Method and device for rapidly measuring sidewall appearance of micro-nano deep groove structure

A measurement method and deep groove technology, applied in the direction of measurement devices, optical devices, semiconductor/solid-state device testing/measurement, etc., can solve problems such as measurement result errors, and achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

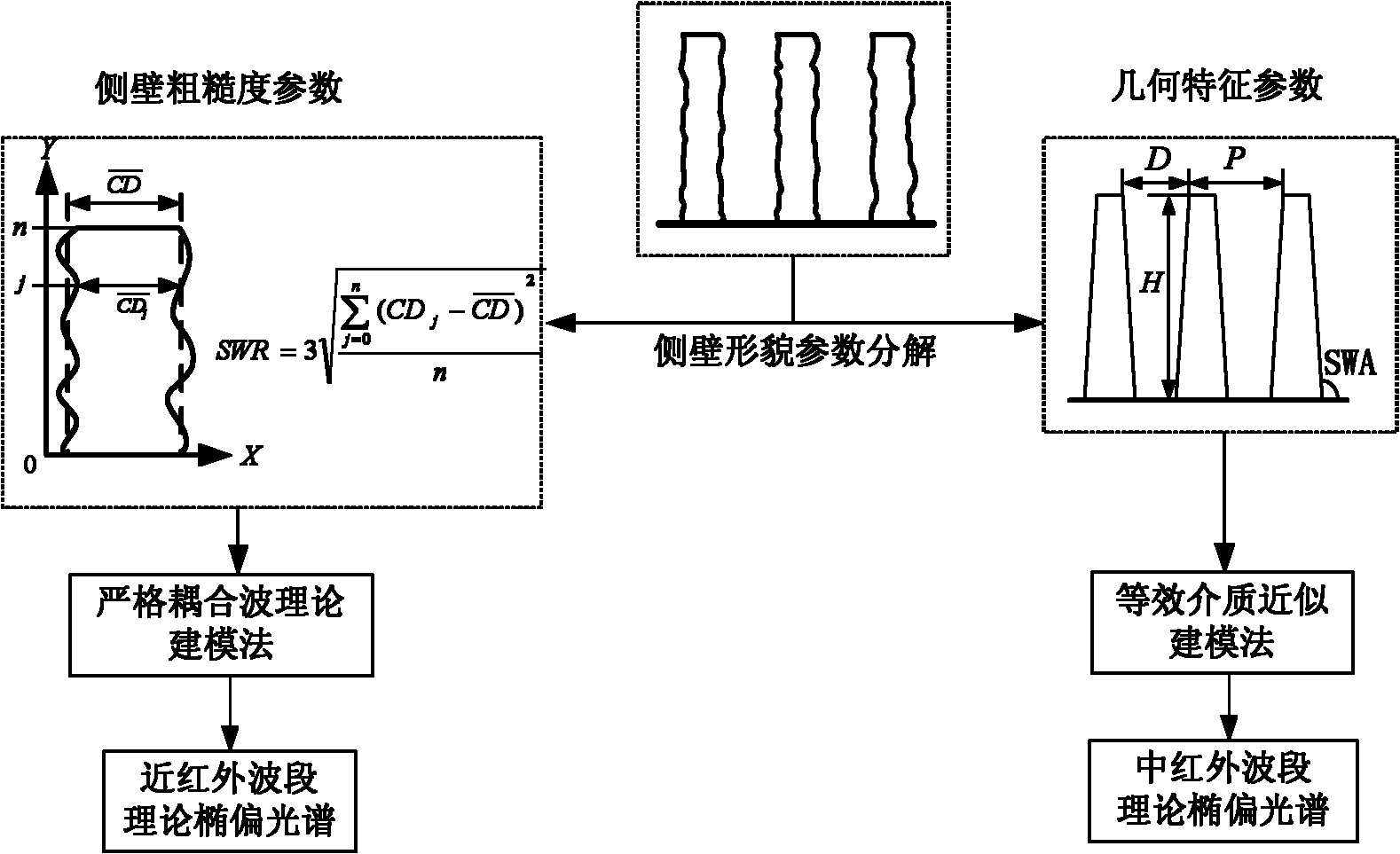

Method used

Image

Examples

Embodiment Construction

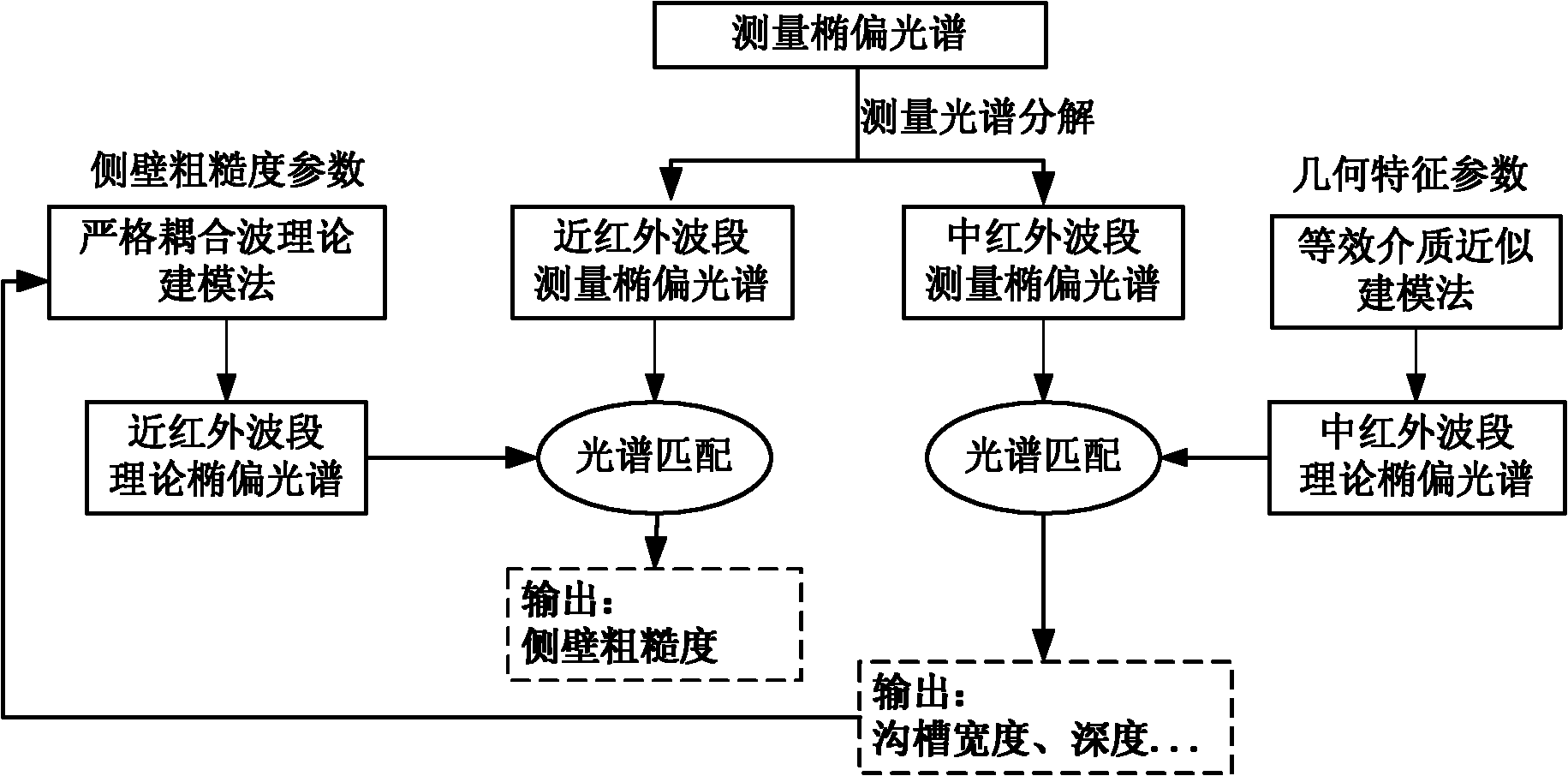

