Silicon-based double-junction solar cell with homojunction and heterojunction and preparation method thereof

A solar cell and homojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as high manufacturing costs, high requirements for process parameter control, and attenuation of battery efficiency, and achieve cost-effective and simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

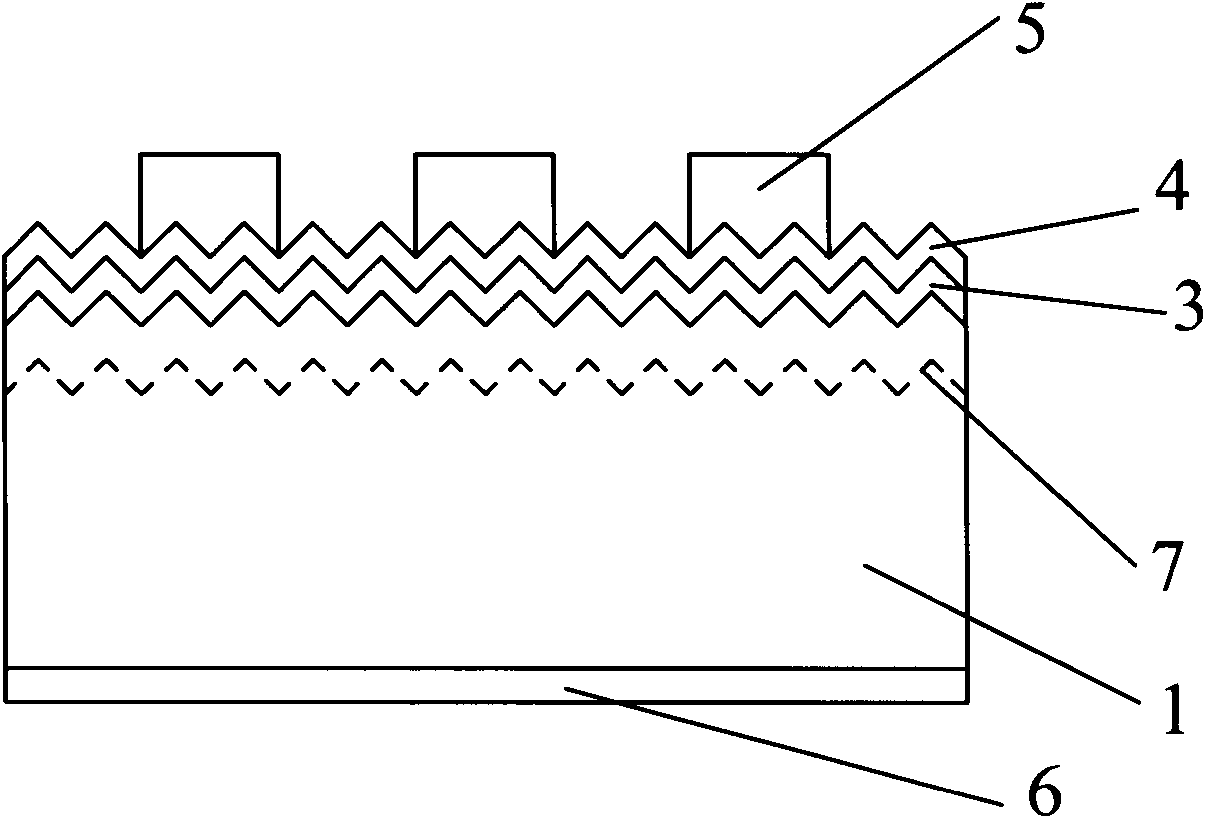

[0036] Such as figure 1 The front side of the P-type polysilicon wafer shown is a double-junction battery with a PN junction. The double-junction battery includes a P-type polysilicon wafer. The front side of the P-type polysilicon wafer forms a homogeneous PN junction. + type amorphous silicon film, N + An ITO transparent conductive film is arranged on the top of the non-crystalline silicon film, and a front metal electrode and a back metal electrode are respectively arranged on the top of the ITO transparent conductive film and the back of the polycrystalline silicon wafer.

[0037] figure 1 The reference signs in are as follows: 1, P-type polysilicon chip, 3, N + Type amorphous silicon film, 4. ITO transparent conductive film, 5. Front metal electrode, 6. Back metal electrode, 7. Homogeneous PN junction.

