Method for realizing self-cleaning by performing superhydrophobic modification treatment on surface of substrate

A superhydrophobic modification and self-cleaning technology, which is applied in the field of self-cleaning, can solve the problems of high cost, harsh experimental conditions, and practical application limitations, and achieve the effect of low raw material cost, self-cleaning and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Cleaning: Sonicate the silicon wafer in water, ethanol, and acetone for 5 minutes in sequence, dry at 105°C for 5 minutes, take it out and put it at room temperature;

[0021] The second step: UV irradiation for 5 minutes;

[0022] The third step: prepare a superhydrophobic coating on the substrate: immerse the substrate treated in the second step above in 1% octadecyltrichlorosilane / toluene solution for 2 minutes, wash twice with toluene, heat at 105°C for 5 minutes, put to room temperature, a self-cleaning surface with superhydrophobic properties is obtained.

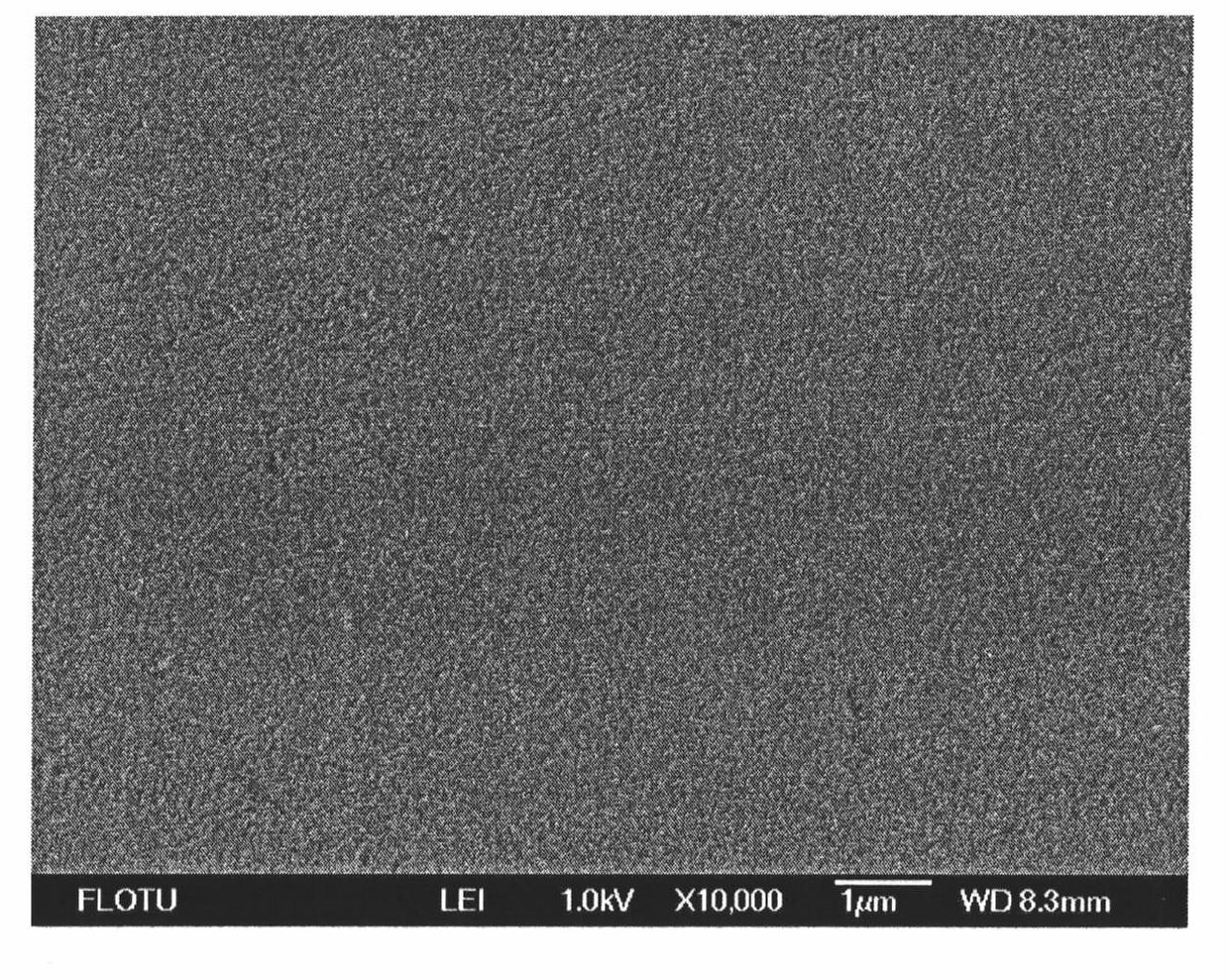

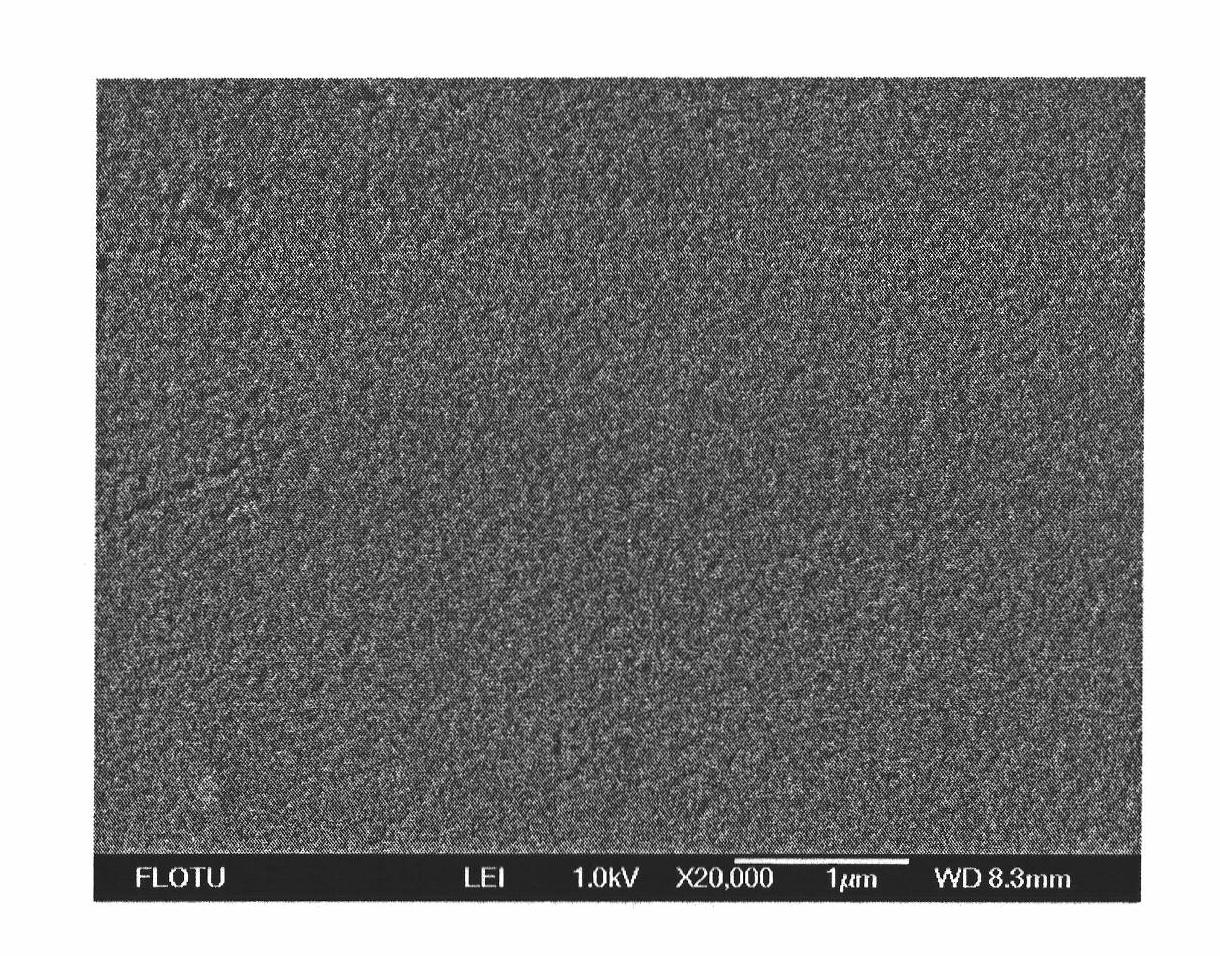

[0023] Adopt scanning electron microscope (JSM-7401F) to scan the surface topography of the superhydrophobic silicon wafer substrate that the present invention makes, as figure 1 As shown, the results show that there is a nanoscale rough structure on the superhydrophobic surface, which meets the roughness required for superhydrophobic performance.

