Magnetic biofertilizer and preparation method

A bio-fertilizer and magnetic technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as waste of resources, air pollution, economic losses of the country and the people, and achieve the effects of reducing production costs, enhancing dispersibility and filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

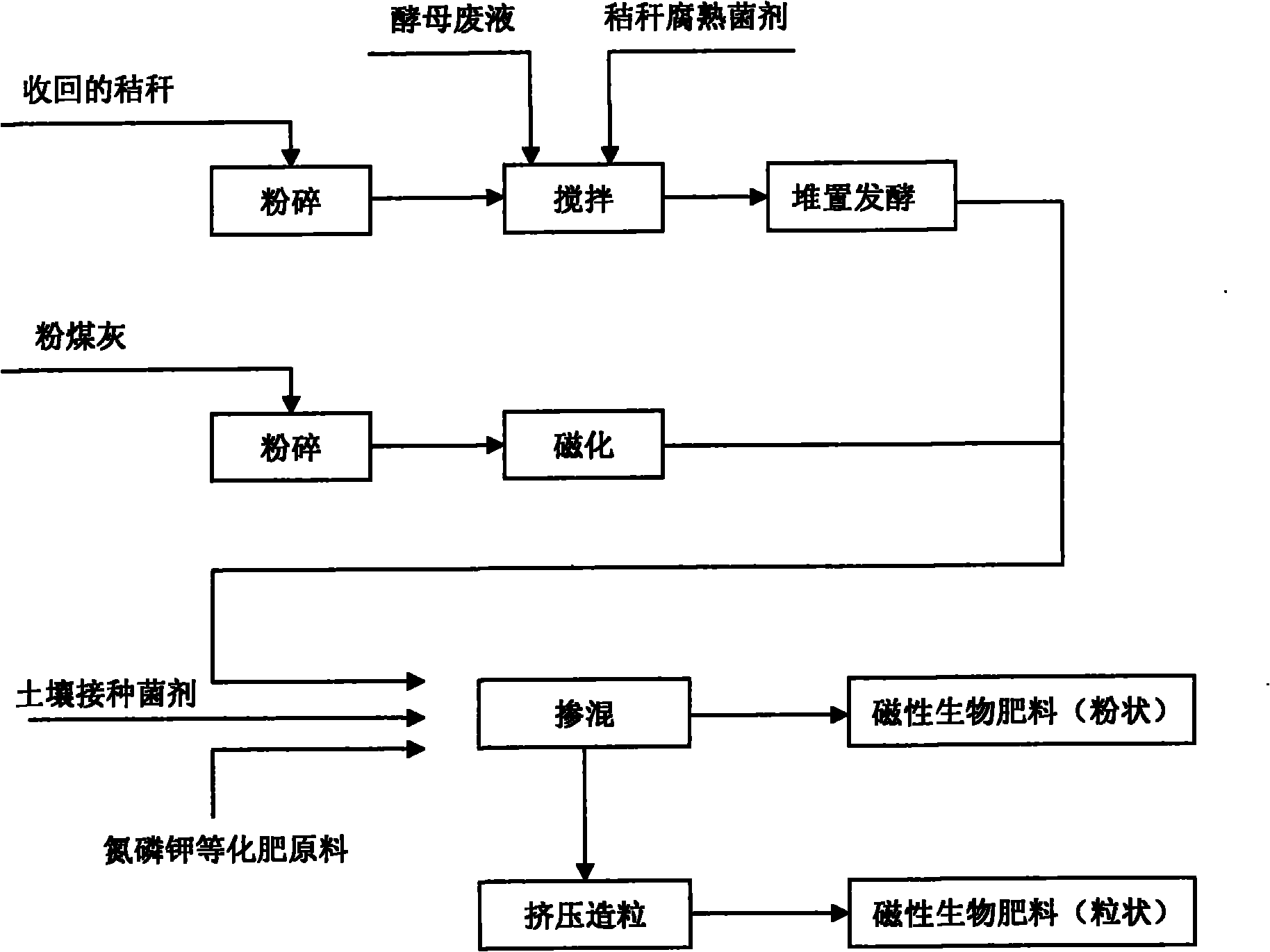

[0032] The method for preparing magnetic biological fertilizer of the present invention, comprises the steps:

[0033] 1. Grind the recovered and dried straws to below 18 mesh for later use, mix 500 kg of crushed straw powder into a mixer, and use a metering pump at the ratio of straw powder: yeast waste liquid = 1:1 during the mixing process Pump the yeast waste liquid with a water content of about 50-60% in the waste liquid storage tank into the mixer, and add 2-4 kg of straw decomposing agent and 3-5 kg of urea, control the water content of the agitator to 20-30%, and stir After uniformity, it is sent to the fermenter for stacking and fermenting for about 15 days. During the fermentation process, the stack is turned twice according to the temperature. Pack into bags after fermentation is complete;

[0034] 2. Crush the returned thermal power plant fly ash to less than 60 mesh, send it to a magnetizer and magnetize it under a magnetic field of about 5000 gauss for 5 secon...

Embodiment 1

[0036] Present embodiment is the example of producing 1000 kilograms of powdery biological fertilizers:

[0037] Take 500 kg of straw yeast mixture fermented in step 1, 400 kg of magnetized fly ash in step 2, and 100 kg of soil inoculant, mix them into a mixer and stir evenly, measure and pack to obtain the powdery magnetic biological fertilizer. Its effective components are organic matter ≥ 25%, nitrogen + phosphorus + potassium ≥ 2%, the number of beneficial microorganisms ≥ 50 million per gram of fertilizer, and trace elements such as silicon, calcium, magnesium, iron, manganese, copper, zinc, molybdenum, etc. More than 15%, the magnetic component is 2.5%.

Embodiment 2

[0039] Present embodiment is the example of producing 1000 kilograms of powdery biological fertilizers:

[0040] Take 450 kg of straw yeast mixture fermented in step 1, 325 kg of fly ash magnetized in step 2, 75 kg of soil inoculant, 80 kg of urea, 50 kg of powdered monoammonium phosphate, and 20 kg of potassium chloride and mix them into a mixer Uniform, measured and packaged to obtain the powdery magnetic bio-fertilizer. Its effective components are organic matter ≥ 20%, nitrogen + phosphorus + potassium ≥ 10%, the number of beneficial microorganisms ≥ 35 million per gram fertilizer, soluble silicon, calcium, magnesium, iron, manganese, copper, zinc, molybdenum and other medium and trace elements It accounts for more than 10%, and the magnetic component is 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com