Preparation method for ozone catalytic oxidation catalyst and device using catalyst

An ozone catalytic oxidation and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low utilization rate of devices, long reaction time and increased cost and other problems, to achieve the effect of good removal, shortened processing cycle and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

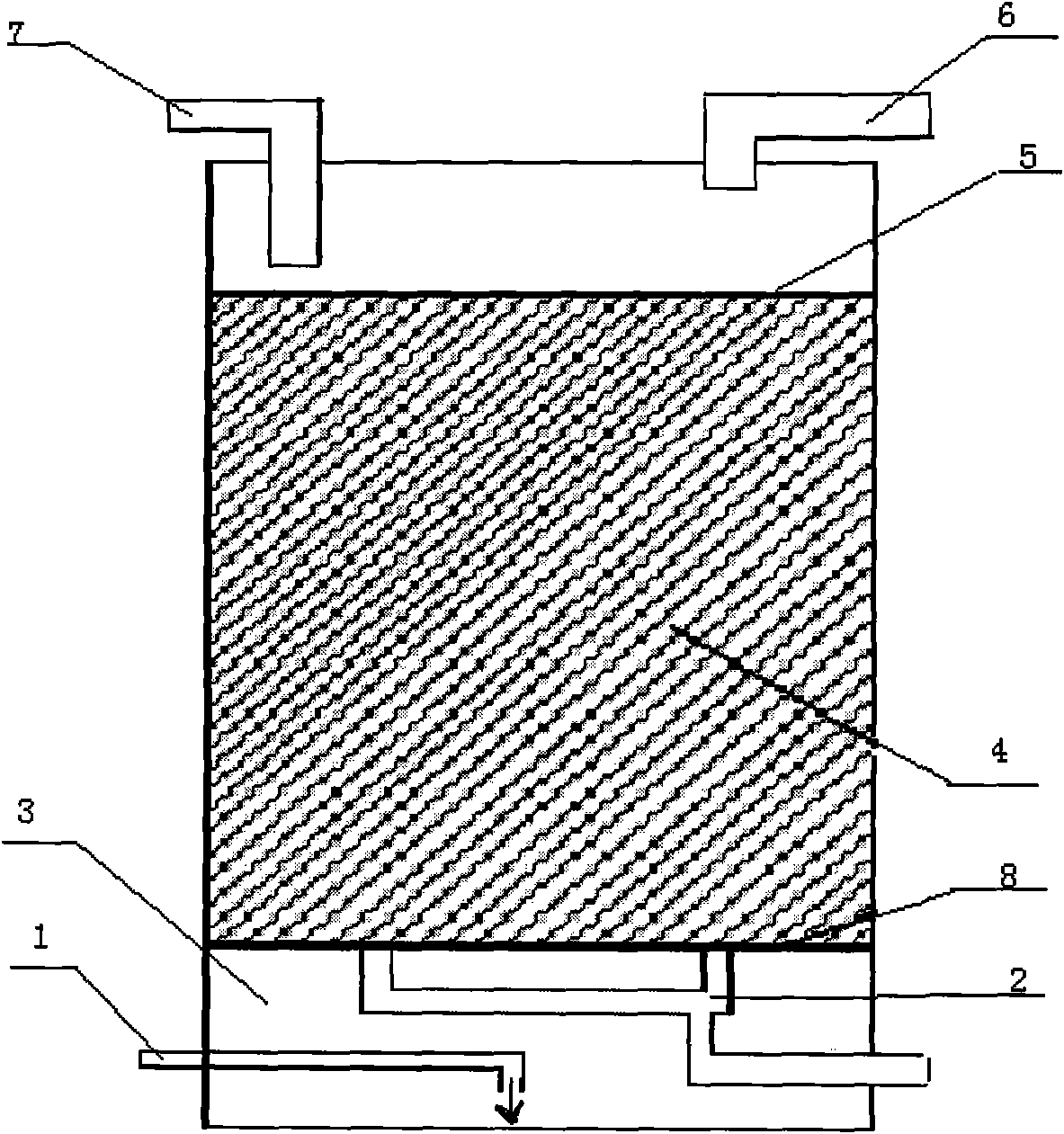

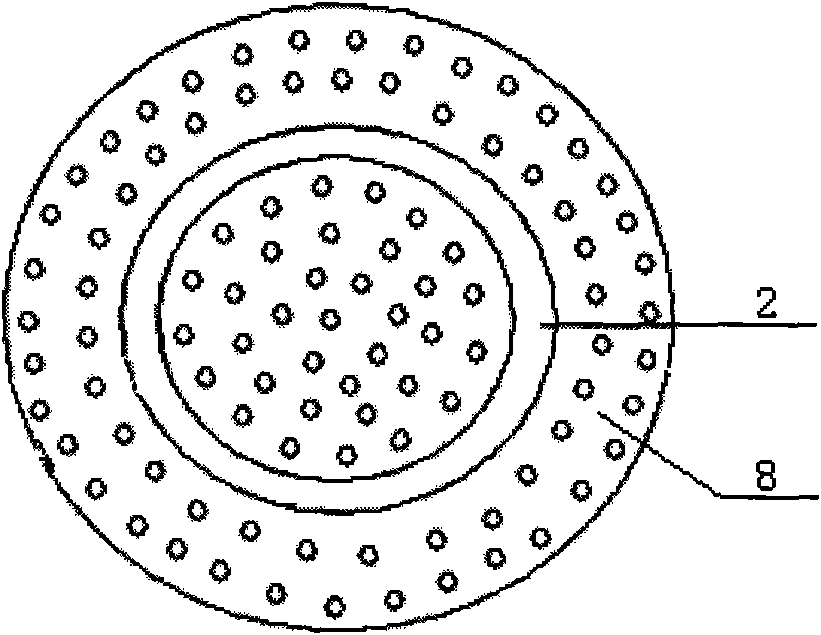

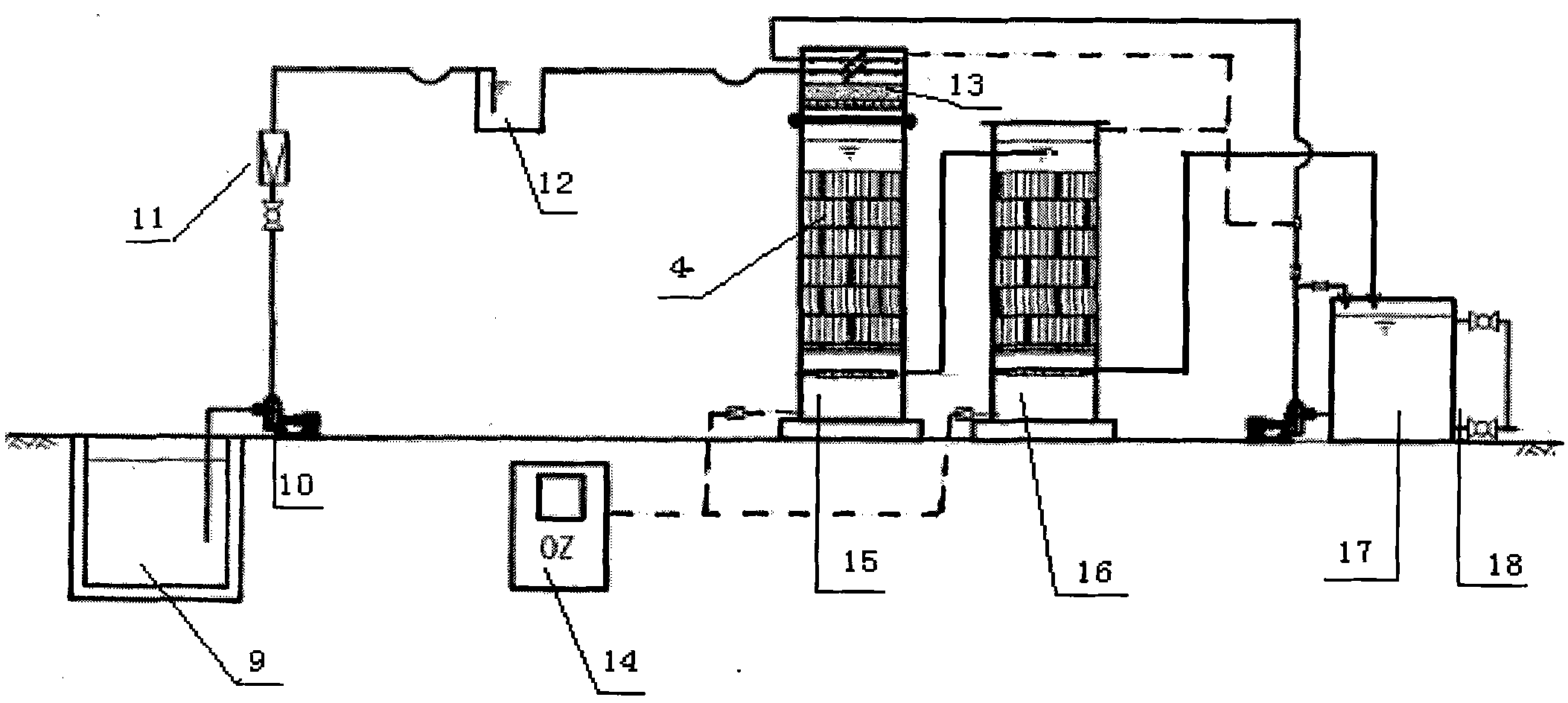

[0021] Fe in this embodiment 2 o 3 The preparation method of supported catalyst is as follows: take gac as carrier, prepare ferric chloride solution by 3wt% load, add pyrophosphate of 0.2wt‰, gac is soaked in this solution for 8 hours, add 1wt% alkali to continue soaking 8 hours, dried at 105° C. for 6 hours, then washed and dried, placed in a muffle furnace at 400° C. for 2 hours and calcined to obtain a solid catalyst.

Embodiment 2

[0023] The preparation method of the Fe-Mn supported catalyst of the present embodiment is as follows: use activated carbon as a carrier, prepare a mixed solution with a Fe:Mn molar ratio of 1:1 by 3wt% load, add 0.2wt‰ potassium pyrophosphate, impregnate the activated carbon Soak in the solution for 8 hours, add 1% alkali and continue soaking for 8 hours, dry at 105°C for 6 hours, then wash and dry, and place in a muffle furnace for calcination at 400°C for 2 hours to obtain a solid catalyst.

Embodiment 3

[0025] In this implementation, the activated carbon loaded with iron-manganese composite oxide obtained in Example 2 was used as a catalyst for ozone catalytic oxidation treatment of disperse dye wastewater. The COD removal rate of the catalyst prepared by roasting at 400°C is 72.02%, and the effluent is colorless and odorless, which can meet the discharge standard of industrial water treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com