[0038] The preparation process of the above-mentioned double-junction cell with a PN junction on the front side of the P-type polysilicon wafer is as follows:

[00...

Embodiment 2

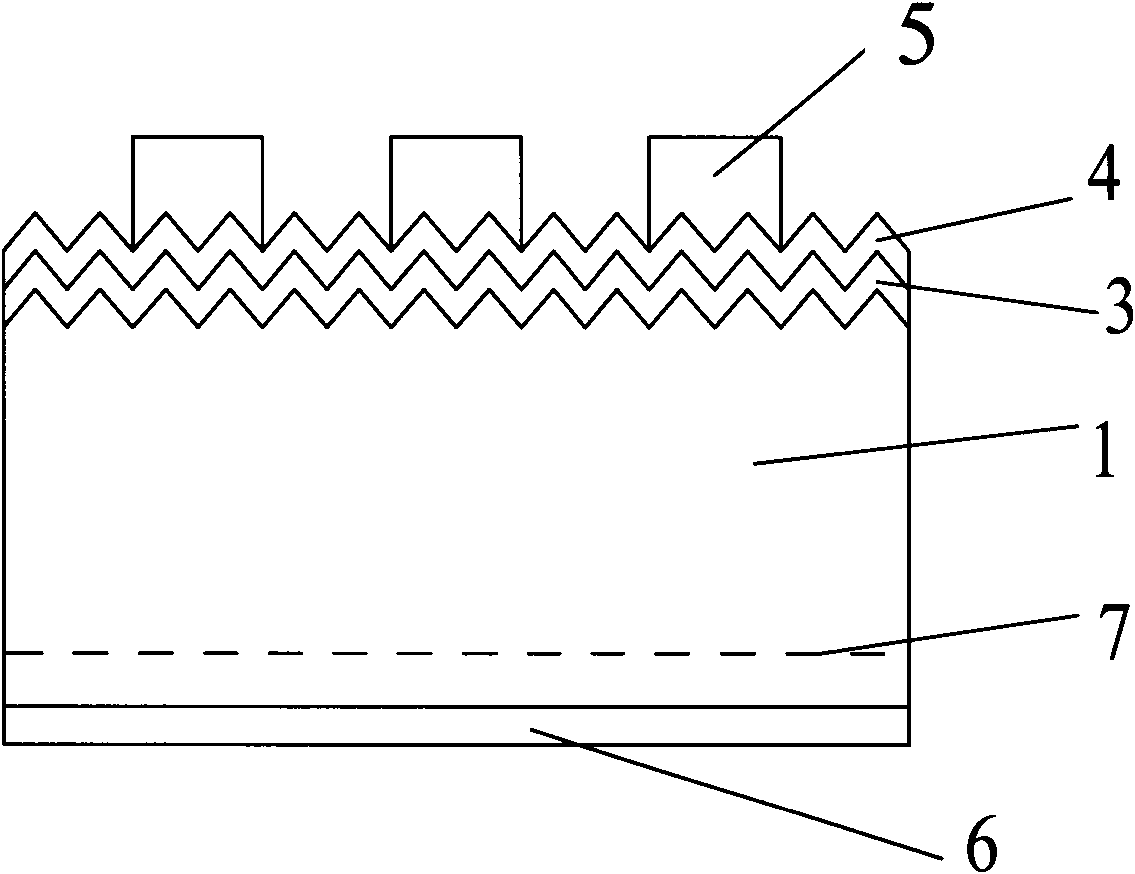

[0043] Such as figure 2 The back of the P-type single crystal silicon wafer shown is a double-junction battery with a PN junction. The double-junction battery includes a P-type single crystal silicon wafer. The upper side of the sheet is provided with a P + type amorphous silicon film, P + An ITO transparent conductive film is arranged on the top of the amorphous silicon film, and a front metal electrode and a back metal electrode are respectively arranged on the top of the ITO transparent conductive film and the back of the single crystal silicon wafer.

[0044] figure 2 The reference signs in are as follows: 1, P-type monocrystalline silicon wafer, 3, P + Type amorphous silicon film, 4. ITO transparent conductive film, 5. Front metal electrode, 6. Back metal electrode, 7. Homogeneous PN junction.

[0045] The preparation process of the above-mentioned double-junction cell with a PN junction on the back side of the P-type single crystal silicon wafer is as follows:

[...

