Method for preparing alpha-Fe2O3-coated pearlescent pigment by low-temperature catalysis

A pearlescent pigment and low-temperature catalysis technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of complex process and high energy consumption, and achieve the effect of simple preparation process, energy saving and pure color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

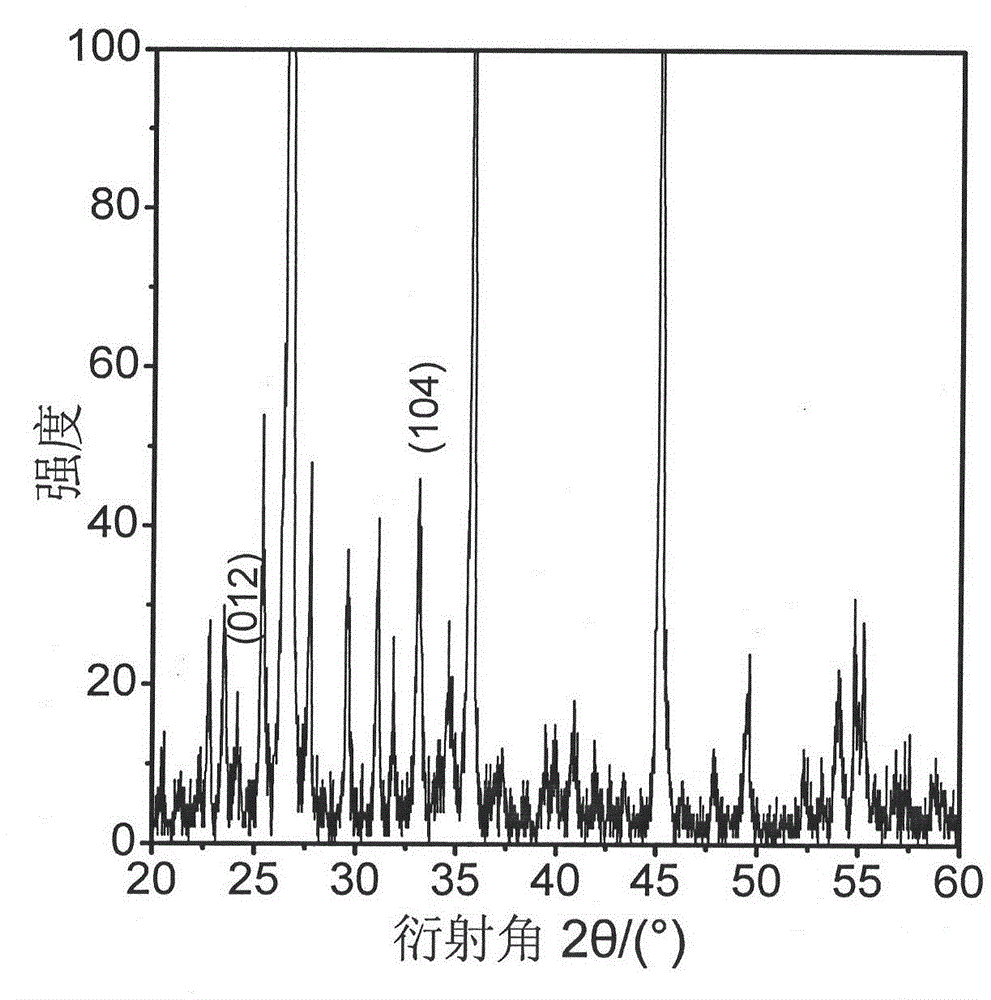

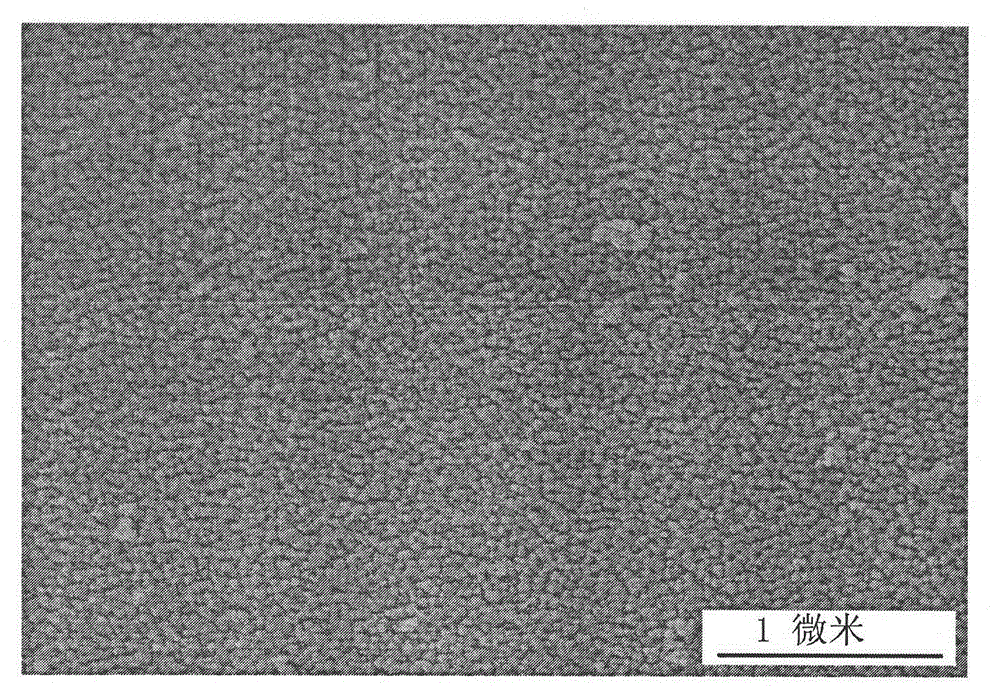

[0016] First, weigh 10g of mica particles, put them into a four-necked flask in an electronic constant temperature water bath, add 300ml of deionized water, raise the temperature of the solution to 75°C, adjust the pH of the solution to 3.5, and add 0.2ml of Slowly add 25ml of 0.5mol / L FeCl at the speed of / min 3 Solution, add 1.52mol / L NaOH solution at the same time to keep the pH of the solution constant, after the addition is completed, press Fe 2+ with Fe 3+ The molar ratio is 0.04:1 by adding FeCl 2 Solution, the pH value of the mixed solution was adjusted to 7 with NaOH solution, and the temperature of the mixed solution was raised to 100° C. to react for 2 hours, then suction filtered, washed and dried to finally obtain the mica pearlescent pigment. X-ray diffraction results show that the oxide coated on the mica is α-Fe 2 o 3 (Such as figure 1 shown), and the coating layer is dense and uniform (such as figure 2 shown).

Embodiment 2

