Preparation method of m-nitroacetophenone

A kind of technology of nitroacetophenone and manufacturing method, applied in directions such as nitro compound preparation, organic chemistry and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

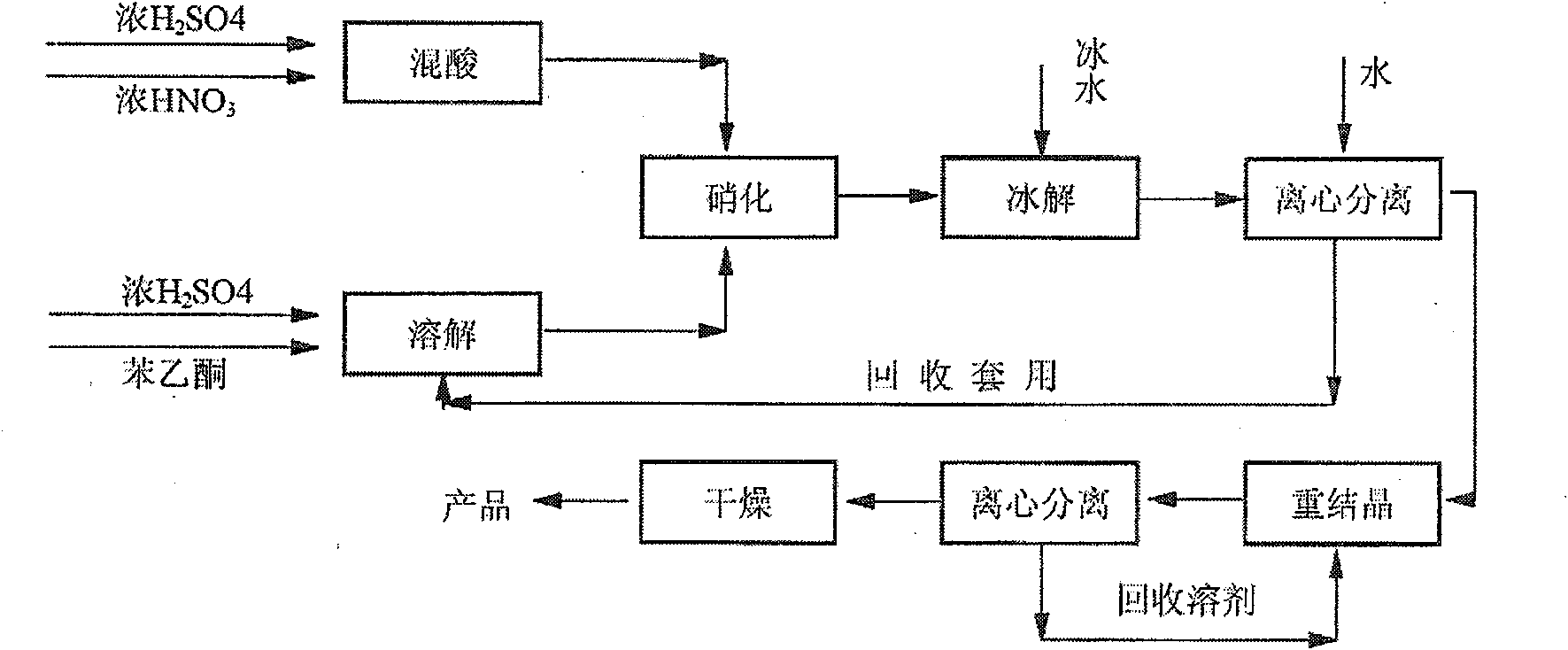

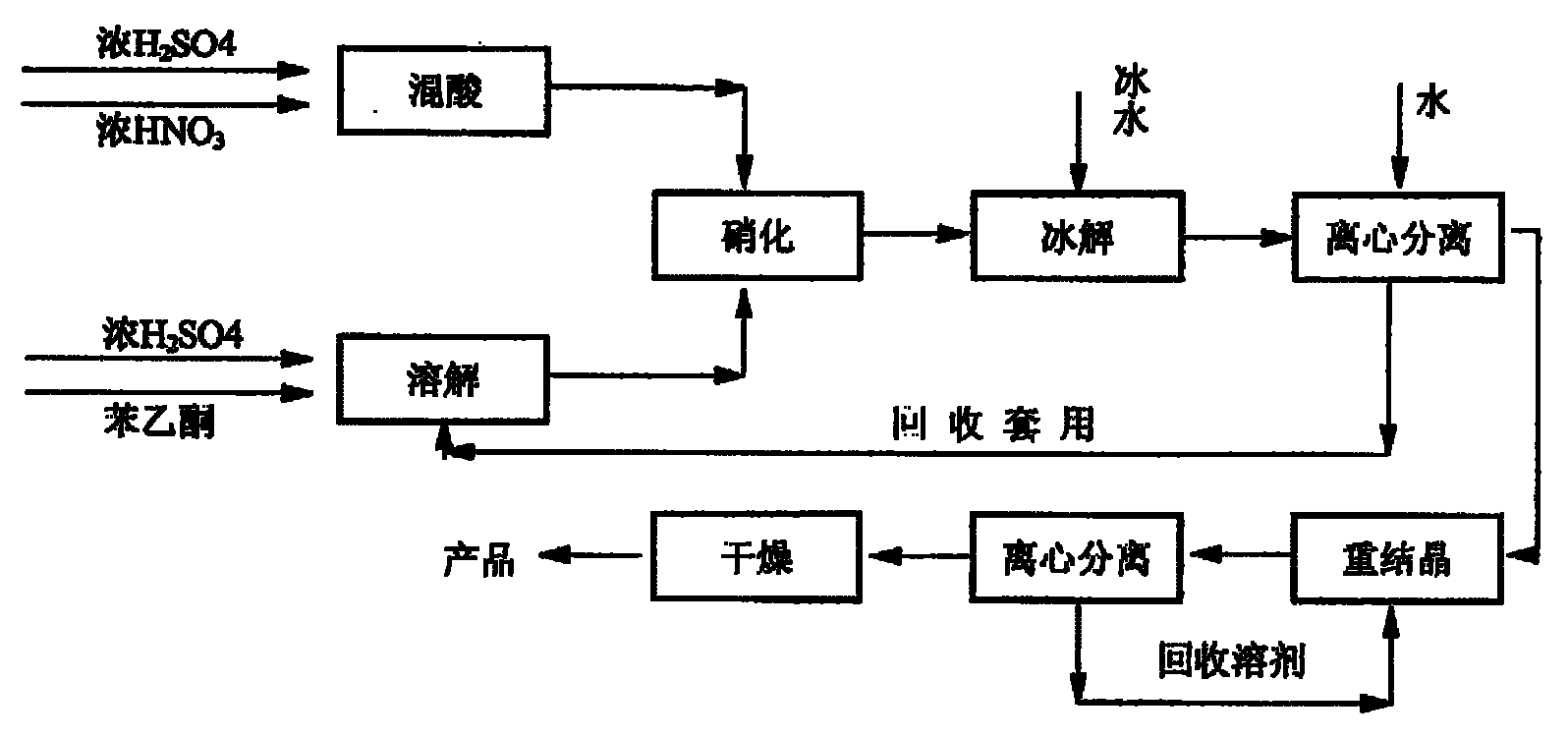

[0006] The technical features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0007] Referring to the attached figure, the 98% H 2 SO 4 Add catalyst and catalyst into the reaction kettle, start stirring, cool down to -8℃~-20℃, add acetophenone to keep the temperature, and slowly add the nitrating agent composed of concentrated nitric acid and concentrated sulfuric acid. During the dropping process, the temperature should be controlled at - Below 8°C, keep stirring for 20-40min, then slowly transfer the reactant to a reaction kettle containing a large amount of ice water under stirring, and control the temperature within 20°C-30°C during the transfer process; the product is solid , washed with clean water to remove acidic substances, then recrystallized with methanol, and finally obtained m-nitroacetophenone product with a purity of ≥99% through alcohol analysis. The dilute acid after centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com