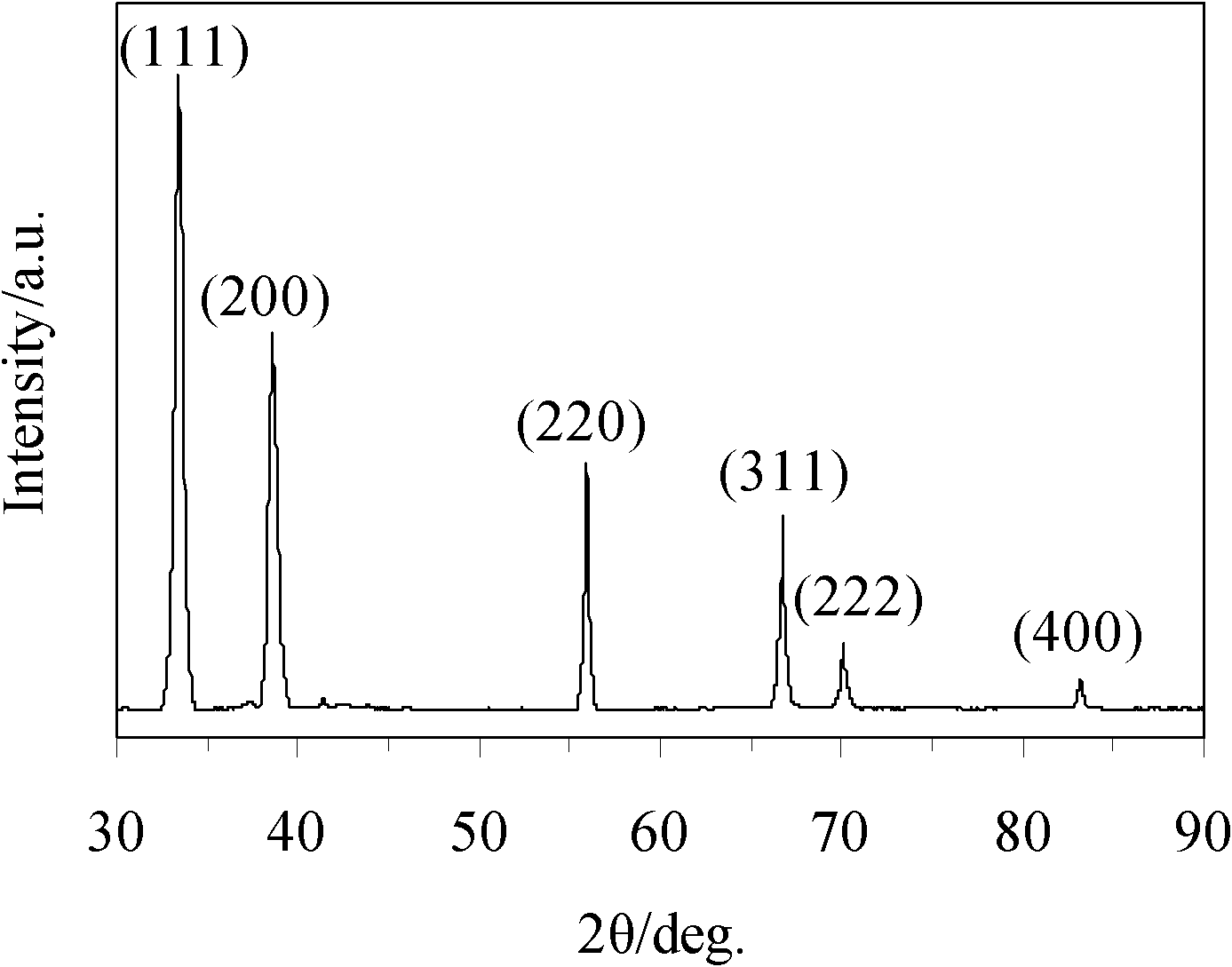

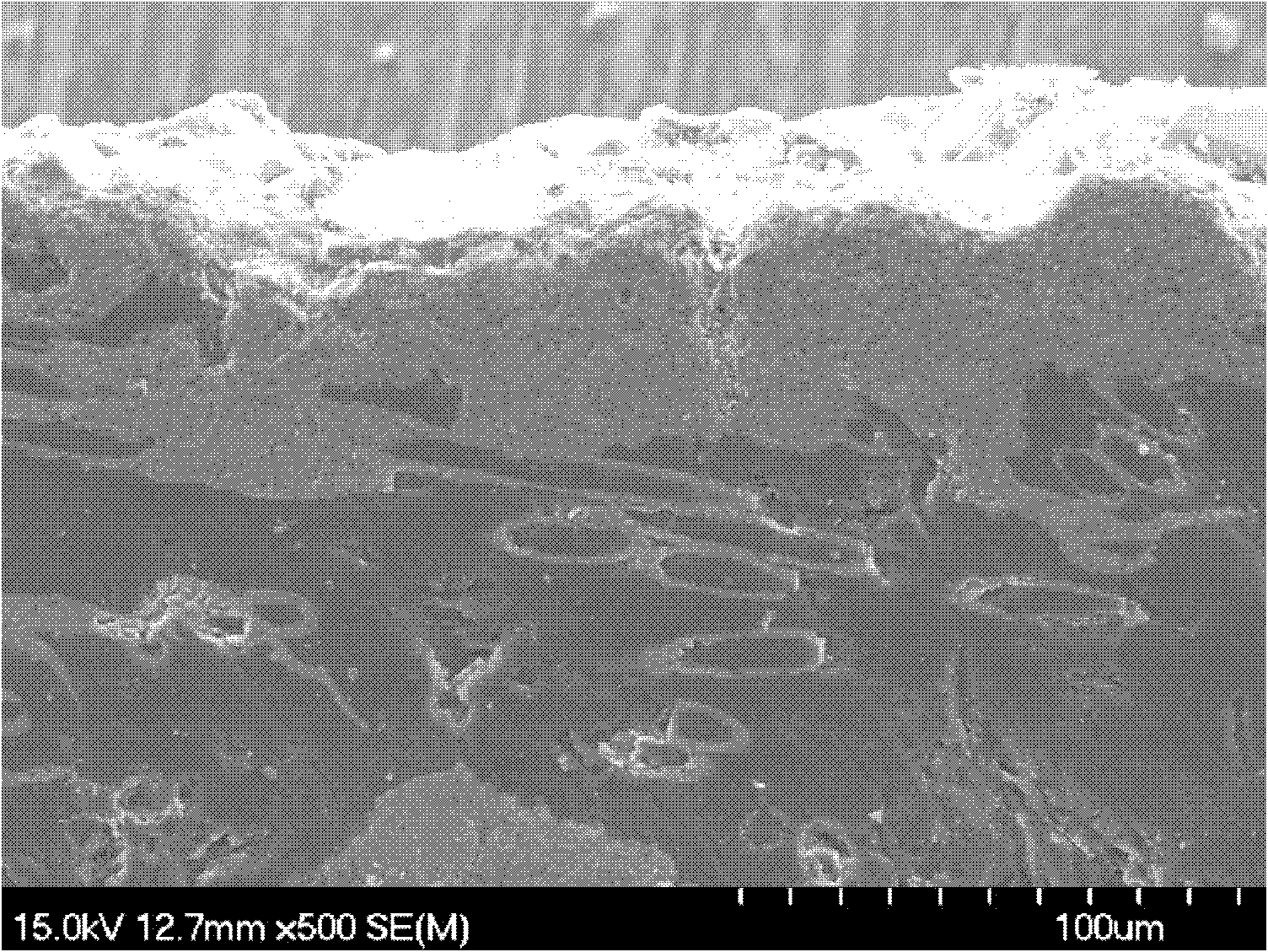

Preparation method for ablation-resistant coating made of carbon/carbon composite material HfC

A carbon composite material and anti-ablation technology, applied in the field of high temperature resistant materials, can solve the problems of equipment corrosion, low bonding strength between coating and substrate, etc., and achieve the effects of improving bonding strength, reducing residual stress and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Grind and polish the carbon / carbon composite material with No. 400, No. 800, and No. 1200 SiC water-grinding paper in sequence, then ultrasonically clean it in acetone for 20 minutes, and put it in an oven at a temperature of 100°C to dry;

[0026] (2) Add Hf powder, rare earth metal oxide powder, AlN powder and graphite powder into an alumina ball mill jar and mix to obtain a mixture, then add ethyl acetate and nitro varnish into the ball mill jar, and ball mill and mix for 24 hours to prepare a slurry ; The mass percentage of Hf powder in the mixture is 70%, the mass percentage of rare earth metal oxide powder is 15%, the mass percentage of AlN powder is 5%, graphite powder is surplus, and described rare earth metal oxide powder is La 2 o 3 Powder, the mass sum of the ethyl acetate and nitro varnish is 50% of the mixture mass; the mass ratio of the ethyl acetate and nitro varnish is 2:1;

[0027] (3) Evenly brush the slurry on the surface of the dried carbon / carb...

Embodiment 2

