Environment-friendly interior wall latex paint with low heat conducting capacity

A technology of latex paint and low thermal conductivity for interior walls, applied in latex paint, coating, etc., can solve the problems of lack of heat protection and heat preservation, environmental protection and energy saving, heat preservation and heat insulation, etc. Effects of heat radiation and heat loss, increased dosage, and prevention of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 25.0 parts of water based on 100 parts by weight, and add dispersant polyacrylic acid sodium salt 5040: 1.6 parts, hydroxyethyl cellulose 250HBR thickener: 0.2 parts, American Gas at a speed of 400 to 700 rpm Chemical SA8 wetting agent: 0.2 parts, A10 defoamer: 0.6 parts, disperse for 5 minutes; at 600-1000 rpm, add titanium dioxide: 21.7 parts, hollow glass microspheres S38 10.0 parts, at 1000-1000 rpm At 1300 rpm, disperse for 20-30 minutes; quality inspection sampling inspection fineness ≤ 60 micron; Mold agent Rohm and Haas LXE: 0.5 parts, disperse for 5 minutes, then add PH regulator ammonia water: 0.2 parts, disperse for 5 minutes; quality inspection sampling inspection; filter and pack after passing.

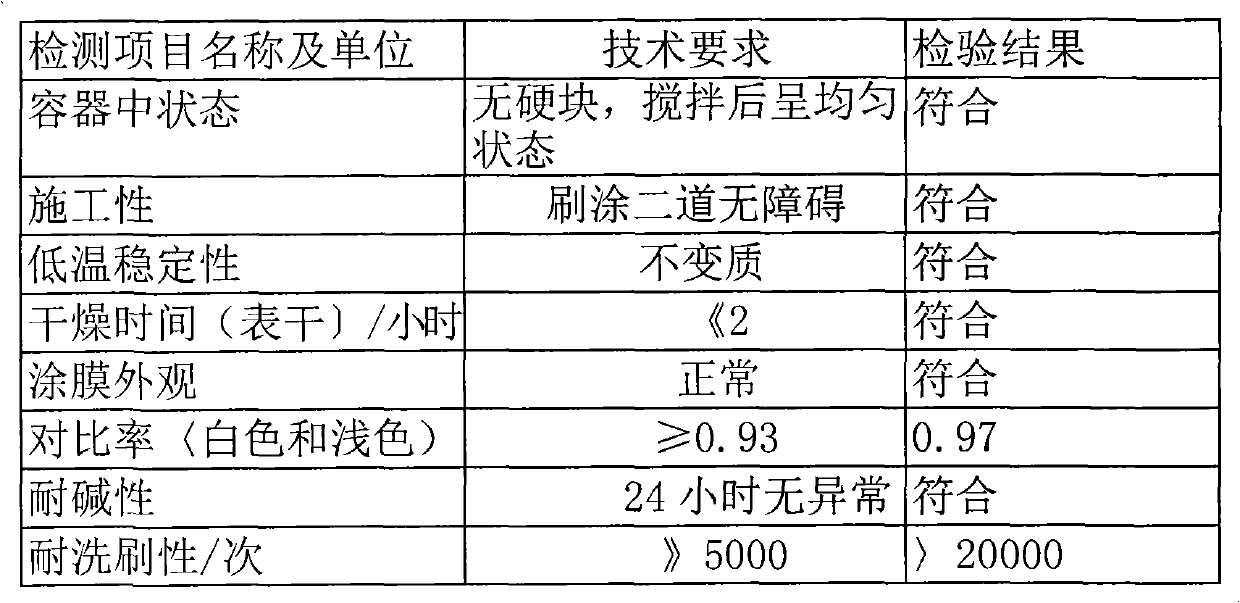

[0042] According to the described method and proportion, according to the national standard GB / T9756-2009 "Synthetic Resin Emulsion Interior Wall Paint" standard test, its various performance indicators all meet the national standard.

[0043]

[0044] As...

Embodiment 2

[0048]Weigh 23.00 parts of water according to 100 parts by weight, and put in the mixture of dispersant polyhydroxy acid ammonium salt 5027 and modified polyacrylic acid sodium salt 731A at a speed of 400-700 rpm: 0.8 parts, hydroxyethyl fiber Su QP15000H thickener: 2.8 parts, American Gas Chemical SA9 wetting agent: 0.2 parts, A34 defoamer: 0.25 parts, disperse for 5 minutes; at 600-1000 rpm, add titanium dioxide and heavy calcium powder in turn Mixture: 15.0 parts, hollow glass microsphere S15 20.0 parts, at 1000-1300 rpm, disperse for 20-30 minutes; quality inspection sampling test fineness ≤ 60 microns; at 300-600 rpm , followed by adding film-forming aid Celanese 1608: 37.5 parts, bactericidal and antifungal agent Sol’s ACTICIDE MV: 0.3 parts, after dispersing for 5 minutes, then adding PH regulator AMP-95: 0.15 parts, and dispersing for 5 minutes; Sampling and inspection; filter and pack after passing the test.

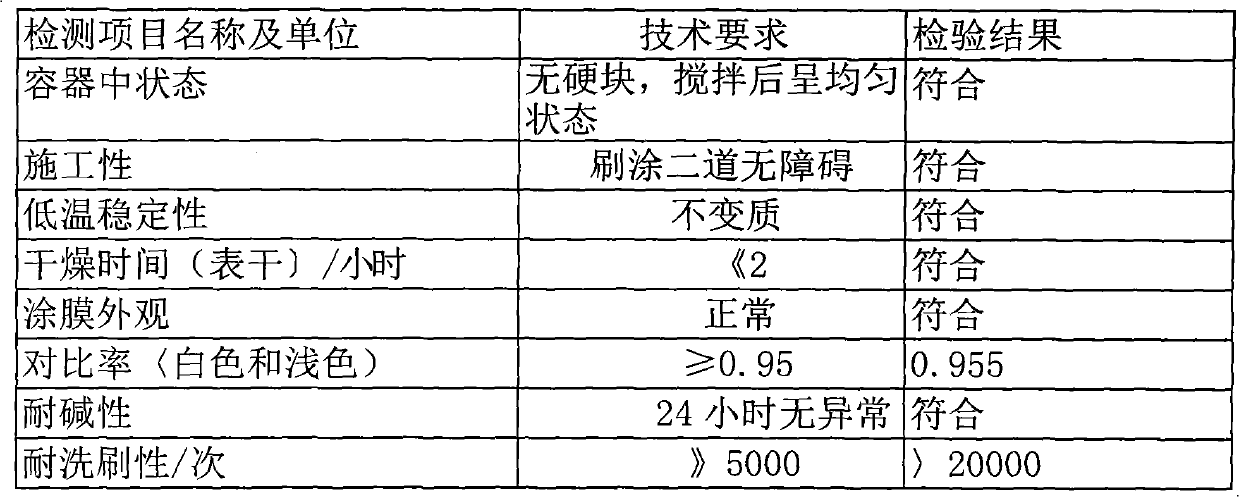

[0049] According to the described method and proportion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com