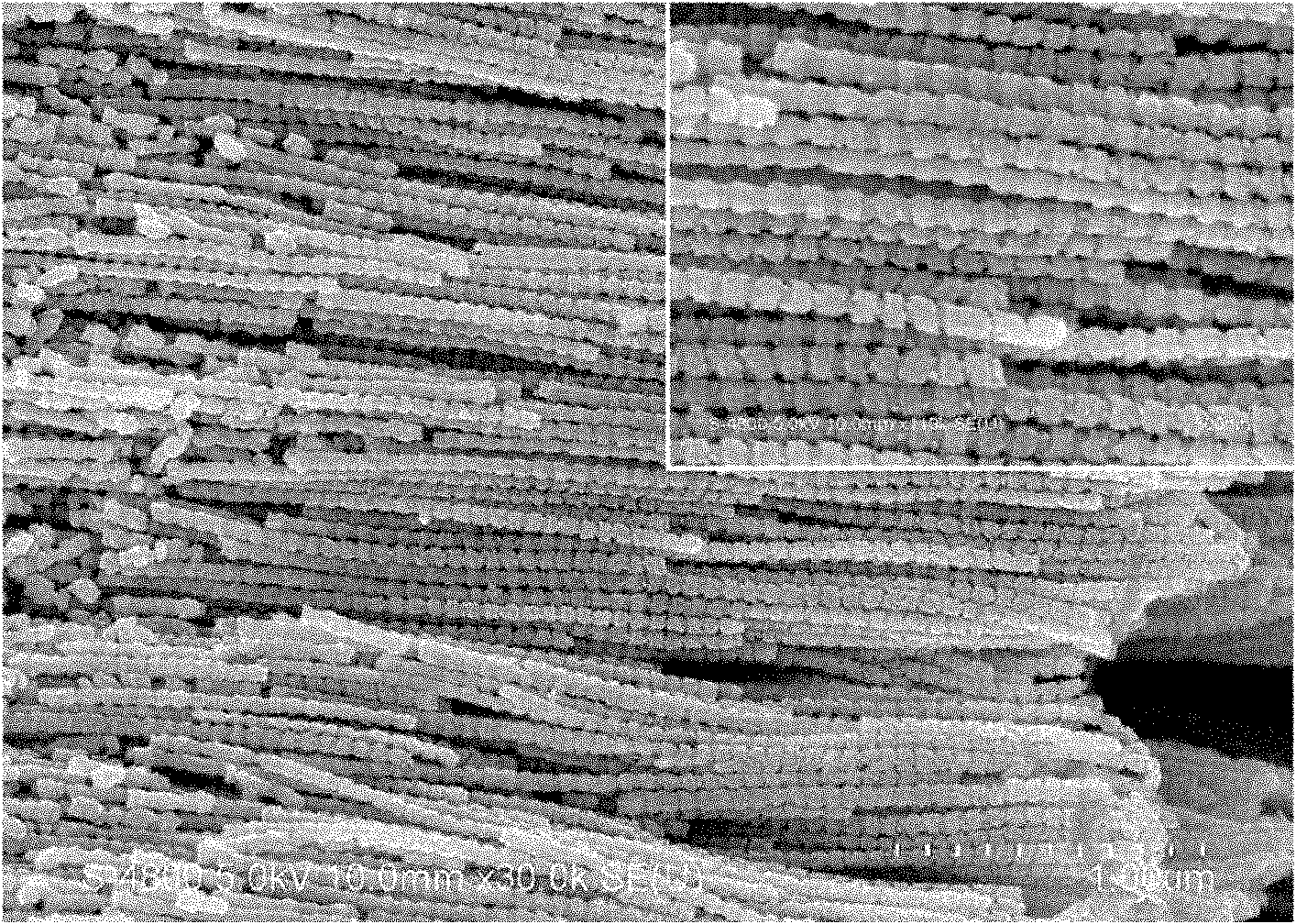

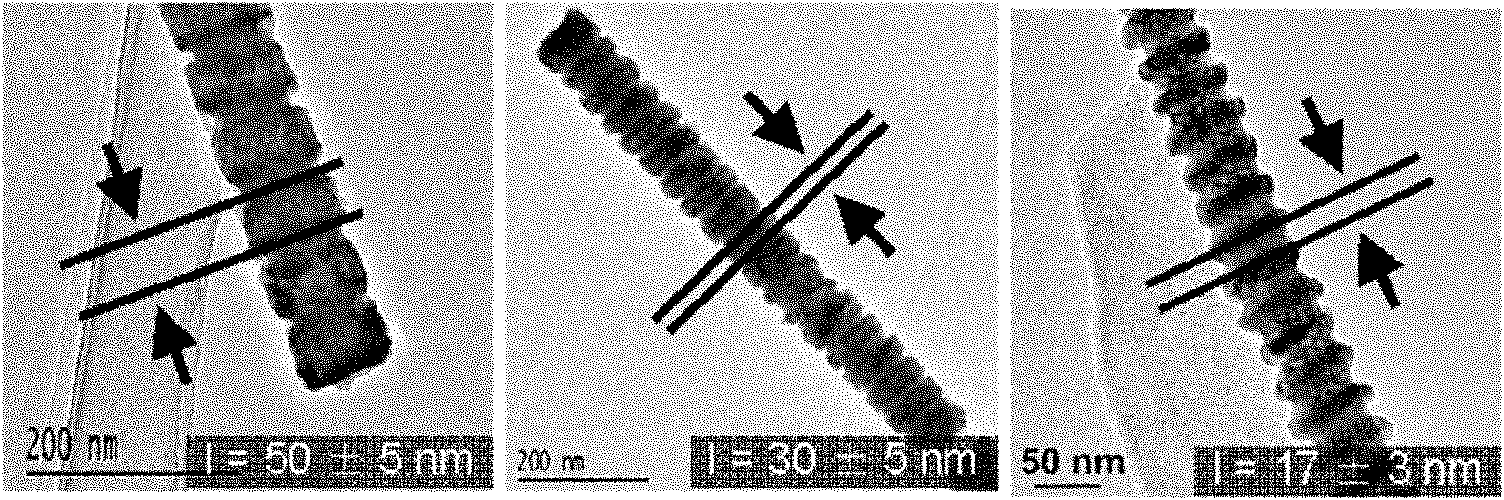

[0029] A 50nm-thick gold film on the back, an alumina template with a length and width of about 1 cm, and a thickness of 30 microns was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. The concentrations were 0.005mol / The mixed solution of L and 0.015mol / L antimony trioxide and tellurium dioxide nitric acid (1mol / L) and tartaric acid (0.8mol / L) and water is the electrolyte, and the deposition is carried out under the conditions of two different deposition behaviors. Antimony telluride or tellurium, the voltages of the two stages are -0.35V and -0.70V respectively, T 1 :T 2 =3:1, where T 1 Consists of 6 voltage pulses. The electrolyte should be stirred at a constant speed during the 3-hour deposition process. After the electrochemical deposition is finished, a layer...

Embodiment 2

[0030] Example 2. Preparation of single crystal antimony telluride / tellurium segmented nanowire arrays

[0031] A 50nm-thick gold film on the back, an alumina template with a length and width of about 1 cm, and a thickness of 30 microns was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. The concentrations were 0.005mol / The mixed solution of L and 0.015mol / L antimony trioxide and tellurium dioxide nitric acid (1mol / L) and tartaric acid (0.8mol / L) and water is the electrolyte, and the deposition is carried out under the conditions of two different deposition behaviors. Antimony telluride or tellurium, the voltages of the two stages are -0.20V and -0.35V respectively, T 1 :T 2 =4:1, where T 1 Consists of 3 voltage pulses. The electrolyte should be stirred at a constant speed during the 3-hour deposition process. After the electrochemical deposition is finished, a la...

Embodiment 3

[0032] Example 3, preparation of single crystal tellurium nanodiscs

[0033] A 50nm-thick gold film on the back, an alumina template with a length and width of about 1 cm, and a thickness of 30 microns was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. The concentrations were 0.005mol / The mixed solution of L and 0.015mol / L antimony trioxide and tellurium dioxide nitric acid (1mol / L) and tartaric acid (0.8mol / L) and water is the electrolyte, and the deposition is carried out under the conditions of two different deposition behaviors. Antimony telluride or tellurium, the voltages of the two stages are -0.20V and -0.70V respectively, T 1 :T 2 =1:1, where T 1 Consists of 2 voltage pulses. The electrolyte should be stirred at a constant speed during the 3-hour deposition process. After the electrochemical deposition, the interior of the aluminum oxide template was uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com