Preparation method of rare-earth composite oxide photocatalyst

A photocatalyst and rare earth composite technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve good catalytic activity, mild reaction conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

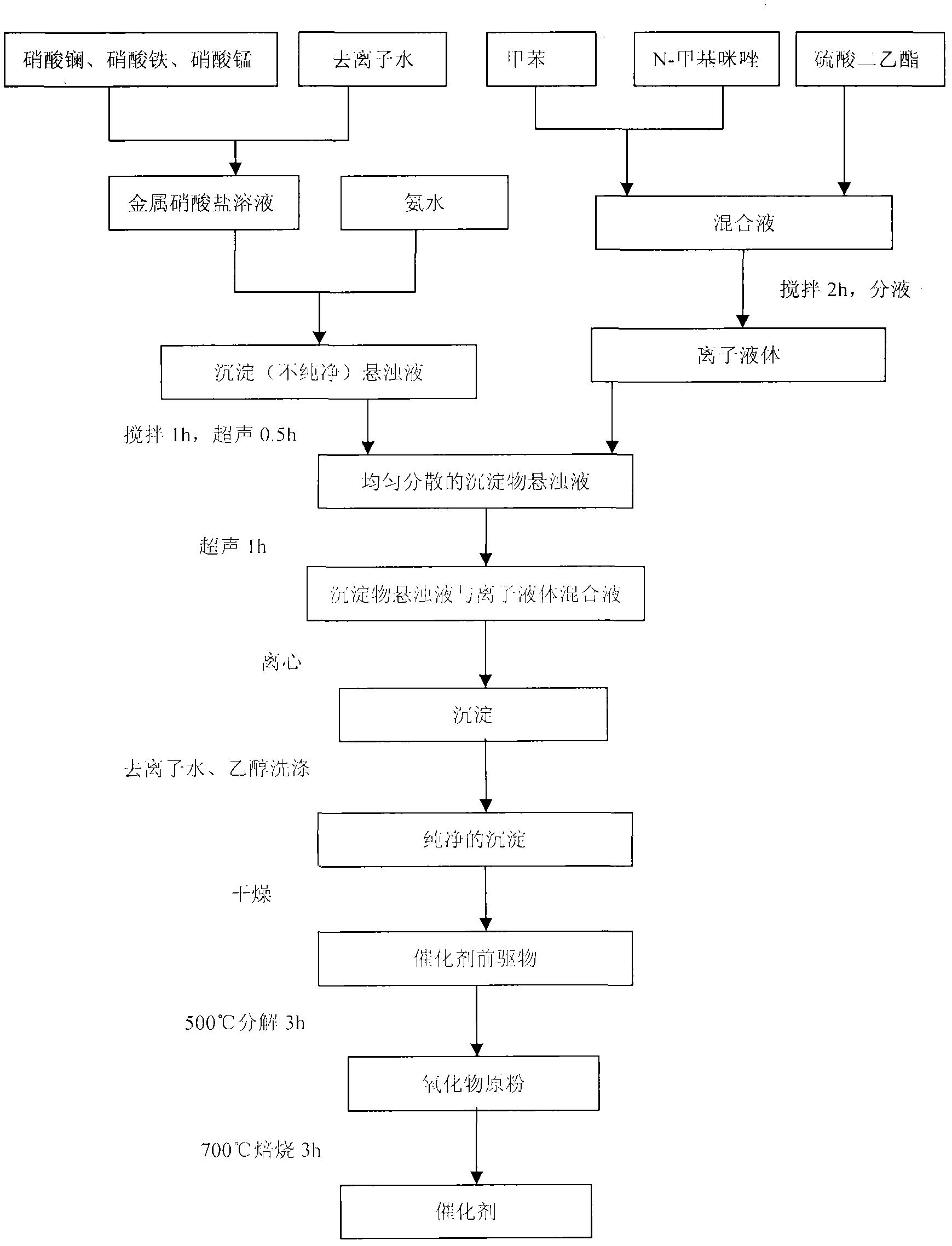

Method used

Image

Examples

Embodiment 1

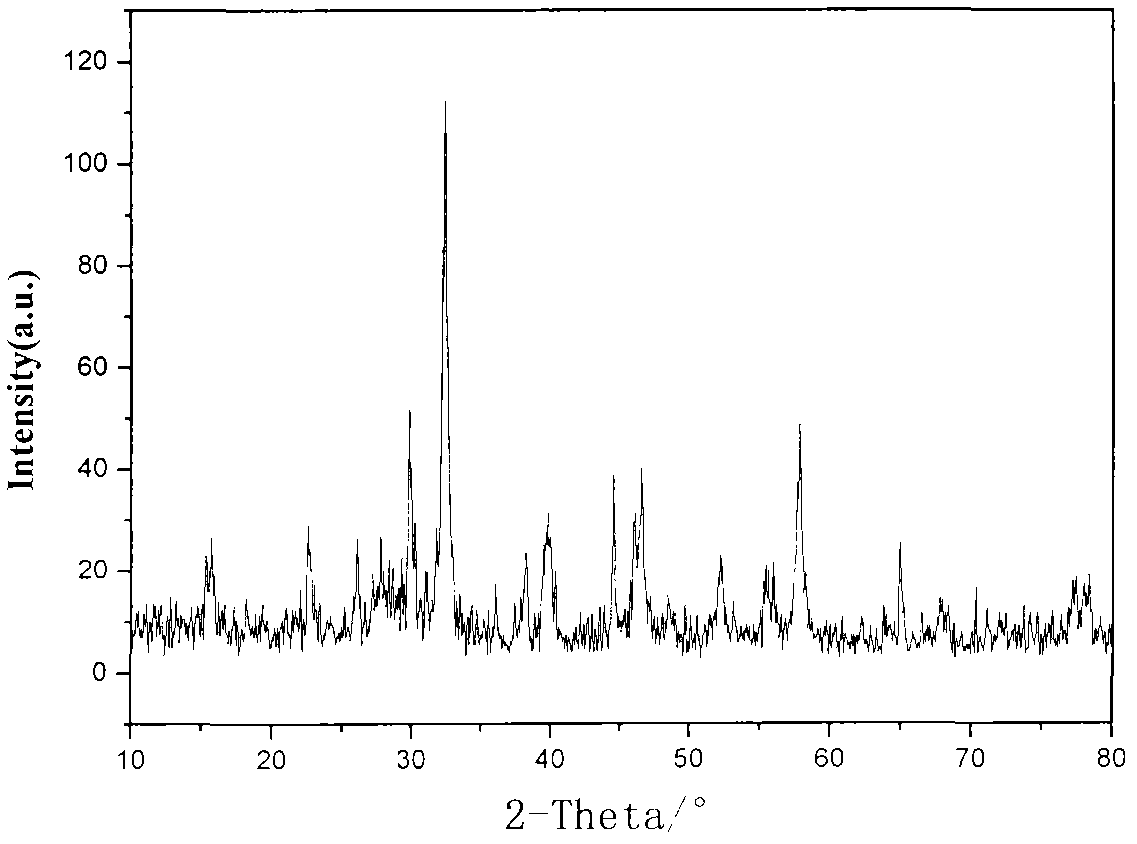

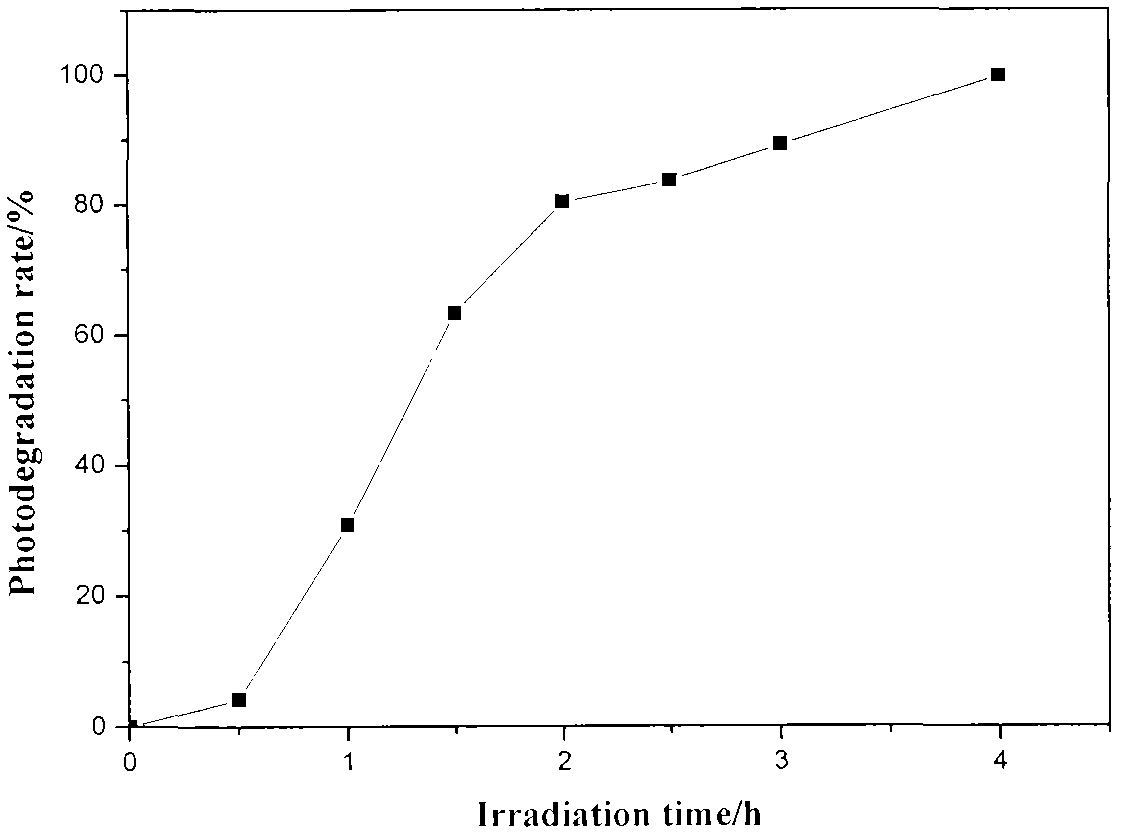

[0015] Embodiment 1: take by weighing 3.2492gLa (NO 3 ) 3 ·nH 2 O, 2.02gFe(NO 3 ) 3 ·6H 2 O and 1.7895g50% Mn(NO 3 ) 3 The solution was dissolved in 140mL deionized water to make a metal nitrate mixed solution. Weigh 3.2844g of N-methylimidazole, mix it with 20mL of toluene, stir in a water bath at 85°C for 45min, add 5.3mL of diethyl sulfate, stir at room temperature for 2h, let stand for liquid separation, remove the lower layer of ionic liquid, and add an appropriate amount of Ammonia water was added to the metal nitrate mixed solution which was constantly stirred, and a precipitate was formed. Stirring was continued for 1 hour, ultrasonic dispersion was carried out for 0.5 hour, then ionic liquid was added, and then ultrasonic dispersion was carried out for 1 hour. The resulting precipitate was washed with deionized water and ethanol to pH 7, respectively. The precipitate was dried in an oven at 100°C in an air atmosphere for 12 hours, then calcined in a muffle fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com