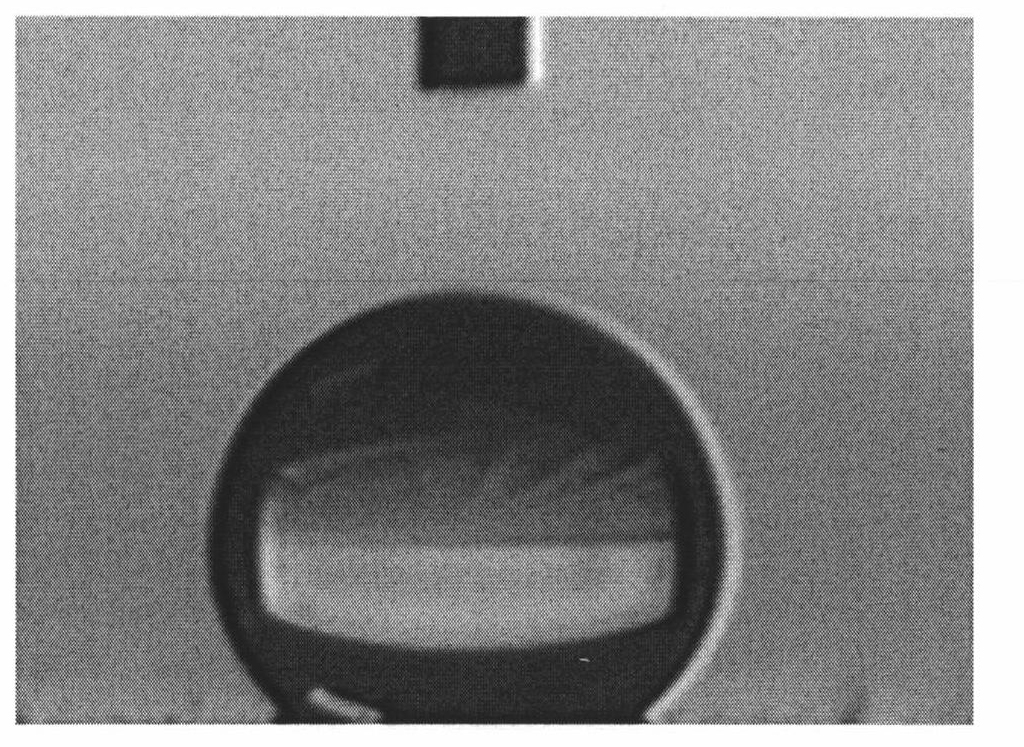

[0024] The superhyd...

Embodiment 2

[0026] Based on polyethylene terephthalate (polyester) film

[0027] The self-assembly chemical reaction process of the polymer matrix of the present embodiment is:

[0028] (1) Silane buffer layer and UV light

[0029]

[0030] (2) Hydrophobic polymer surface preparation

[0031]

[0032] Concrete preparation steps are:

[0033] Step 1: Cleaning: Ultrasonic the polyester film in water, ethanol, and acetone for 5 minutes, then dry it at 105°C for 5 minutes, take it out and put it at room temperature;

[0034] The second step: prepare the silane buffer layer: immerse the substrate treated in the first step above in a 1% concentration of p-aminopropyltriethoxysilane / acetone solution for 5 minutes, take out the acetone and wash it once, heat at 105°C for 10 minutes, put to room temperature;

[0035] The third step: UV irradiation for 5 minutes;

[0036] Step 4: Prepare a superhydrophobic coating on the substrate: immerse the substrate treated in the third step above in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com