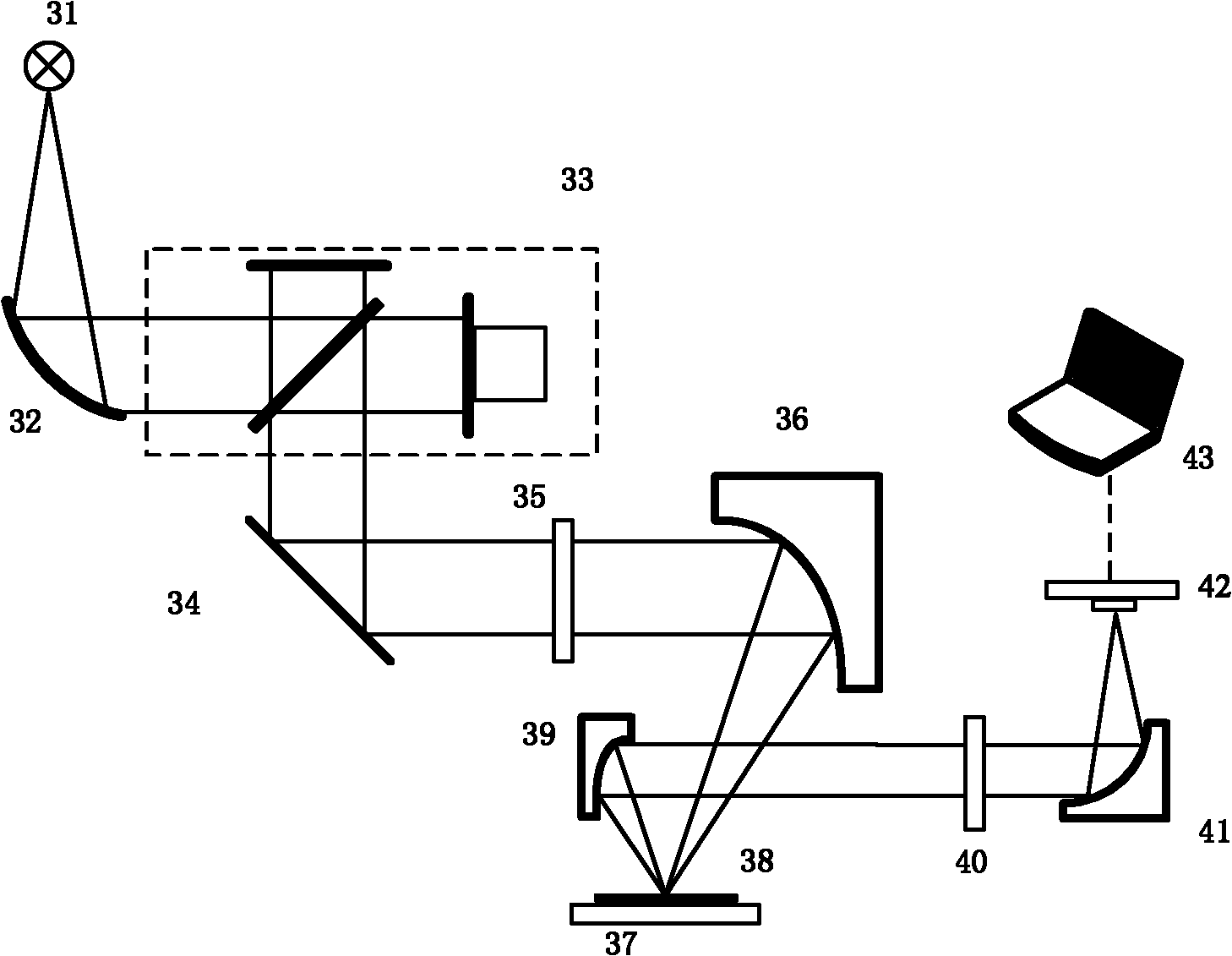

[0019] The principle and working process of the method of the present invention will be further described in detail below by taking the measurement process of the inclined-wall deep groove structure as an example and referring to the accompanying drawings.

[0020] The realization step of the inventive method comprises:

[0021] (1) After the infrared beam is polarized by the polarizer, it is projected onto the surface of the object to be tested that contains a deep groove structure. The infrared beam is located in the range of near-infrared to mid-infrared, and the wavelength is 0.8-20um;

[0022] (2) After the incident beam is reflected by each surface of the groove structure, it is analyzed by a polarizer, and the reflected signal is received by an infrared detector to obtain an interference signal;

[0023] (3) Perform Fourier transform on the interference signal measured by the infrared detector to obtain the infrared ellipsometric spectrum of the deep groove structure; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com