Embodiment 3

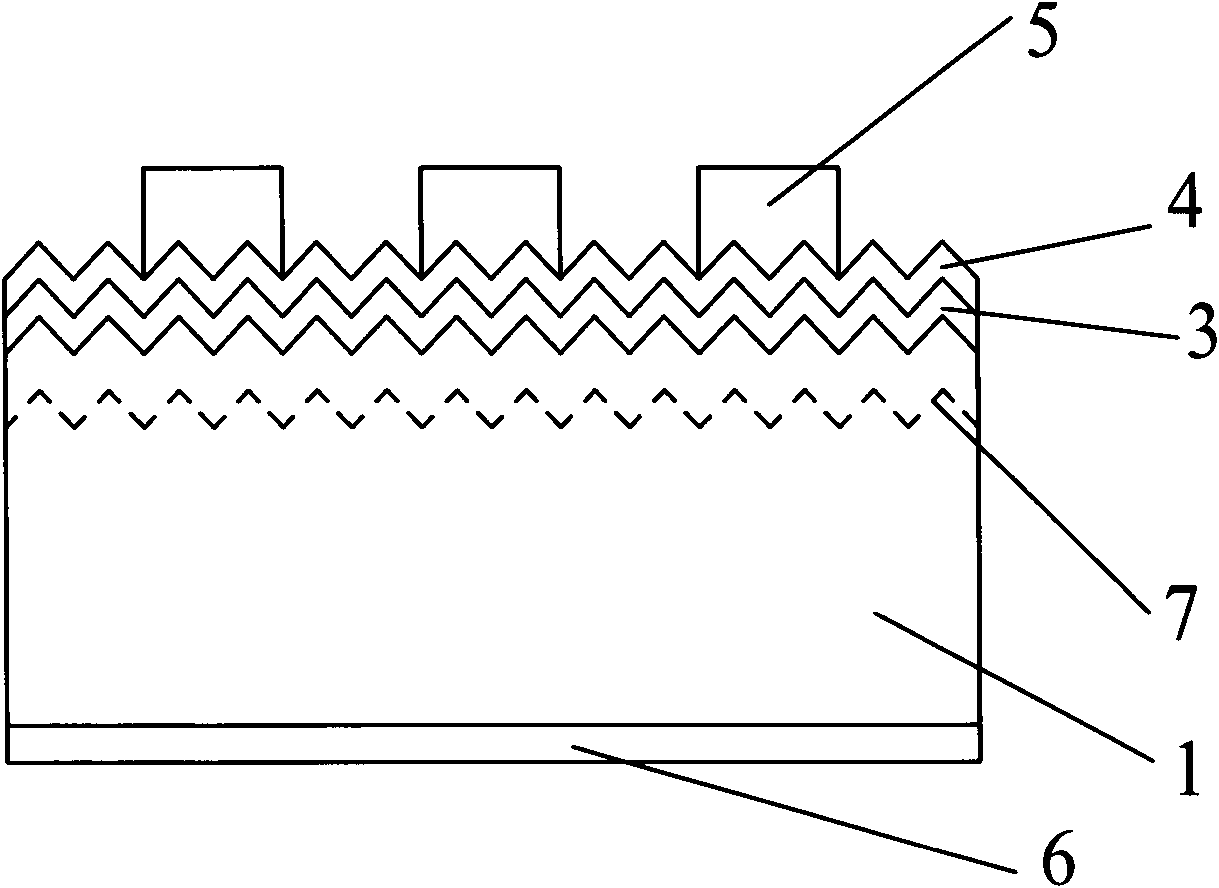

[0050] Such as image 3 The front side of the N-type single crystal silicon wafer shown is a double-junction battery with a PN junction. The double-junction battery includes an N-type single crystal silicon wafer. The front of the N-type single crystal silicon wafer forms a homogeneous PN junction. There is a P on the top of the front + type amorphous silicon film, P + An ITO transparent conductive film is arranged on the top of the amorphous silicon film, and a front metal electrode and a back metal electrode are respectively arranged on the top of the ITO transparent conductive film and the back of the single crystal silicon wafer.

[0051] image 3 The reference signs in are as follows: 1, N-type monocrystalline silicon wafer, 3, P + Type amorphous silicon film, 4. ITO transparent conductive film, 5. Front metal electrode, 6. Back metal electrode, 7. Homogeneous PN junction.

[0052] The preparation process of the above-mentioned double-junction cell with a PN junction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com