[0033] This embodiment is the same as Embodiment 1, and the difference is that the rare earth metal oxide powder used is Er 2 o 3 、Sc 2 o 3 、Lu 2 o 3 , La 2 o 3 , Yb 2 o 3 、Ce 2 o 3 and Gd 2 o 3 One of, or Y 2 o 3 、Er 2 o 3 、Sc 2 o 3 、Lu 2 o 3 , La 2 o 3 , Yb 2 o 3 、Ce2 o 3 and Gd 2 o 3 At least two of the

[0034] The HfC anti-ablation coating prepared in this example has a high bonding strength with the carbon / carbon composite material, and the coating is dense and uniform without cracks.

Embodiment 3

[0036] (1) Grind and polish the carbon / carbon composite material with No. 400, No. 800, and No. 1200 SiC water-grinding paper in sequence, then ultrasonically clean it in ethanol for 40 minutes, and dry it in an oven at a temperature of 200 ° C;

[0037] (2) adding Hf powder, rare earth metal oxide powder, AlN powder and graphite powder into a polyurethane ball mill tank and mixing to obtain a mixture, then adding ethyl acetate and nitrovarnish to the ball mill tank, and ball milling and mixing for 48 hours to prepare a slurry; The mass percentage of Hf powder in the mixture is 89%, the mass percentage of rare earth metal oxide powder is 5%, the mass percentage of AlN powder is 1%, graphite powder is balance, and described rare earth metal oxide powder is Sc 2 o 3 Powder, the mass sum of the ethyl acetate and the nitro varnish is 100% of the mass of the mixture; the mass ratio of the ethyl acetate and the nitro varnish is 1:1;

[0038] (3) Evenly brush the slurry on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com