Electrodeless fluorescent lamp

A technology for electrodeless fluorescent lamps and lamp tubes, which is applied in the direction of discharge lamps, parts of gas discharge lamps, electrical components, etc., which can solve the problems of reducing the amount of fluorescent light, increasing the temperature of magnets, and conducting interference, and achieving the reduction of bridging and sealing. process, reduce the temperature of the coupler, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

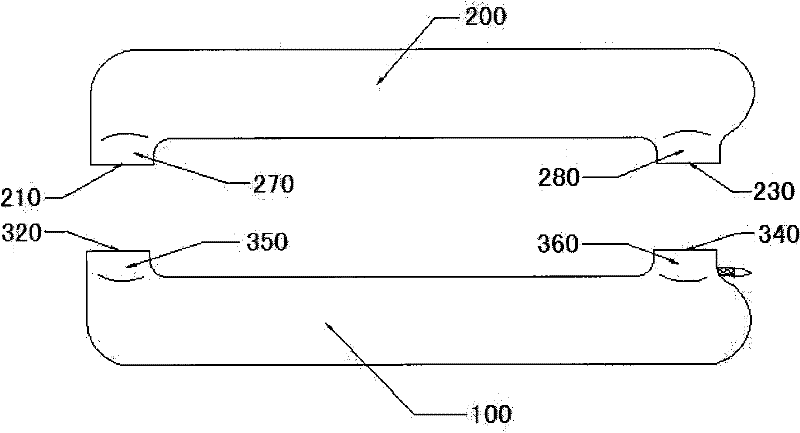

[0074] see Image 6 with Figure 7 , the whole lamp tube includes two U-shaped glass lamp tubes 600 and 700 welded together, three primary color phosphors 2 are attached to the inner tube walls of the glass lamp tubes 600 and 700, and the two ends of the glass lamp tube 600 are bent into the second A sensing surface 610 and a second sensing surface 620. An exhaust glass tube 650 is arranged in the glass lamp tube 600. The exhaust glass tube 650 is also used to place the indium mesh 660, corresponding to the first sensing surface 610 and the second sensing surface 620. There is a first welding surface 630 and a second welding surface 640 . The two ends of the glass lamp tube 700 are bent into a third sensing surface 710 and a fourth sensing surface 720, a bent glass tube 750 is arranged inside the glass lamp tube 700, an amalgam 760 is placed inside the bent glass tube 750, and the bent The glass tube 750 can prevent the amalgam 760 from flowing backward, and the third sensin...

Embodiment 2

[0077] see Figure 8 , the whole lamp tube is composed of a U-shaped glass lamp tube 600, three primary color phosphors 2 are attached to the inner tube wall of the glass lamp tube 600, and exhaust glass tubes 650 and folding Bent glass tube 750, an induction body 830 is arranged between the two ends of the glass lamp tube 600, the exhaust glass tube 650 is used to place indium mesh 660 at the same time, amalgam 760 is placed in the bent glass tube 750, and the bent glass tube 750 It can prevent the amalgam 760 from flowing backward. A power coupler (not shown in the figure) is installed on the inductor 830 . In order to maintain sufficient power of the lamp when the lamp works at low temperature for a long time, a thermal sleeve 761 is placed on the amalgam 760 of the bent glass tube 750, so that the power will be stable when the lamp works at low temperature for a long time.

Embodiment 3

[0079] see Figure 9 , the whole tube consists of a semi-curved Type 600 glass tube and a semi-bent inverted Type glass lamp tube 700 is welded, on the inner wall of the glass lamp tubes 600 and 700, three primary color phosphors 2 are attached, and the two ends of the glass lamp tube 600 are bent into a first sensing surface 610 and a second sensing surface 620 There is an exhaust glass tube 650 inside the glass lamp tube 600, the exhaust glass tube 650 is also used to place the indium mesh 660, and the welding surfaces corresponding to the first sensing surface 610 and the second sensing surface 620 are flat. The two ends of the glass lamp tube 700 are bent into a third sensing surface 710 and a fourth sensing surface 720, a bent glass tube 750 is arranged inside the glass lamp tube 700, an amalgam 760 is placed inside the bent glass tube 750, and the bent The glass tube 750 can prevent the amalgam 760 from flowing backward, and the welding surfaces corresponding to the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com