[0018] First, weigh 10g of mica particles, put them into a four-neck flask in an electronic constant temperature water bath, add 300ml of deionized water, raise the temperature of the solution to 75°C, adjust the pH of the solution to 3.5, and add 0.5ml of Slowly add 25ml of 0.5mol / L Fe at the speed of / min 2 (SO 4 ) 3 Solution, add 1.52mol / L NaOH solution at the same time to keep the pH of the solution constant, after the addition is completed, press Fe 2+ with Fe 3+ The molar ratio of 0.04:1 was added to FeSO 4 solution, adjust the pH value of the mixed solution to 7 with NaOH solution, and raise the temperature of the mixed solution to 100°C for 2 hours of reaction, then suction filter, wash and dry, and finally obtain dense, uniform and stable α-Fe 2 o 3 Encapsulated Pearlescent Pigment, α-Fe 2 o 3 The coverage rate is 9.09%.

Embodiment 3

[0020] First, weigh 10g of mica particles, put them into a four-neck flask in an electronic constant temperature water bath, add 300ml of deionized water, raise the temperature of the solution to 75°C, adjust the pH of the solution to 3.5, and add 0.5ml of Slowly add 25ml of 0.5mol / L Fe(NO 3 ) 3 Solution, add 1.52mol / L NaOH solution at the same time to keep the pH of the solution constant, after the addition is completed, press Fe 2+ with Fe 3+ The molar ratio is 0.04:1 by adding FeCl 2 solution, adjust the pH value of the mixed solution to 7 with NaOH solution, and raise the temperature of the mixed solution to 100°C for 2 hours of reaction, then suction filter, wash and dry, and finally obtain dense, uniform and stable α-Fe 2 o 3 Encapsulated Pearlescent Pigment, α-Fe 2 o 3 The coverage rate is 9.09%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com